Firmware-Based Products

Microcontroller/SoC-based boards where firmware logic and control behavior are critical to product function.

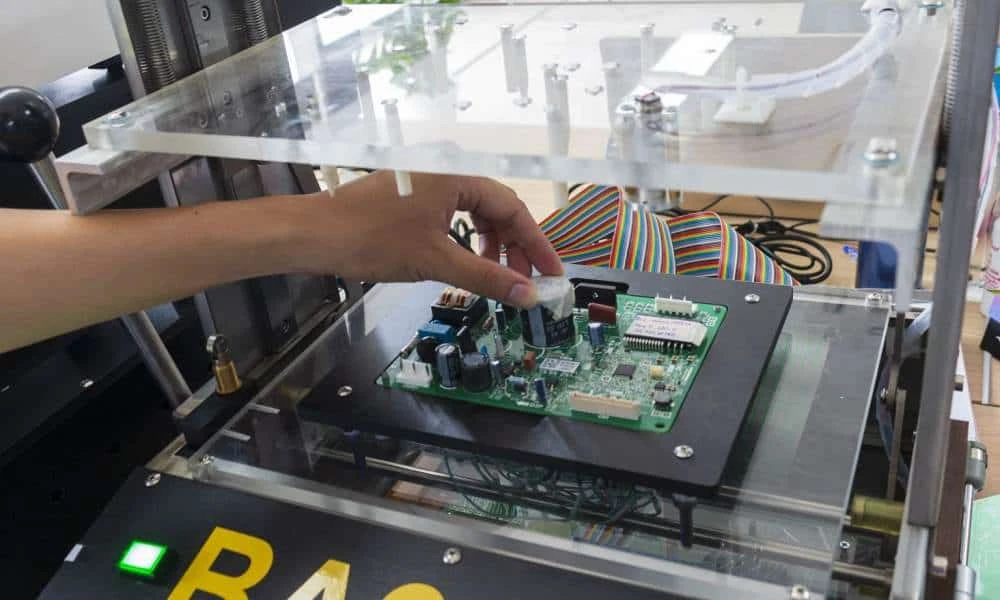

Functional Testing

PCBA Functional Test is the final and most critical step to make sure your assembled board really works as your product requires – not just that it powers on. APTPCB provides professional PCBA Functional Test services that verify the real operating behavior of your boards under power, with signals, loads, and communication interfaces connected.

Microcontroller/SoC-based boards where firmware logic and control behavior are critical to product function.

Boards with multiple communication interfaces like gateways, controllers, and IoT devices requiring comprehensive protocol validation.

Industrial control, power electronics, automotive-related, and certain medical/instrumentation areas where reliability is paramount.

Products where user experience and perceived quality are important, requiring comprehensive functional validation before delivery.

Contact APTPCB today to discuss your PCBA Functional Test requirements and build a test strategy that matches your product, volume, and reliability goals.