Wearables

Foldable display hinge

0.075 mm PI, copper coins, PSA stiffeners, and 20k-cycle bend testing for consumer hinge devices.

0.075 mm20k cyclesPSA stiffener

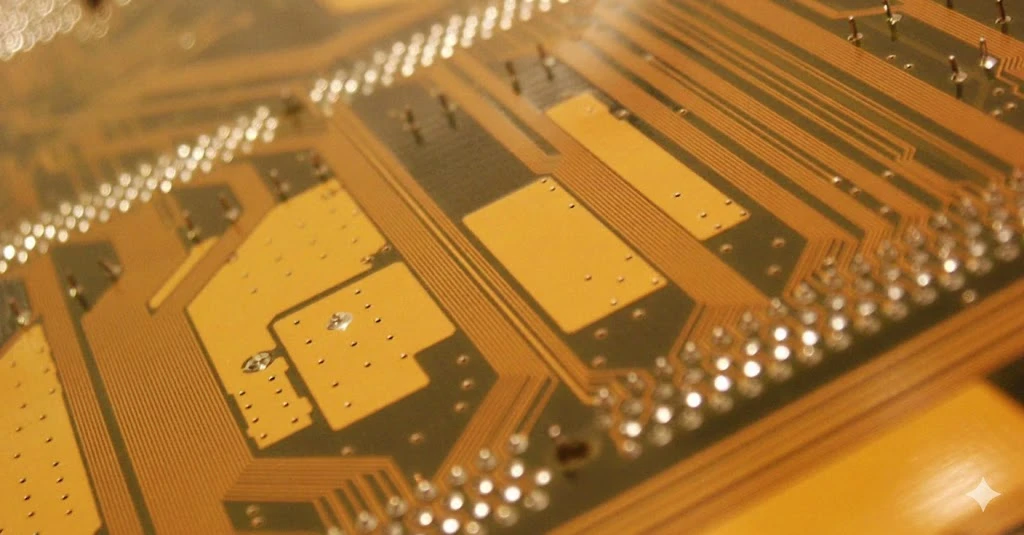

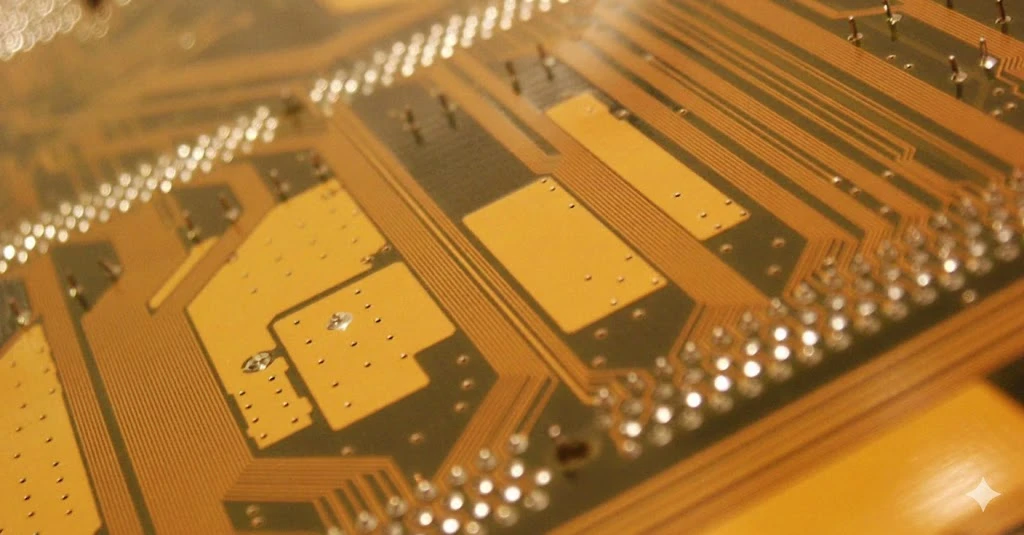

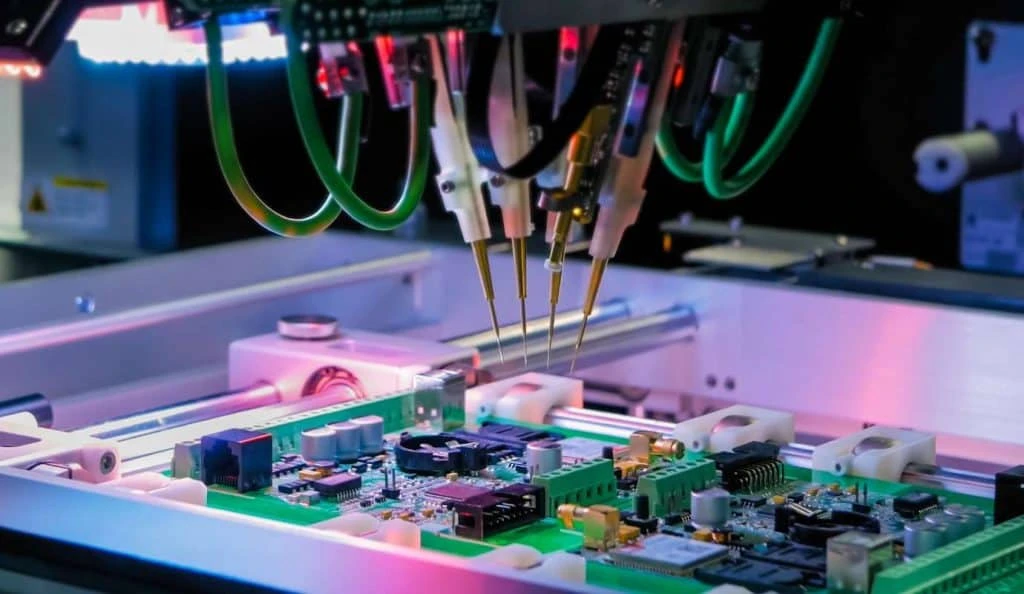

FLEX / RIGID-FLEX PCBA

Carrier tooling, stiffener bonding, laser coverlay, and staged handling purpose-built for flex boards, tails, and rigid-flex harnesses that must survive tight bends and connectors.

Lines, tooling, and inspection routines are configured around thin dielectrics and complex bend radii.

Laser-prepped openings and cameras verify copper exposure.

