Automotive

Automotive control BOM

4k-line AVL with PPAP pack, LTB hedging, and AS6081 L2 screening.

PPAPLTBAS6081

CONTROLLED SUPPLY CHAIN

One supply-chain team audits BOMs within 24 hours, governs AVL and alternates, monitors lifecycle/PCN risk, executes AS6081 anti-counterfeit screening, and plans VMI/buffer stock. Every lot stays serialized in MES so engineering, purchasing, and QA share the same data.

Governed AVL, lifecycle alerts, and serialization prevent shortages and counter-measures from derailing builds.

Structure, alternates, compliance, and risk notes.

Qualified sources with quarterly refresh and audit trail.

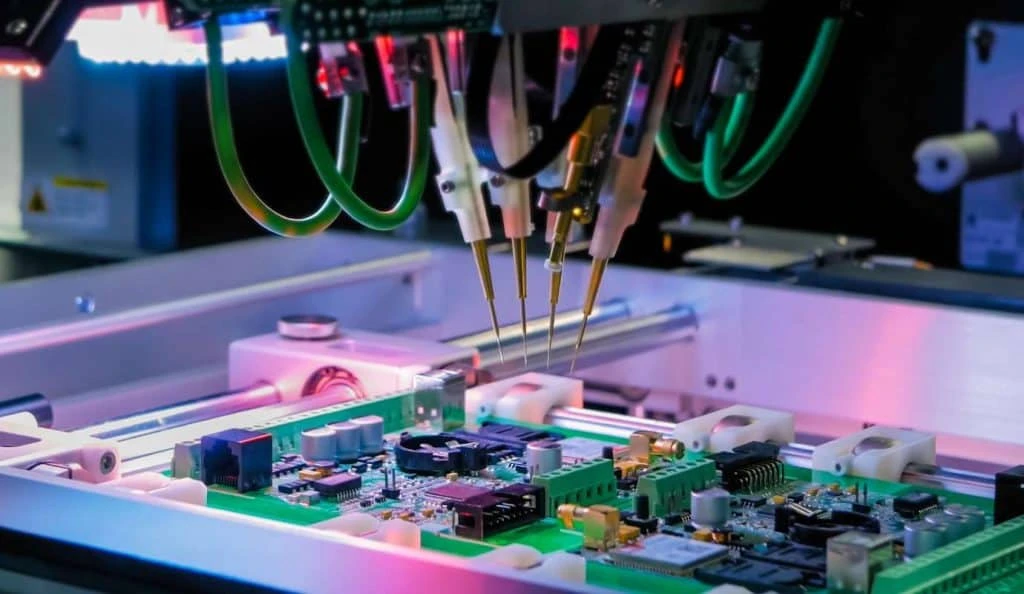

Visual, X-ray, XRF, decap, electrical + serialization.

COVERAGE

One accountable materials team owns BOM validation, alternates, sourcing, compliance, and logistics routines that feed production travelers.

BOM audit & structuring

Syntax and parametric checks, alternates, RoHS/REACH review, and AVL cross-matching in 24 hours.

AVL & lifecycle governance

Lifecycle scoring, PCN/EOL monitoring, LTB actions, and alternates matrix with engineering approvals.

Anti-counterfeit & incoming QC

AS6081 L1–3 flow with visual, X-ray, XRF, decap, electrical test, humidity control, and serialization.

Inventory & logistics

VMI/buffer programs, consignment, bonded inventory, ASN/EDI, and global fulfillment tied to MES lot IDs.

PLAYBOOK

Standard gates protect availability, authenticity, and compliance before kits hit the line.

Intake & audit

Submit BOM/AVL; receive alternates, lifecycle, and compliance actions inside 24 hours.

Govern & source

Approve alternates, lock AVL, hedge risks, and place buys through qualified suppliers.

Screen & serialize

AS6081 screening, MSD handling, photos, and serialization logged in MES.

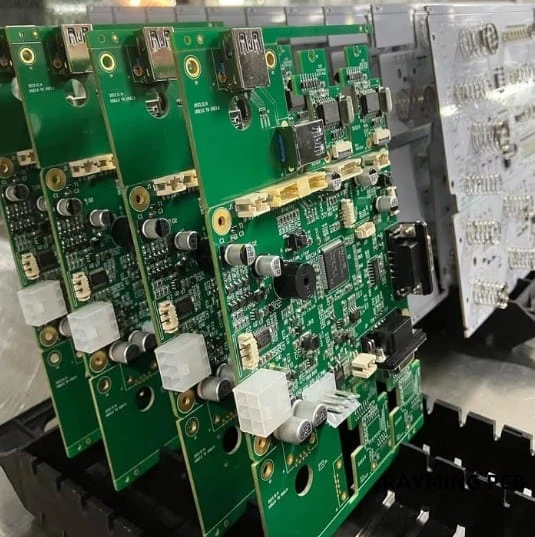

Kit & stage

Kitting with humidity control, labels, and traceability back to lot/date code.

Ship & report

ASN/EDI, PPV dashboards, and compliance packs accompany every shipment.

PROGRAMS

Examples of governed BOMs with lifecycle and anti-counterfeit controls applied.

