Thermal Stackup & CAM Engineering

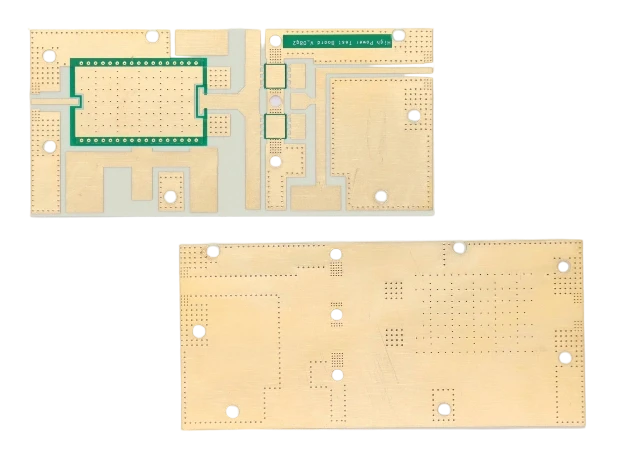

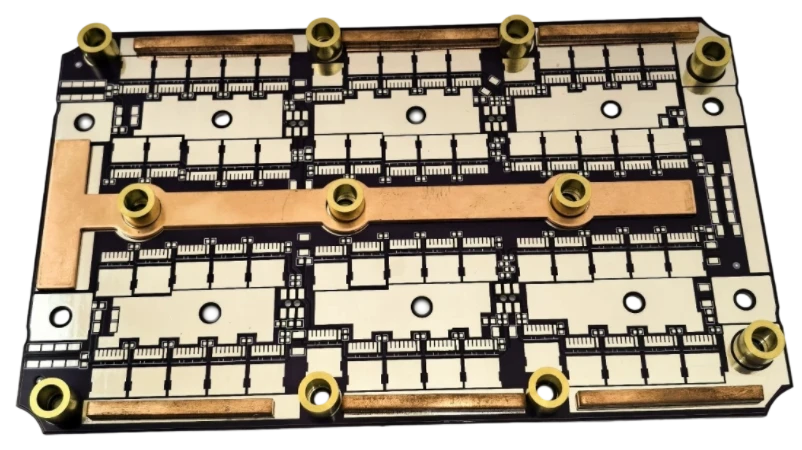

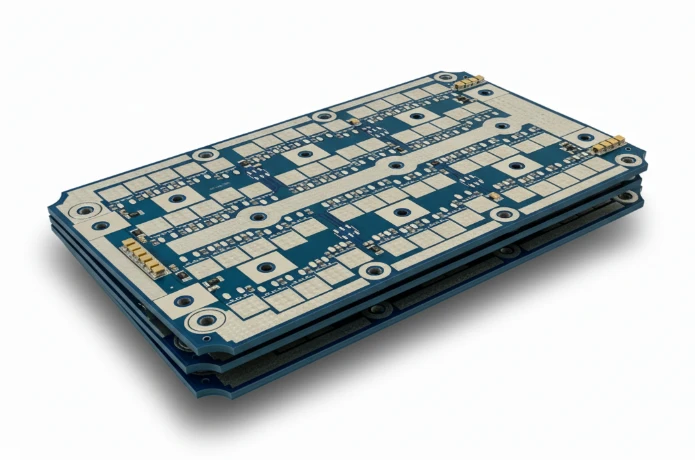

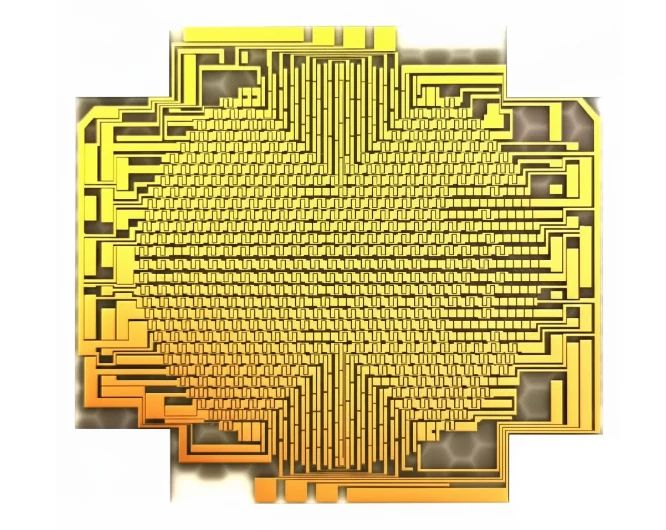

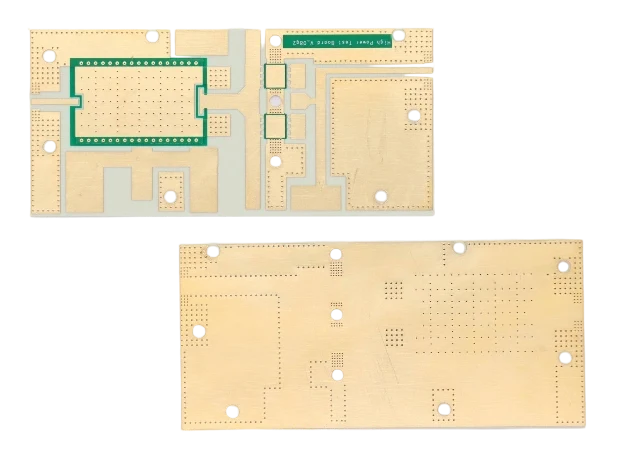

CAM teams align copper thickness, dielectric conductivity, and machining tolerances to your thermal budget.

