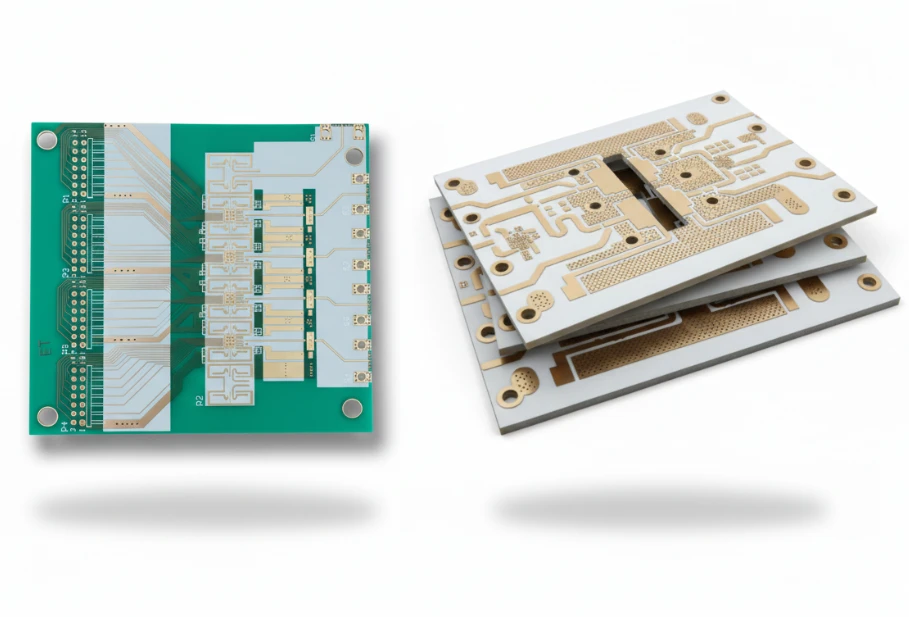

Microwave Stackup Engineering

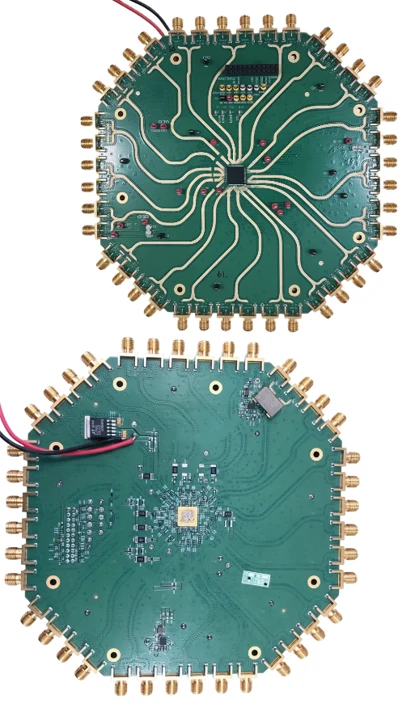

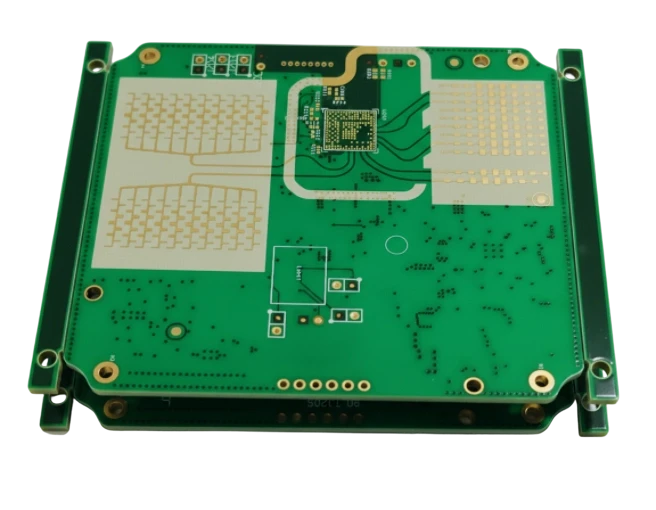

