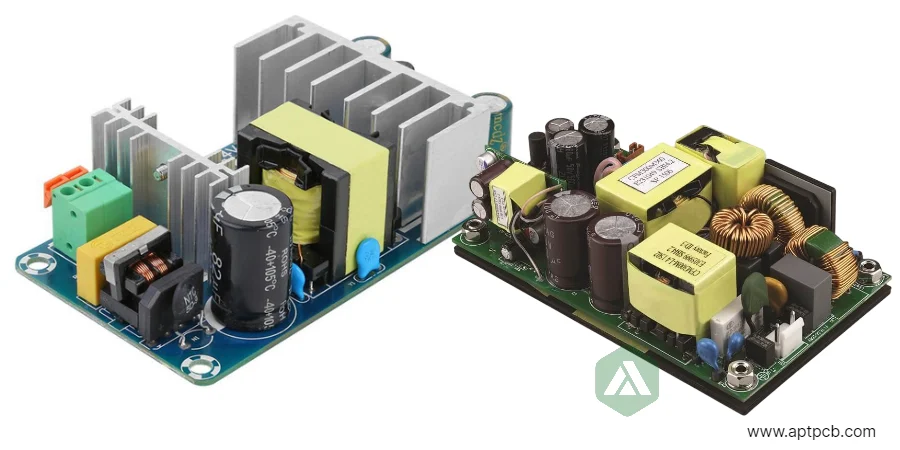

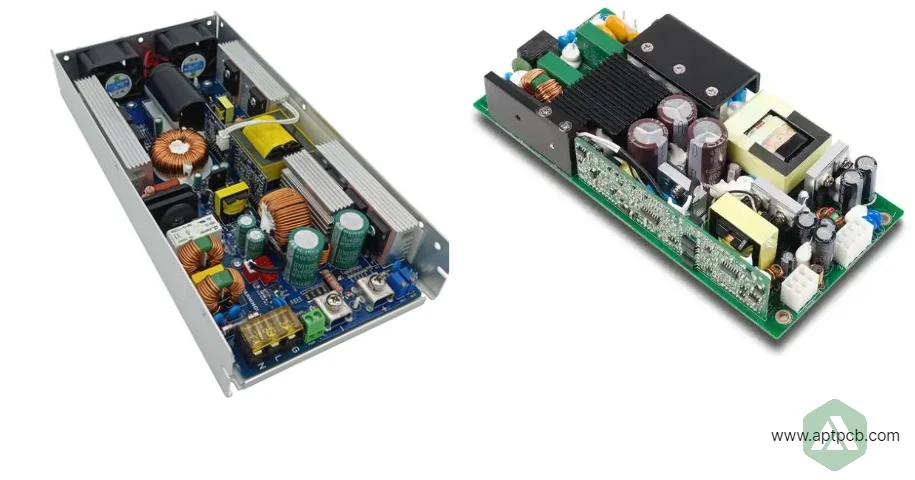

AC-DC power supply PCBs convert mains voltage (85-265VAC worldwide) to isolated, regulated DC outputs with power factor correction, safety isolation, and efficiency standards compliance across medical devices, industrial equipment, telecommunications infrastructure, and consumer electronics requiring reliable mains-powered operation supporting critical applications, life-safety systems, and everyday consumer products through 50,000+ hour operational lifetimes.

At APTPCB, we manufacture AC-DC power supply PCBs implementing flyback, forward, and resonant topologies with multilayer PCB construction achieving reinforced isolation, optimized thermal management, and EMC compliance. Our capabilities support 5W USB chargers through 2kW industrial supplies with comprehensive safety certifications enabling global market access.

Implementing Universal Input and PFC

Universal input AC-DC supplies accept 85-265VAC enabling single design supporting global markets without voltage selection switches or regional variants. Power factor correction shapes input current achieving PF >0.9 and THD <10% meeting EN 61000-3-2 limits mandatory in Europe and increasingly adopted worldwide improving grid compatibility and regulatory compliance.

At APTPCB, our manufacturing implements validated PFC and input stages ensuring global compliance.

Key Input Stage Design

Bridge Rectifier and PFC

- Full-bridge rectification converting AC to pulsating DC for PFC boost converter with heavy copper PCB handling inrush currents

- Active PFC boost converter regulating 380-400VDC bus while shaping input current to follow voltage waveform

- PFC controller ICs implementing average current mode control achieving >0.95 power factor

- Bulk capacitors providing energy storage for holdup time requirements (typically 16ms minimum)

- Inrush current limiting using NTC thermistors preventing excessive surge during startup

- Wide input range operation maintaining regulation from 90VAC through 305VAC

EMI Filter Integration

- Common-mode and differential-mode filtering achieving EN 55022 Class B conducted emissions compliance

- X and Y capacitors sized balancing EMI attenuation against leakage current limits

- Common-mode choke design using high-permeability cores achieving adequate inductance

- Multi-stage filtering providing >40dB attenuation at switching frequencies

- PCB layout minimizing parasitic bypass paths maintaining filter effectiveness

- Component selection considering voltage ratings, temperature stability, and aging characteristics

Ensuring Safety Isolation and Compliance

Reinforced isolation between mains and user-accessible outputs prevents electric shock hazards meeting UL 60950, IEC 62368, or medical IEC 60601 standards requiring adequate creepage/clearance distances, validated transformer construction, and comprehensive protection circuits ensuring safe operation despite single-fault conditions.

