Early and Precise Defect Detection

Identifying defects early in the production cycle, before they become more expensive to fix, with precise fault location.

Electrical Testing

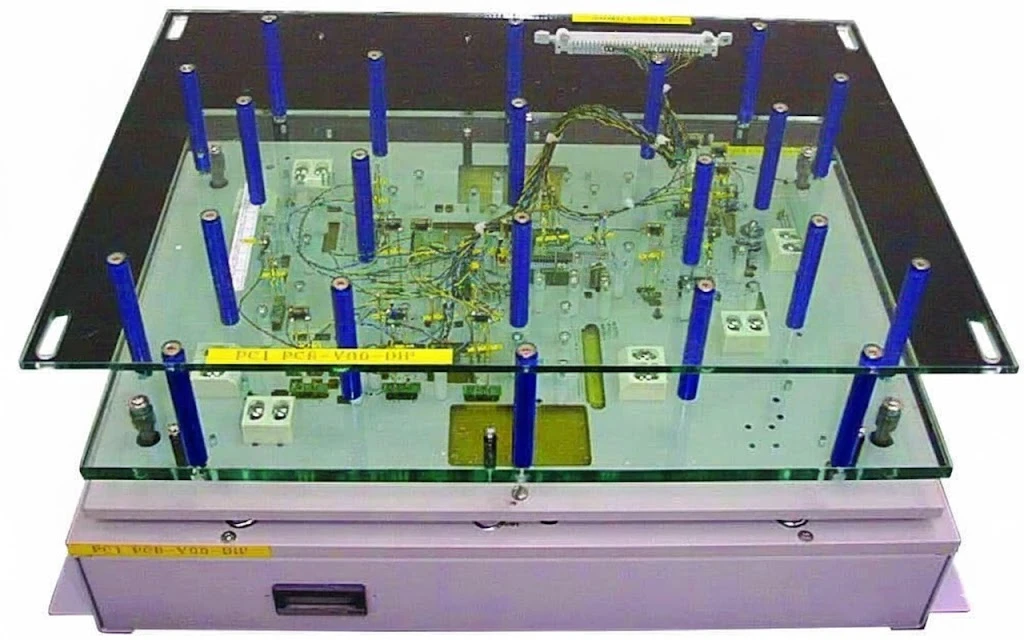

In-Circuit Test (ICT) is a powerful, automated testing method used to verify the electrical performance and integrity of individual components and their interconnections on a fully assembled Printed Circuit Board. APTPCB provides comprehensive ICT services with custom bed-of-nails fixtures, boundary-scan integration, and detailed defect analysis.

Our ICT systems utilize a custom-built test fixture (often referred to as a 'bed-of-nails' fixture), which consists of an array of spring-loaded pins precisely aligned to contact specific test points (nodes) on the PCBA. During the test, the ICT machine applies controlled electrical signals to these nodes and measures the responses, comparing them against pre-programmed expected values defined in the test program.

Identifying defects early in the production cycle, before they become more expensive to fix, with precise fault location.

Electrical verification of virtually every accessible component on the PCBA, ensuring values, orientations, and connections are correct.

Catching defects at the manufacturing stage minimizes costly rework or scrapping of entire assemblies later.

Ensuring only electrically sound PCBAs proceed to functional testing, leading to higher quality and enhanced reliability.

Automated test sequences running in mere seconds make ICT ideal for testing large volumes without sacrificing accuracy.

ICT is an integral part of APTPCB's comprehensive Quality Management System with traceable test results.

Contact APTPCB today to discuss your PCBA testing requirements and learn how our PCBA testing services can enhance the quality and reliability of your electronic products.