SMT heads, carriers, and reflow recipes mapped for flex films.

Mandrel and torsion rigs tied to SPC to validate every build.

FLEX COVERAGE

From stackup intake to carriers, stiffeners, SMT, and final test, every stage is anchored to reliability deliverables.

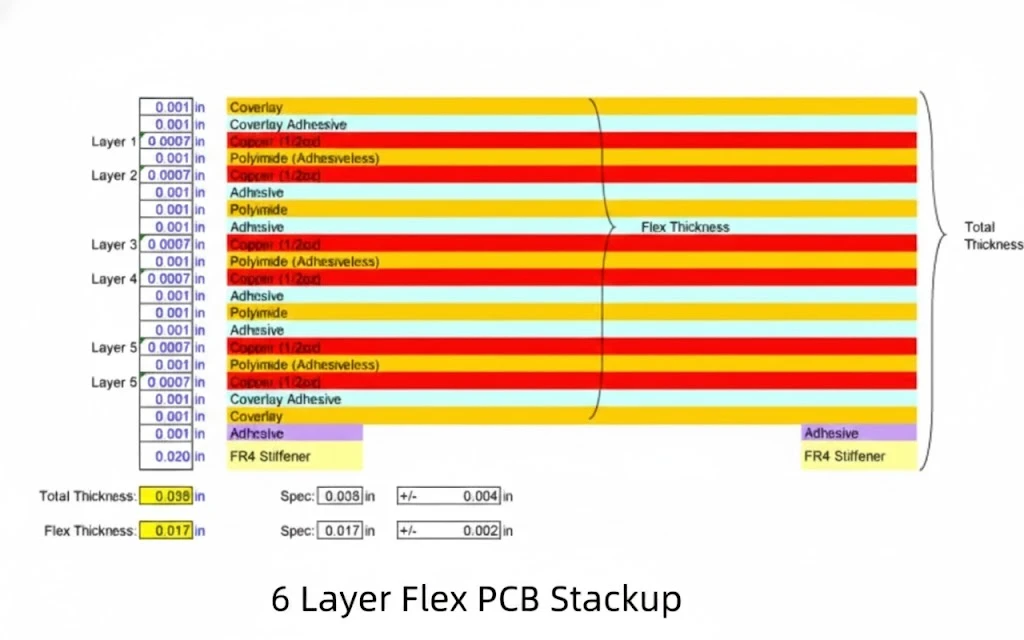

Stackup & stiffeners

Capture PI/LCP thickness, copper weights, PSA and FR-4 stiffener layouts.

Carrier & tooling

Vacuum, framed, and Kapton-backed pallets prevent distortion through print/reflow.

Assembly & handling

Low-tension peel, nitrogen reflow, selective solder, and hand ops with microscopes.

Reliability & test

AOI/X-ray plus bend, thermal shock, and continuity verification per tail.

