Industrial Control

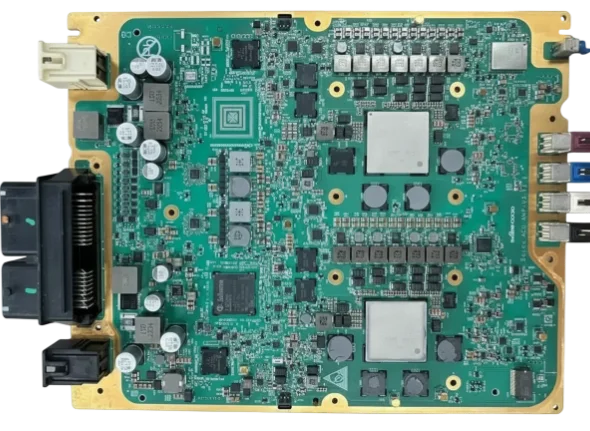

High-density industrial control boards

Multilayer boards with fine-pitch MCUs, FPGAs, and high pin-count connectors for automation and robotics.

8–12 layers0.3mm BGAMixed SMT/THT

COMPLETE TURNKEY SERVICES

End-to-end PCB assembly from design files to finished systems. We consolidate BOM/AVL management, component sourcing, SMT/THT, programming, functional test, and box-build under a single MES-tracked program team.

A turnkey model for hardware teams that need predictable delivery, clear data, and engineering-level conversations about manufacturing.

Engineering review and feedback instead of black-box pricing.

Prototype lots to volume runs handled with the same process discipline.

AOI, X-ray, and functional tests tuned to your risk and cost balance.

TURNKEY FLOW

One accountable program covering every essential step in electronics manufacturing, from bare boards to packaged systems.

PCB fabrication

Multilayer, HDI, and rigid-flex builds with controlled impedance and tailored stack-ups.

Component sourcing

BOM review, lifecycle checks, AVL alignment, and purchasing through qualified distributors.

SMT & THT assembly

High-speed placement, selective wave, and manual insertion for complex mixed-technology builds.

Testing & inspection

SPI, AOI, X-ray, ICT, boundary scan, and FCT configured to your coverage targets.

Box build & integration

Enclosures, harnessing, system-level assembly, and firmware loads for finished products.

Logistics & shipping

Protective packaging, serialization, documentation, and worldwide fulfillment.

TURNKEY FLOW

A clearly defined workflow from initial file submission to fully tested assemblies leaving the factory.

Submit files

Gerber/ODB++, BOM, placement and assembly notes.

Engineering review

DFM feedback and formal quotation.

PCB & materials

Board fabrication and full material preparation.

Assembly

SMT & THT with process monitoring.

Testing

AOI, X-ray and functional testing.

Shipping

Final inspection, packing and shipment.

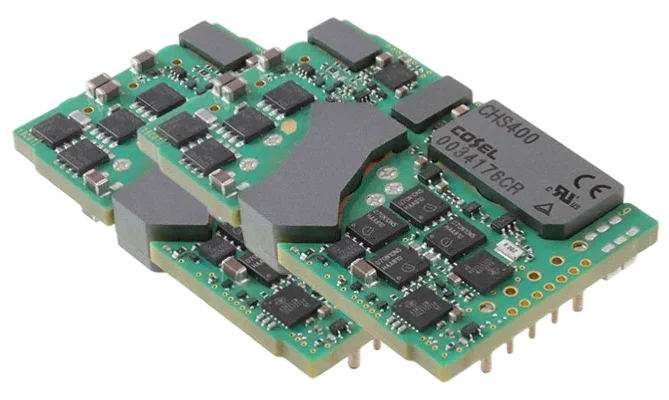

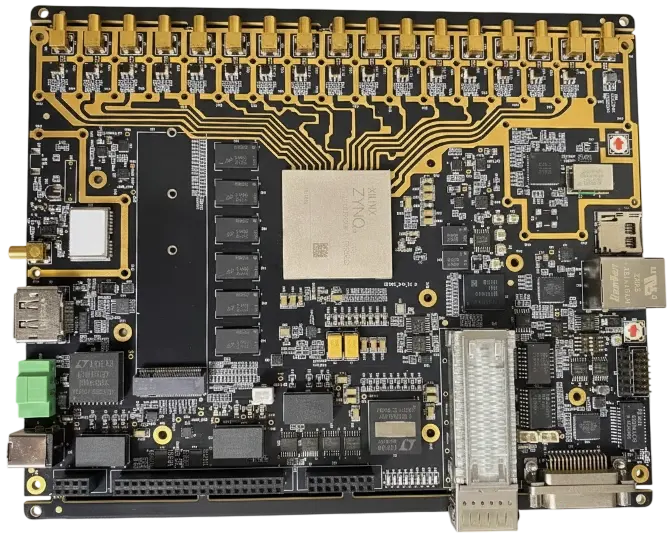

PORTFOLIO SHOWCASE

From high-density control boards to power electronics and RF modules – examples of turnkey PCBA projects we deliver regularly.

CAPABILITIES & EQUIPMENT

Advanced PCB and SMT capabilities combined with state-of-the-art equipment and controlled manufacturing environment.

Clean, clearly zoned SMT, THT, testing and packing areas with controlled material flow, ESD-safe workstations and monitored storage for moisture-sensitive devices.

QUALITY & CERTIFICATIONS

Process discipline, documented traceability and international standards at each stage of the turnkey flow.

PCBs and components are verified against specifications and approved vendor lists before production.

First article inspection, SPI, AOI and X-ray during assembly prevent defects and maintain yields.

Batch records and test reports support field performance tracking and analysis.

Turnkey assemblies for demanding environments, from factory floors to vehicles, clinics and connected devices.

Control modules, sensor interfaces and power boards for industrial equipment.

Electronics for vehicle control, lighting, charging and telematics systems.

PCBA for monitoring, diagnostic and laboratory devices with strict traceability.

High-speed boards for RF, backhaul and network infrastructure.

Compact, cost-optimized designs for smart home and connected products.

Everything you need to know about HDI PCB technology

Share your design files and requirements. Our engineers review, provide DFM feedback, and return a detailed quotation with lead time.