High-Tg CAM & Stackup Engineering

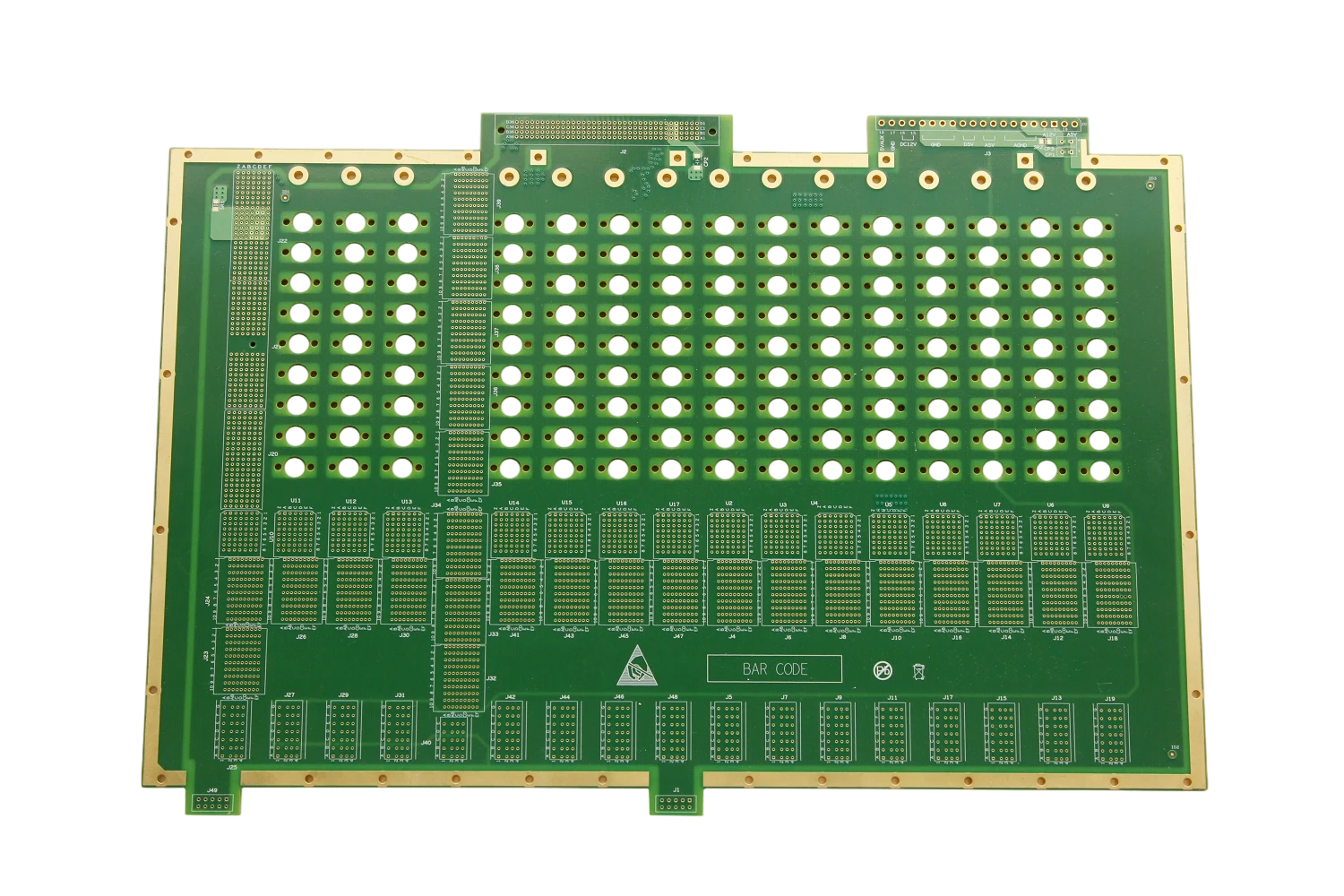

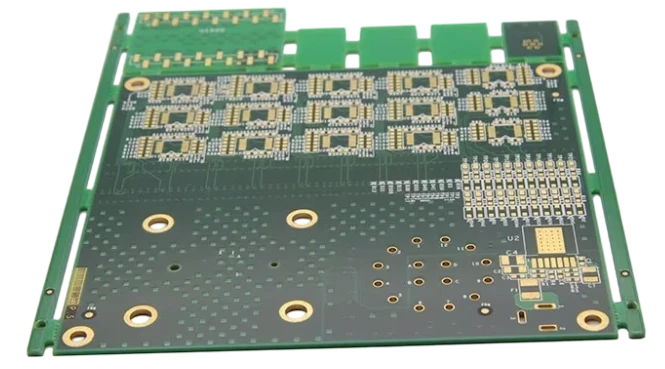

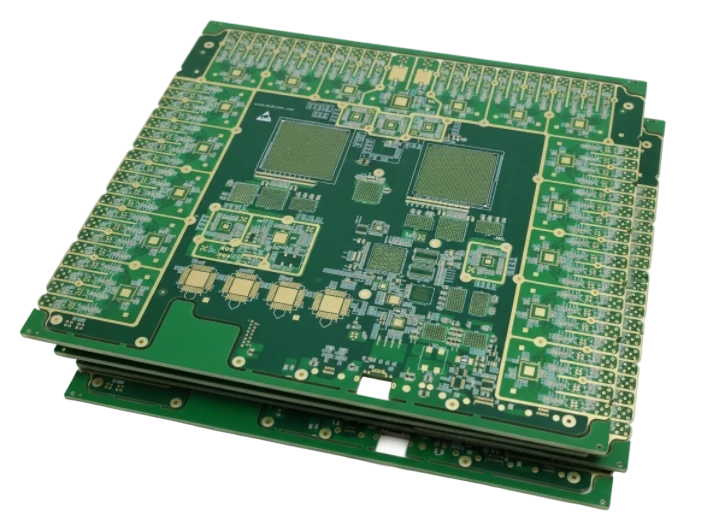

CAM engineers optimize copper balance, drill tolerances, and lamination cycles for high-Tg builds.

- Confirm Tg/Td specs per layer and acceptable substitutes.

- Define lamination cycles and cool-down rates to avoid resin stress.