CAPABILITIES

Governance, screening, and logistics tools that keep builds supplied and audit-ready.

Humidity-controlled kitting with barcode traceability and photos logged to MES.

QUALITY

Screening, compliance, and traceability routines keep assemblies safe from counterfeit or EOL risk.

Visual, X-ray, XRF, decap, electrical tests with retention samples.

Automated PCN/EOL alerts, LTB planning, and redesign advisories.

RoHS/REACH/UL CoCs, conflict mineral reporting, and documentation rooms.

PPAP-ready packs, controlled alternates, and AS6081 screening with genealogy.

ISO 13485 documentation, humidity control, UDI-ready serialization, and secure handling.

Hi-pot rated BOMs, coated/robust parts, and VMI buffers for long lifecycles.

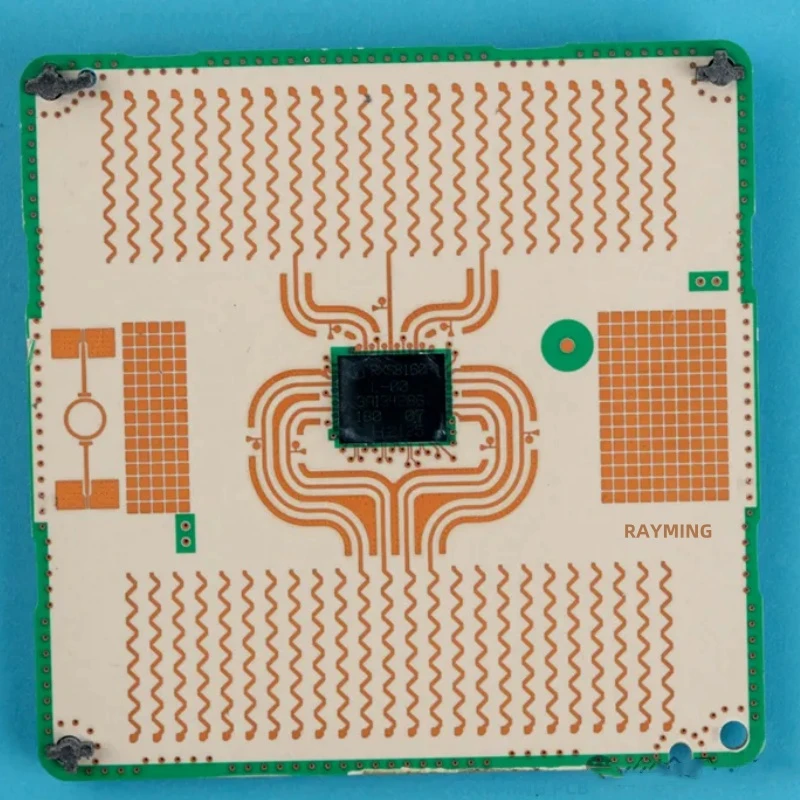

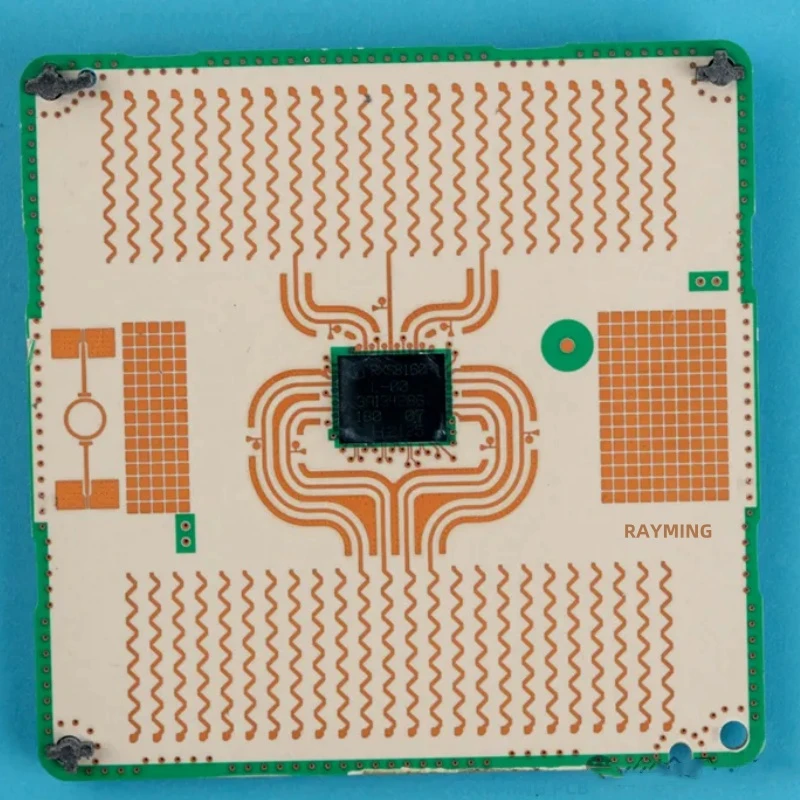

High-mix AVL with regional sourcing, RF parts governance, and retail-ready kitting.

Everything you need to know about HDI PCB technology

Upload your BOM to receive a structured review, alternates, and a sourcing/screening plan with timelines.