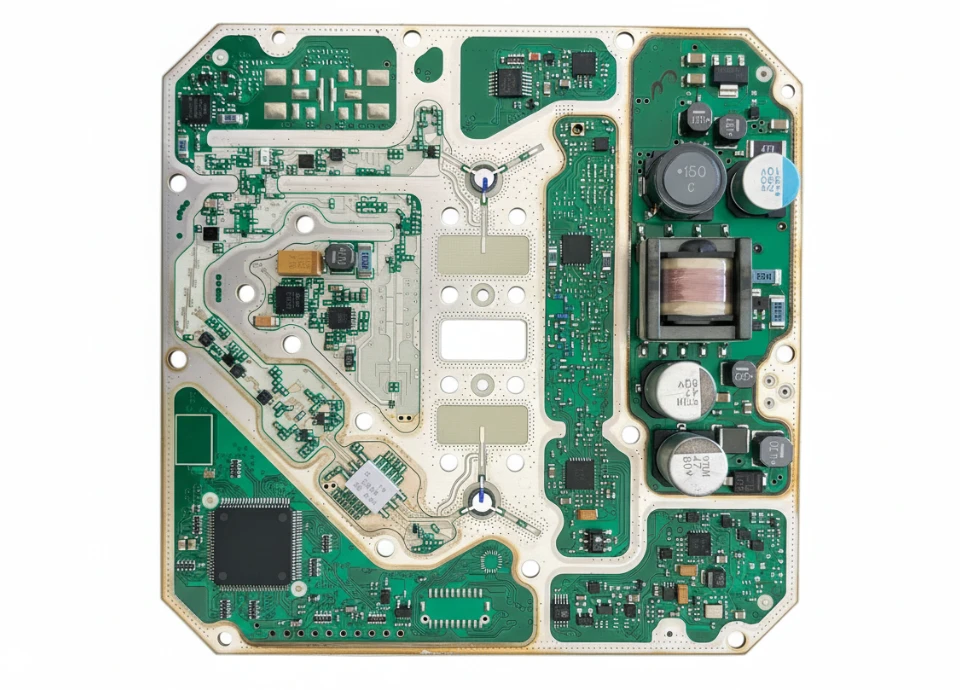

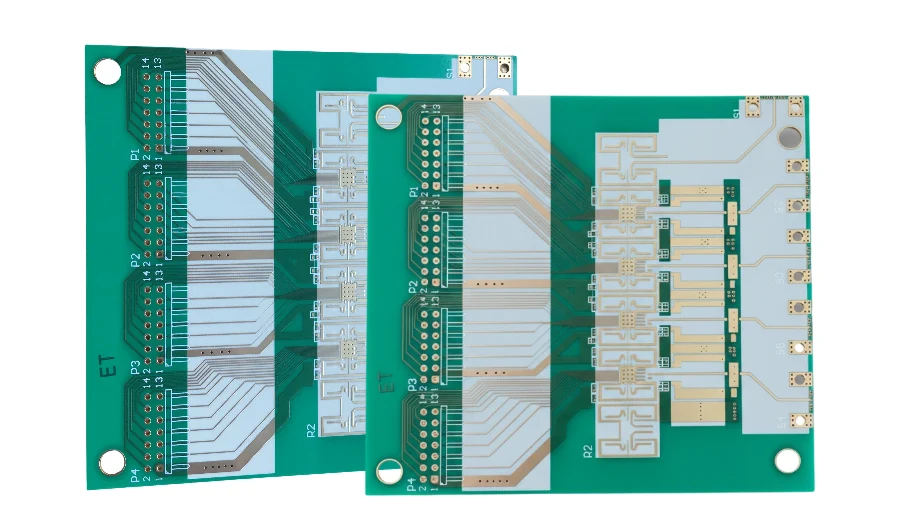

CAM + RF engineers guide stackups, cavity design, and impedance models.