- Plan CAF mitigation spacing and resin-filled via usage.

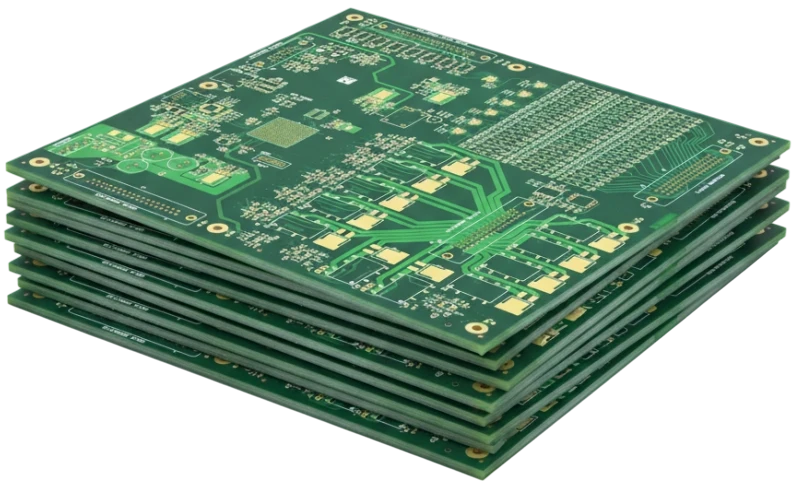

- Document bake requirements before imaging or assembly.

- Specify surface finish compatible with lead-free reflow and press-fit hardware.

- Provide coating/mask keep-outs for high-voltage areas.

- Release packaging instructions to protect boards after baking.