CAM Engineering Workflow — Converting Design Data into a Manufacturable HDI Process

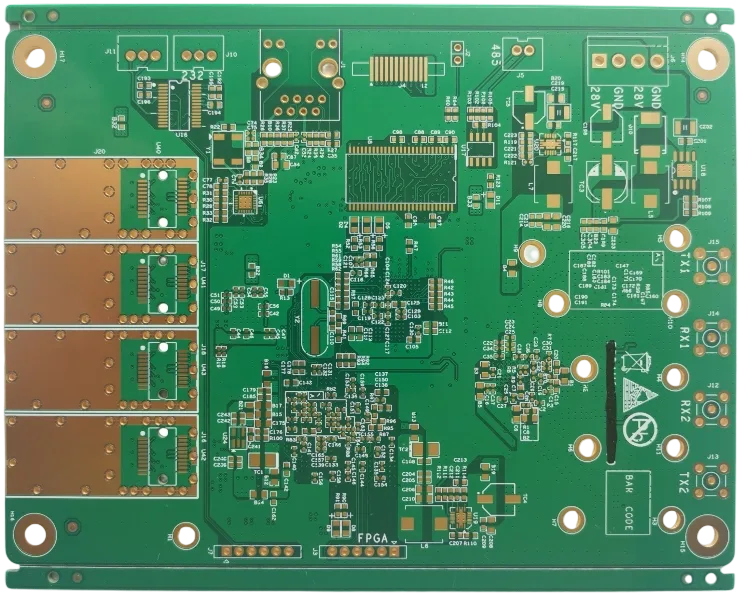

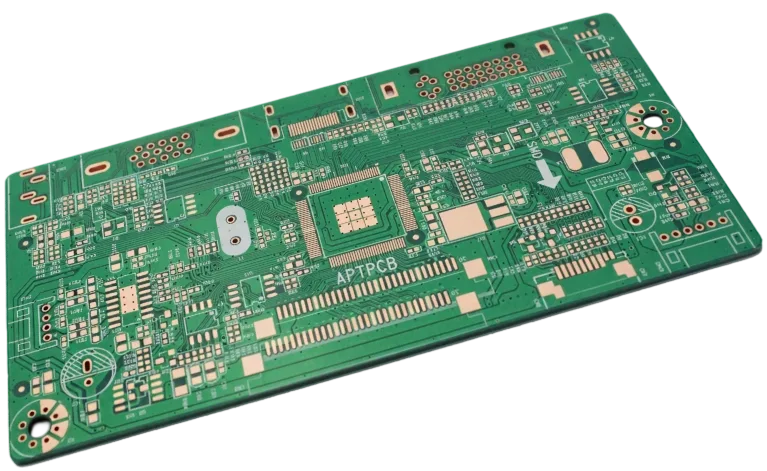

In the HDI PCB manufacturing process, the first essential phase is led by CAM engineers, who translate design intent into a precise, manufacturable production plan. After receiving Gerber or ODB++ data, they verify stack-up structures, microvia configurations, and impedance requirements. Through DFM analysis, drill programming, and fabrication note preparation, CAM engineers ensure every design feature aligns with production capabilities.

- Validate Gerber/ODB++ and confirm HDI layer stack-up, copper thickness, and prepreg configuration.

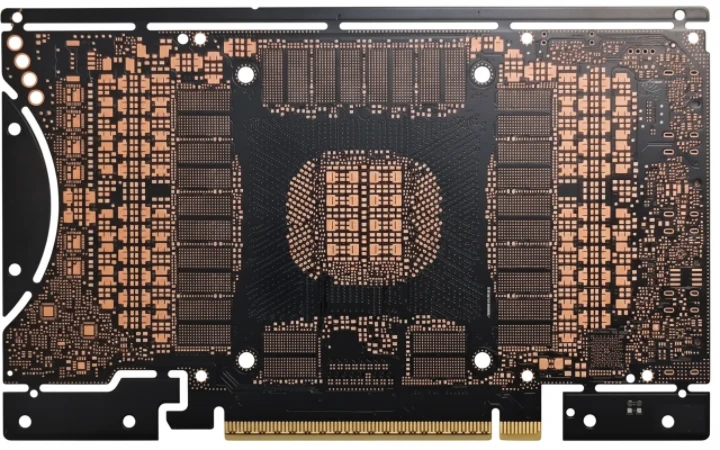

- Perform DFM/DFT checks — trace width and spacing, microvia pitch, annular ring size, and aspect ratio compliance.

- Generate precision drill and laser coordinate files (UV/CO₂) for microvias, blind vias, and buried vias.

- Annotate impedance-controlled nets, high-speed signal layers, and reference planes for fabrication accuracy.

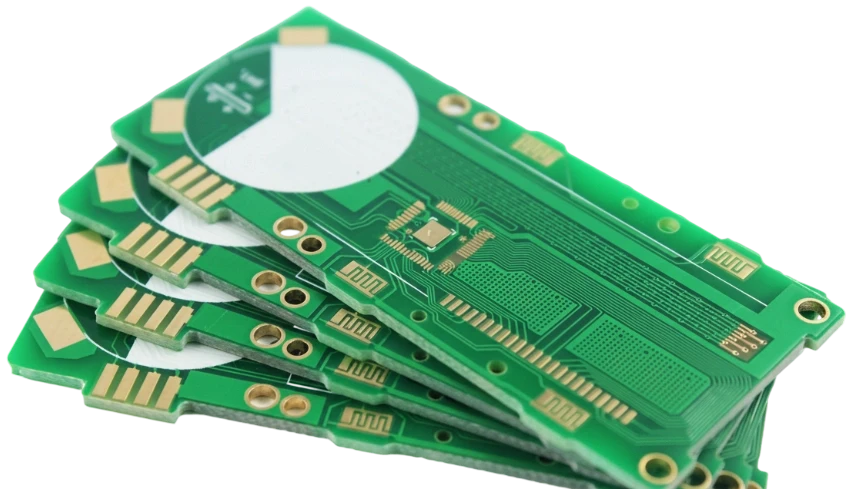

- Optimize panelization, fiducial placement, and tooling holes for stable lamination and imaging alignment.

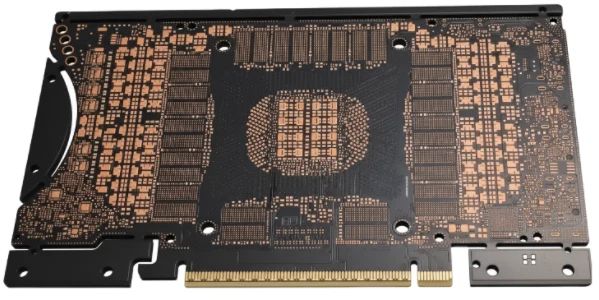

- Define fabrication notes including via-fill method, surface finish, and copper balancing requirements.

- Collaborate with production engineers for manufacturability review and process flow validation before release.