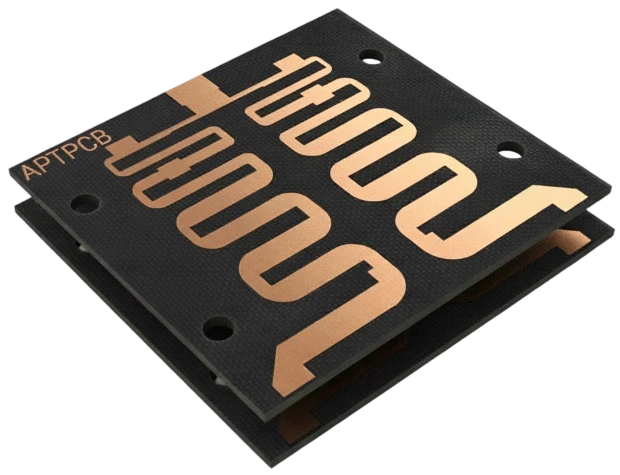

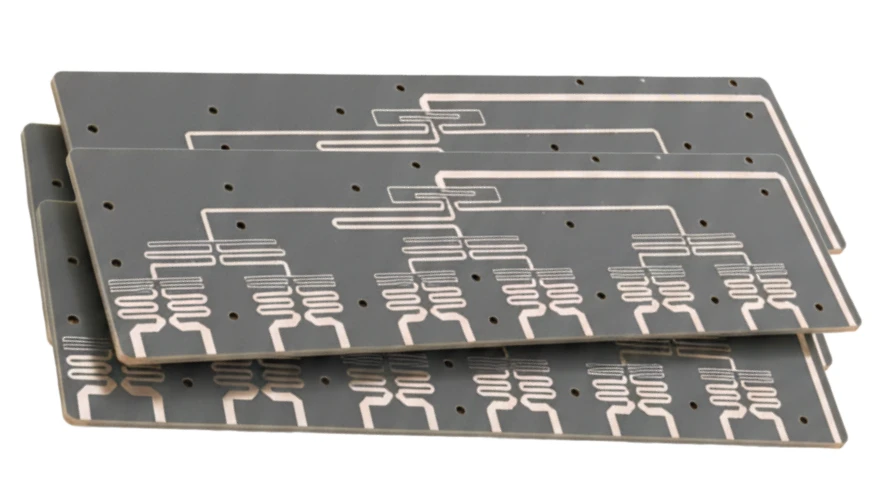

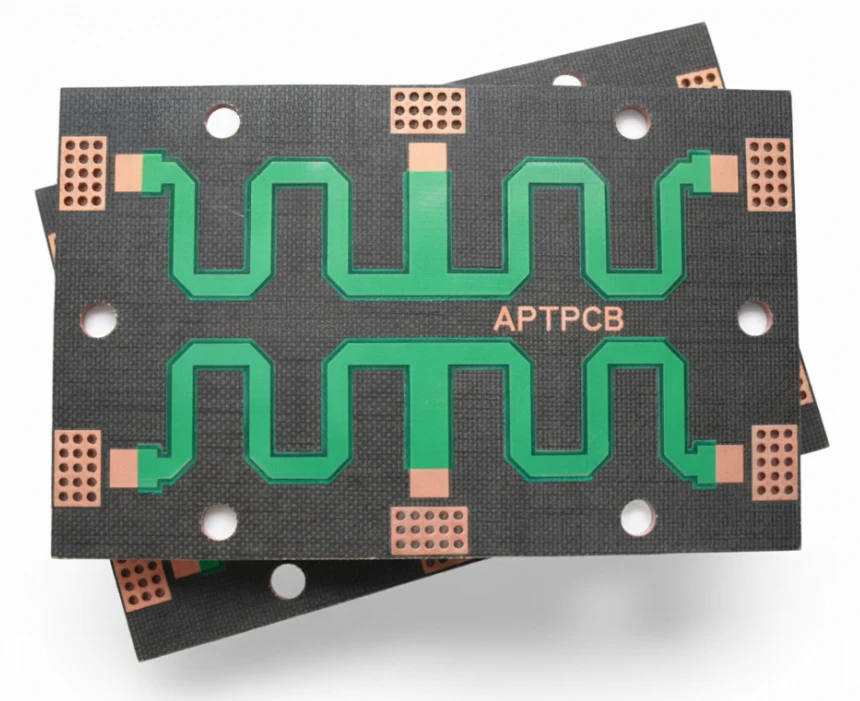

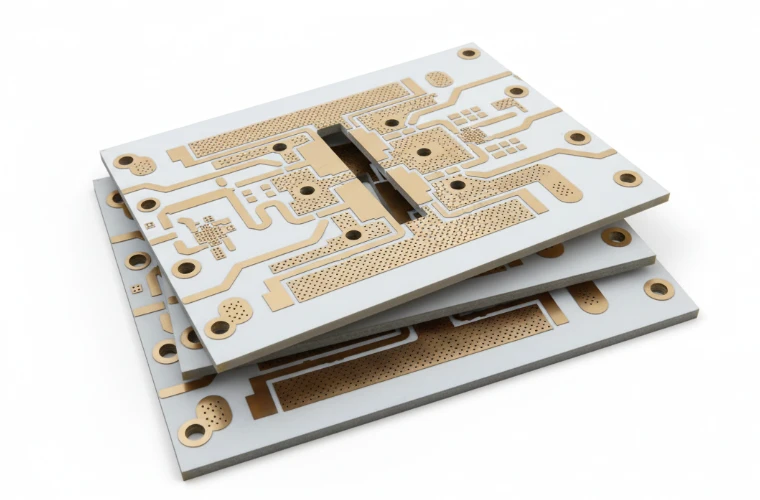

- Confirm laminates and acceptable alternates.

- Define cavity routing and plating.

- Plan impedance coupons and VNA fixtures.

- Specify finishes and coating keep-outs.

- Document handling for PTFE/ceramic.