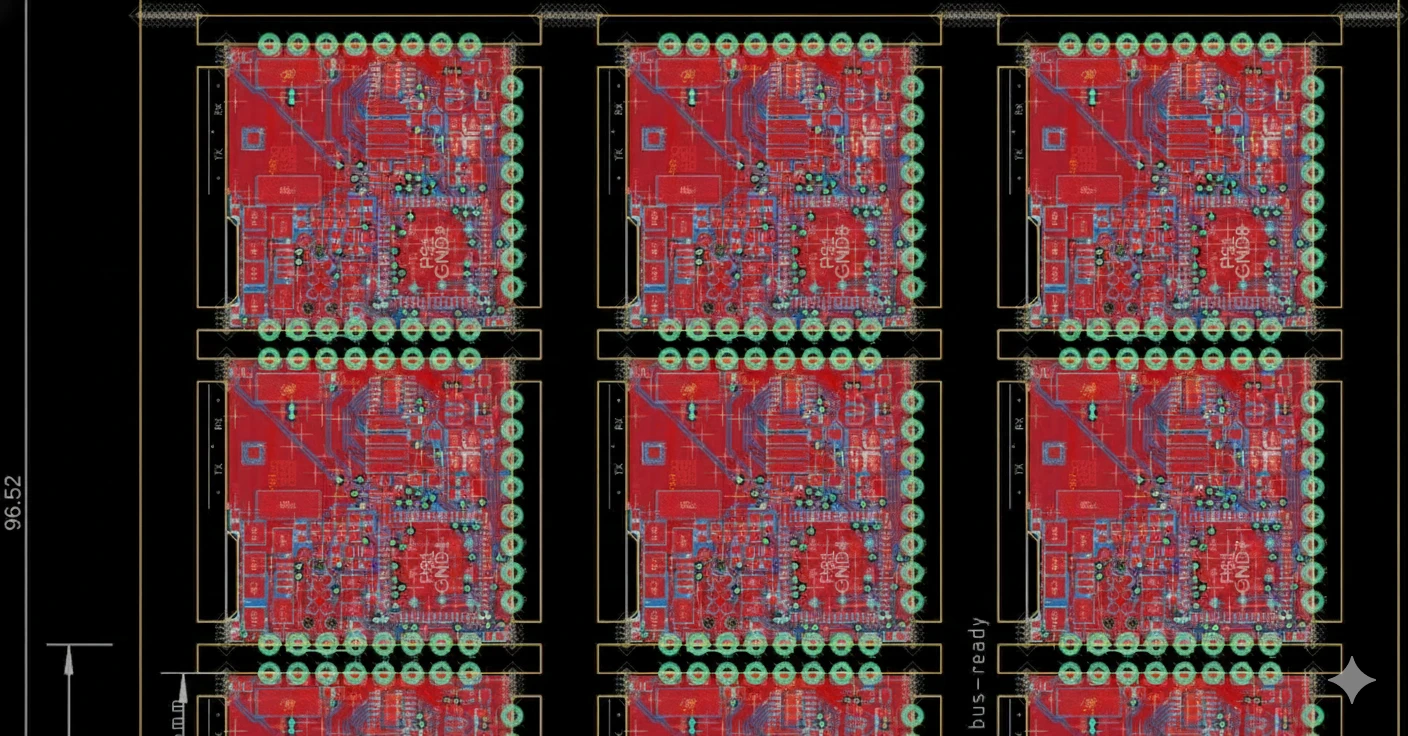

WORKFLOW

Each traveler ties stackup details, tooling, and verification checkpoints to the build.

Stackup intake

Review PI/LCP stackup, stiffener map, copper balance, and bend radii with engineering.

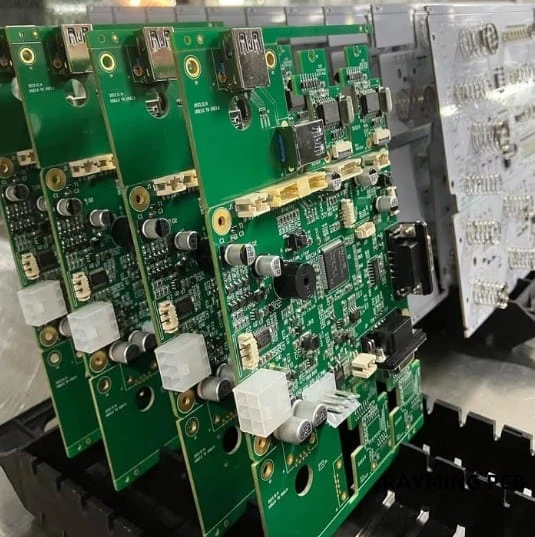

Tooling & carriers

Design vacuum plates, peel tabs, PSA/stiffener presses, and alignment pins.

Assembly & inspection

SMT/THT with flexible carriers, inline AOI, X-ray for BGA/buried joints, and 100% visual.

Reliability release

Mandrel bend, flex-to-install, and thermal cycling data logged before shipment.

PORTFOLIO

Wearables, radar harnesses, and medical imaging tails proven on flex-ready cells.

CAPABILITIES

Carrier-ready SMT, stiffener bonding, and verification kits specific to flex builds.

ESD flooring, MSD storage, low-humidity staging, and microscope workstations tuned for flex.

QUALITY

Handling, inspection, and reliability sign-offs aligned with flex-specific failure modes.

Antistatic trays, magnetic clamps, and microscope-assisted touch-up prevent creasing.

AOI with flex-specific rules plus X-ray for rigid transitions and hidden pads.

Mandrel cycling, flex-to-install, and thermal shock data appended to each C of C.

Foldable hinges, display interposers, haptics, and antenna tails.

LCP flex lines, phased array feeds, and rigid-flex controllers.

Sterilizable probe tails, catheter flex, and UDI-ready harnesses.

Robotic harnesses, sensor tails, and wear-resistant flex jumpers.

Everything you need to know about HDI PCB technology

Upload your stackup, Gerber, BOM/AVL, stiffener outline, and bend criteria to receive a detailed assembly and reliability plan.