Early Defect Detection

Catch defects at the source—bare board or post-reflow—before they propagate downstream.

Quality Assurance

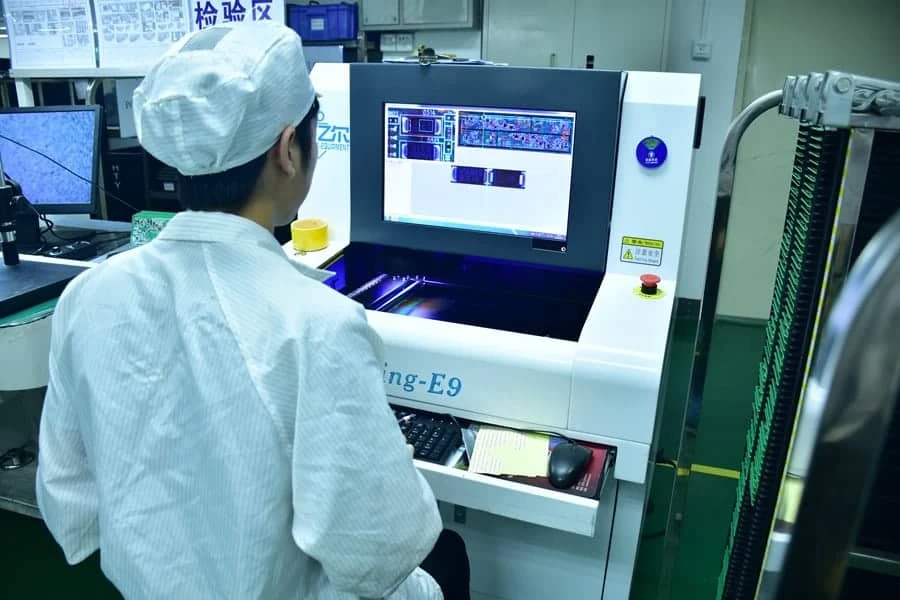

Automated Optical Inspection is critical for detecting defects on bare PCBs and assembled boards. APTPCB deploys advanced 2D/3D AOI technology throughout fabrication and assembly to catch issues early, reduce escapes, and ensure superior product quality.

Catch defects at the source—bare board or post-reflow—before they propagate downstream.

Systematic inspection keeps defect escapes below 100 ppm, protecting your reputation and reducing warranty costs.

Real-time process feedback and corrective actions enhance FPY and shorten debug cycles.

Comprehensive defect reports, Pareto charts, and trend analysis drive continuous process improvement.

Strategic deployment of 2D/3D AOI balances inspection rigor with production efficiency.

AOI seamlessly integrates with SPI, X-ray, ICT, and functional testing for comprehensive coverage.

Share your product specifications, volume requirements, and quality objectives. Our quality engineers will recommend the optimal AOI strategy—2D, 3D, inline, or standalone—tailored to your needs.