APTPCB implements validated safety designs achieving international certifications.

Key Safety Requirements

Isolation Barrier Implementation

- Creepage distance (typically 6-8mm for reinforced isolation) maintaining surface separation with high-Tg PCB materials preventing tracking

- Clearance distance (typically 4-6mm) providing air gap preventing arc-over during transients

- PCB material CTI >175 resisting carbon tracking under contamination

- Transformer construction using triple-insulated wire or adequate primary-secondary spacing

- Hipot testing applying 3kV+ for 60 seconds validating dielectric strength

- Compliance testing per UL, VDE, TUV, CCC standards supporting global market access

Protection Circuit Integration

- Input overvoltage protection using MOVs clamping lightning and switching transients

- Output OVP preventing overvoltage from control circuit or component failures

- Overcurrent protection using foldback limiting or hiccup mode preventing thermal damage

- Short circuit protection immediately limiting or shutting down during output shorts

- Thermal protection monitoring temperatures triggering shutdown before component damage

- Touch current measurement validating leakage remains within safety limits

Optimizing Efficiency and Thermal Management

Modern AC-DC supplies target 85-92% efficiency meeting Energy Star, DOE Level VI, or ErP requirements minimizing no-load power <0.1-0.3W. Achieving efficiency targets requires topology optimization, synchronous rectification, and thermal management maintaining component temperatures within specifications preventing premature aging or failures.

APTPCB implements thermal designs ensuring reliable continuous operation.

Key Efficiency and Thermal Techniques

Topology and Control Optimization

- Flyback converters (5-150W) using quasi-resonant or frequency modulation improving light-load efficiency

- LLC resonant converters (>100W) achieving >92% efficiency through soft-switching

- Synchronous rectification replacing output diodes with MOSFETs improving efficiency 2-4%

- Digital control enabling adaptive operation and efficiency optimization across load ranges

- Component selection prioritizing low Rds(on) MOSFETs and low-loss magnetic materials

- Validation testing measuring efficiency at 25%, 50%, 75%, 100%, and no-load conditions

Thermal Management Implementation

- Heat sink design and integration for power semiconductors maintaining junction temperatures

- PCB copper distribution with flex PCB or heavy copper spreading heat from components

- Thermal via arrays transferring heat through PCB layers to opposite-side cooling

- Component placement considering airflow patterns in natural or forced convection

- Thermal simulation validating temperatures remain within component specifications

- Production testing measuring temperatures under rated load confirming thermal performance

Supporting Multiple Output Configurations

Many applications require multiple voltages: microcontrollers (3.3V, 5V), analog circuits (±12V), and loads (12V, 24V, 48V). Multi-output implementations use multiple secondary windings, post-regulators, or isolated modules balancing cost, efficiency, cross-regulation, and complexity for specific applications.

APTPCB manufactures multi-output power supplies with validated performance.

Key Multi-Output Implementation

Multiple Secondary Design

- Transformer with multiple secondaries providing isolated or semi-regulated outputs

- Primary-side control or secondary-side regulation affecting cross-regulation performance

- Individual rectification and filtering for each output optimizing performance

- Current sensing and protection preventing single output overload affecting others

- PCB layout accommodating multiple output sections with adequate spacing

- Testing validation confirming output regulation and cross-regulation specifications

Enabling Diverse Application Markets

AC-DC supplies serve consumer electronics (chargers, adapters), industrial equipment (PLCs, motor drives), medical devices (patient monitoring), and telecommunications (base stations) requiring application-specific optimizations in certifications, efficiency, environmental ratings, and features.

APTPCB provides flexible manufacturing supporting diverse requirements.

Key Market Requirements

Consumer Electronics

- Compact size and cost optimization for competitive markets

- Energy efficiency (DOE Level VI, ErP) minimizing standby power

- Fast charging protocols (USB-PD, Quick Charge) for mobile devices

- Global safety certifications (UL, CE, CCC, PSE) enabling worldwide sales

- High-volume manufacturing achieving consumer pricing targets

Industrial and Medical

- Rugged construction surviving harsh environments (-40 to +70°C)

- Medical isolation (IEC 60601) and low leakage current for patient safety

- DIN rail or chassis mounting for industrial enclosures

- High reliability (>100,000 hour MTBF) supporting minimal maintenance

- Industry-specific certifications (UL508, UL60601, IEC 61010)

Through application-optimized designs, flexible manufacturing, and comprehensive certification support, APTPCB enables AC-DC power supply manufacturers serving diverse global markets.

Delivering Cost-Effective Production

Successful AC-DC supply manufacturing balances quality, reliability, and cost meeting market expectations. Cost optimization requires DFM collaboration, process efficiency, supply chain management, and continuous improvement reducing costs without compromising performance.

APTPCB delivers cost-effective manufacturing through optimized processes.

Key Cost Strategies

Manufacturing Optimization

- DFM review identifying cost reduction opportunities through standardization

- Automated assembly and testing maximizing throughput and consistency

- Process optimization eliminating waste and reducing cycle times

- Strategic component sourcing achieving competitive pricing and availability

- Volume manufacturing capability supporting economies of scale

- Quality systems preventing defects and rework costs

Through comprehensive optimization and efficient processes coordinated with rigid-flex PCB capabilities when needed, APTPCB enables competitive AC-DC power supply manufacturing supporting successful products worldwide.