Automotive

Automotive inverter

PPAP-level ICT, burn-in, and hi-pot reporting with CAR traceability.

ICTBurn-inHi-pot

INSPECTION • TEST • RELIABILITY

Inline SPI/AOI/AXI, flying probe, ICT/FCT, boundary-scan, burn-in, ESS, and cleanliness programs run under one traveler so supply chain, engineering, and quality share the same coverage data.

Layered inspection, electrical test, and reliability screens expose risk before boards ship.

Closed-loop printer feedback and 12 µm AOI.

Fixtures, limit files, and golden samples governed in MES.

Thermal, humidity, vibration, and hi-pot up to 5 kV.

COVERAGE

Inspection, test, and reliability teams share the same travelers, SPC dashboards, and corrective action loops so any deviation is captured in hours, not days.

Inspection layer

3D SPI, pre/post AOI, sample AXI, and post-wave AOI feed SPC dashboards.

Electrical test

Flying probe, ICT/FCT, boundary-scan, and firmware load under one plan.

Reliability & safety

Burn-in 12–48 h, ESS, hi-pot ≤5 kV, ground bond, and leakage tests.

Traceability & reporting

MES logging, cleanliness reports, CAR status, and waveform archives per lot.

PLAYBOOK

Coverage is planned alongside build so fixtures, screens, and reports are ready before the first lot.

DFT intake

Upload BOM, XY, netlists, schematics, and reliability specs for review.

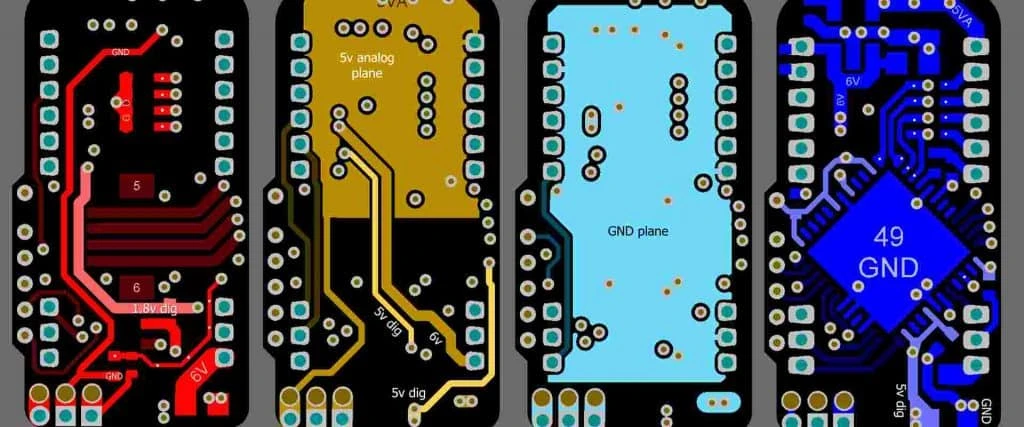

Coverage architecture

Map SPI/AOI, ICT/boundary-scan, FCT, and burn-in to CTQs.

Fixture & program build

ICT, flying probe, boundary-scan, firmware load, and burn-in recipes locked in MES.

Execute & monitor

Run inspection/test/ESS with SPC dashboards and live alerts on CpK, FPY, and trends.

Report & improve

Deliver FPY, CAR, cleanliness, hi-pot, and burn-in logs with corrective actions.

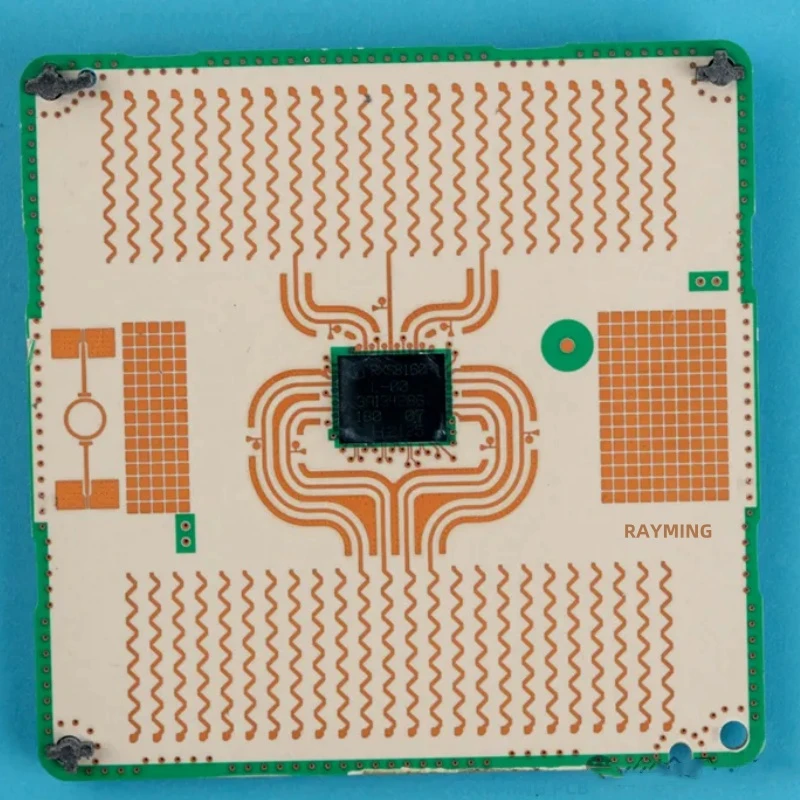

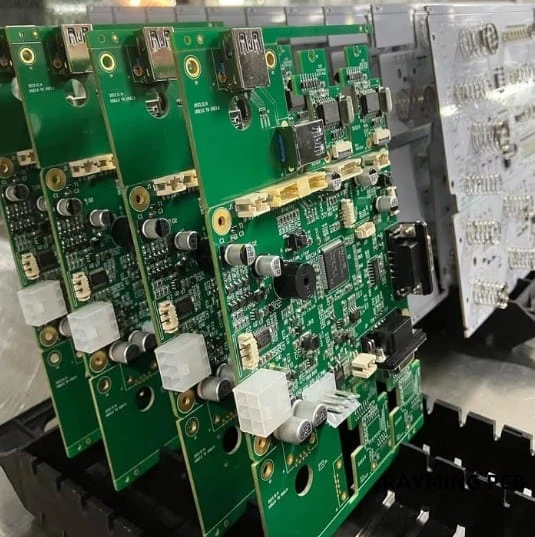

PORTFOLIO

Examples of inspection + electrical + reliability stacks we run each quarter.

CAPABILITIES

Equipment and processes tuned for proof of quality across regulated industries.

ESD and humidity-controlled labs with MES logging, fixture storage, and calibration programs.

QUALITY

Layered inspection + electrical + reliability data ensures no build ships without evidence.

3D SPI/AOI, sample AXI, and post-wave verification with SPC alerts.

Flying probe, ICT, boundary-scan, and FCT maintained with golden units and firmware control.

Burn-in/ESS, hi-pot, ground bond, and cleanliness logs attached to each traveler.

PPAP-ready FPY, ICT, burn-in, and hi-pot logs for ECU and inverter programs.

ISO 13485 cleanliness, traceability, and reliability evidence for Class II/III builds.

Rugged controllers verified with ESS, hi-pot, and conformal coat inspections.

Boundary-scan, FCT, RF calibration, and thermal screens for high-value boards.

Everything you need to know about HDI PCB technology

Upload files to receive a coverage proposal with inspection, ICT/FCT, burn-in, and reporting scope.