High-Speed Loss Budget

Megtron 6/7/U keep insertion loss within 0.3–0.5 dB/in at 28–56 GHz, critical for 56/112 G lanes.

- Df as low as 0.0010 (Megtron U)

- Spread-glass mitigates weave skew

- Supports long backplanes and AI fabrics

Materials

We build Megtron 4/6/7/U stacks for AI accelerators, PCIe Gen5/Gen6 cards, and 56/112 Gbps backplanes. The stack notes, glass mapping, and loss-control data come from Panasonic datasheets plus RayPCB/RayMing deployments, allowing us to hit COM budgets and warpage targets consistently.

Megtron 6/7/U keep insertion loss within 0.3–0.5 dB/in at 28–56 GHz, critical for 56/112 G lanes.

Tg ≥200 °C with 45–55 ppm/°C Z-axis CTE keeps sequential lam builds stable through multiple reflows.

Material constants align with Panasonic data; we ship Ra/Rz, TDR, and COM overlays for each lot.

| Series | Dk / Df @10 GHz | Use Case |

|---|---|---|

| Megtron 4 | Dk 3.6 / Df 0.008 | Enhanced FR-4 replacement for 25–28 G |

| Megtron 6 | Dk 3.4 / Df 0.002 | 56 G SerDes, PCIe Gen5 backplanes |

| Megtron 7 | Dk 3.3 / Df 0.0014 | 112 G PAM4 cards with low loss |

| Megtron U | Dk 3.2 / Df 0.0010 | Ultra-low loss for long-reach AI fabrics |

| Megtron 8 / GX | Dk 3.25 / Df 0.0011 | Co-extruded low-loss options (on request) |

| Material / Thickness | Dielectric Constant | Dissipation Factor | Notes |

|---|---|---|---|

| Megtron 6 (0.010 in) | 3.40 ±0.05 | 0.0020 | Workhorse for 56 G backplanes |

| Megtron 7 (0.008 in) | 3.30 ±0.03 | 0.0014 | Spread-glass laminate |

| Megtron U (0.006 in) | 3.20 ±0.03 | 0.0010 | Ultra-low loss / optical modules |

| Megtron 4 (0.014 in) | 3.60 ±0.05 | 0.0080 | FR-4 drop-in for 10–25 G |

| Megtron 6 Prepreg R-5725 | 3.40 | 0.0025 | Pairs with stacked microvia builds |

Panasonic datasheet values mirrored via RayPCB archives; verify actual lots for solver entries.

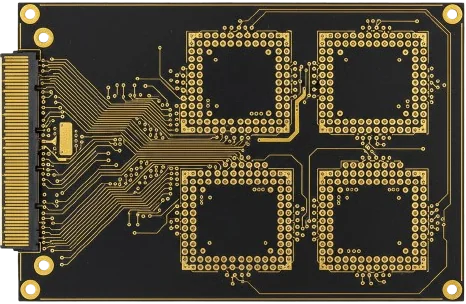

Differential stripline fabrics with VIPPO connectors and copper coins.

Mix of Megtron 7 signals and Megtron 6 planes for PCIe Gen6 cards.

Short-reach 112 G lane board with air cavity connectors.

All cores/prepregs baked at 120 °C and pressed with documented temperature/pressure ramps.

Stacked microvias qualified via IST/CAF, cross-sections, and plating thickness checks.

VLP/HVLP foil certs attached with Ra/Rz plus micro-etch SPC for solver inputs.

TDR, VNA, eye/COM analysis and optional crosstalk sweeps accompany shipments.

Megtron 7/6 mix with heavy copper rails for accelerator sleds.

Megtron 6 18–26 layer backplanes for 56 G/112 G fabrics.

Megtron 7/U cards with 3/3 mil lines and stacked microvias.

Questions we run through before freezing a Megtron program.

Loss budget, reach, and connector set drive Megtron 4 vs 6 vs 7/U choice.

Define stacked/staggered microvias, VIPPO, and coin locations early.

Agree on TDR, IL, COM, and ESS deliverables per build.

Yes. Megtron 4/6/7 cores and 6-series prepregs are stocked in common thicknesses; Megtron U or specialty glass styles can be expedited from Panasonic.

Foil certificates and profilometer measurements are attached to every traveler, and Huray coefficients are updated to match measured S-parameters.

TDR coupons, insertion loss sweeps, COM/eye templates (upon request), IST for microvias, and environmental/ESS logs for qualification lots.

Provide Megtron 6/7/U layer counts, lane speeds, and via strategy—we'll send glass/copper picks, press curves, and a build quote within one business day.