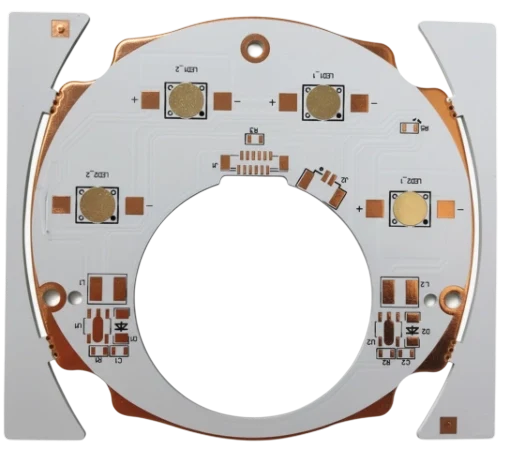

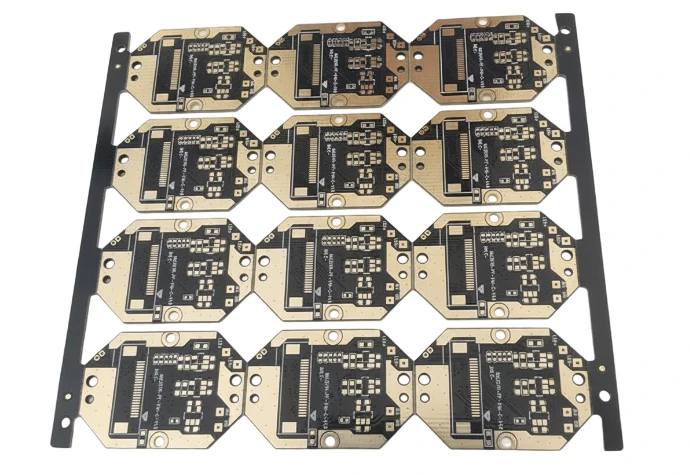

- Confirm conductivity, thickness, and CTE for dielectrics and substrates.

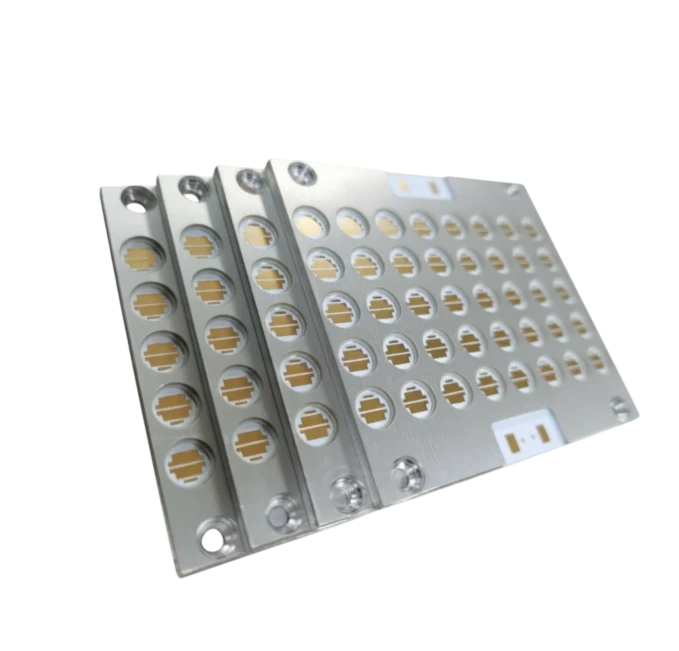

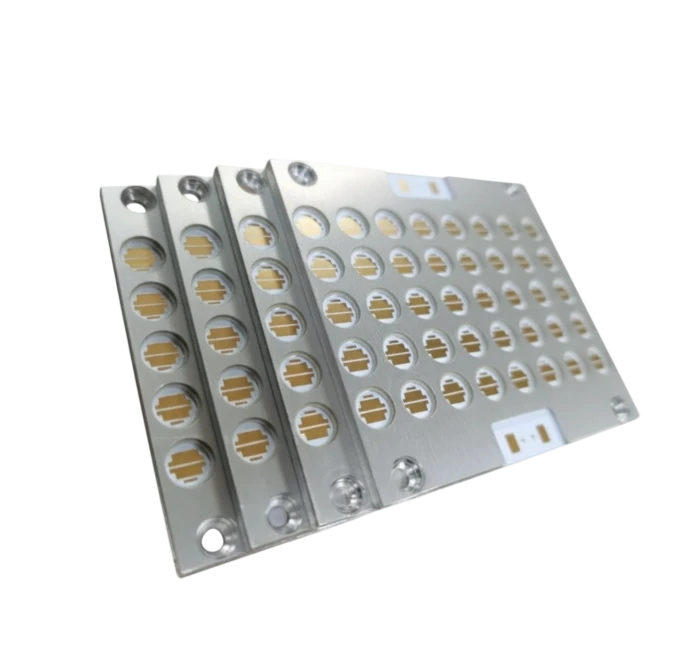

- Plan thermal via arrays, coin pockets, and alignment features.

- Define vacuum lamination or bonding recipes.

- Specify finishes compatible with LED reflectivity or power attachments.

- Document Hi-Pot spacing, creepage, and clearance.

- Provide handling instructions for bare metal bases and sharp edges.

- Release packaging notes to prevent oxidation and scratching.