Parallel DFM + kit prep

DFM reviews, PFMEA/control plan, and kit validation run the moment data lands so we release SMT in <24 h.

DFMPFMEA

DFX-FIRST NPI

NPI engineers, expedited SMT lines, and quick-turn fixtures let us move from DFM to assembled units in 48–72 hours when needed.

Dedicated SMT lines and engineers keep prototypes moving fast.

Parallel DFM + kit prep + SMT on expedited lines.

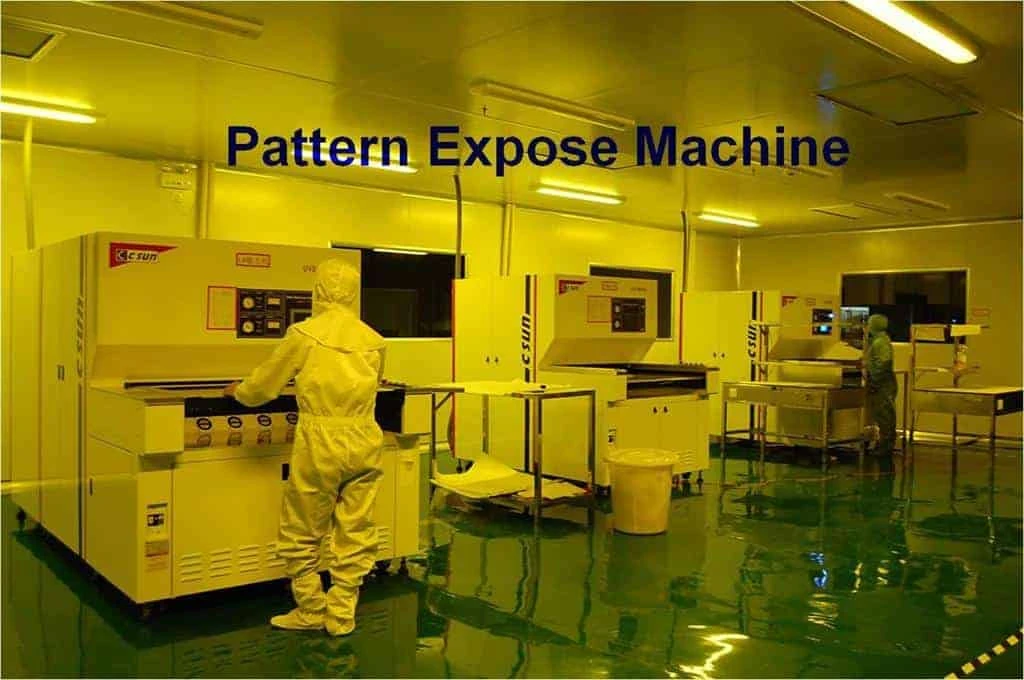

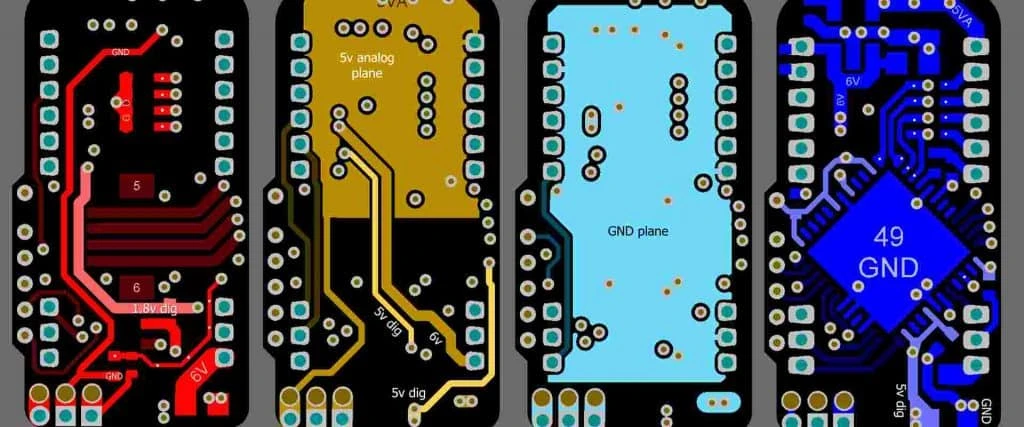

Gerber/ODB++ checks, PFMEA/control plan approval.

NPI traveler, photos, AOI/SPI logs packaged per lot.

NPI PROGRAM

Reserved NPI lines, BOM kitting, and DFM sign-off ensure prototypes are built correctly even on 48–72 h schedules.

DFM & kit readiness

Gerber/ODB++ ingest, stack-up/impedance checks, kit validation, and risk reviews within 24 h.

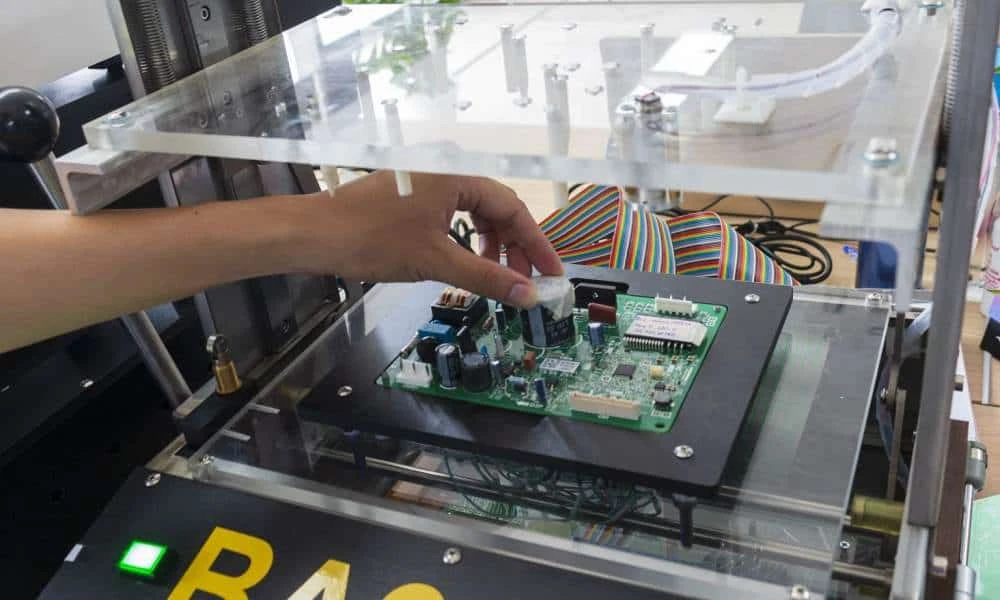

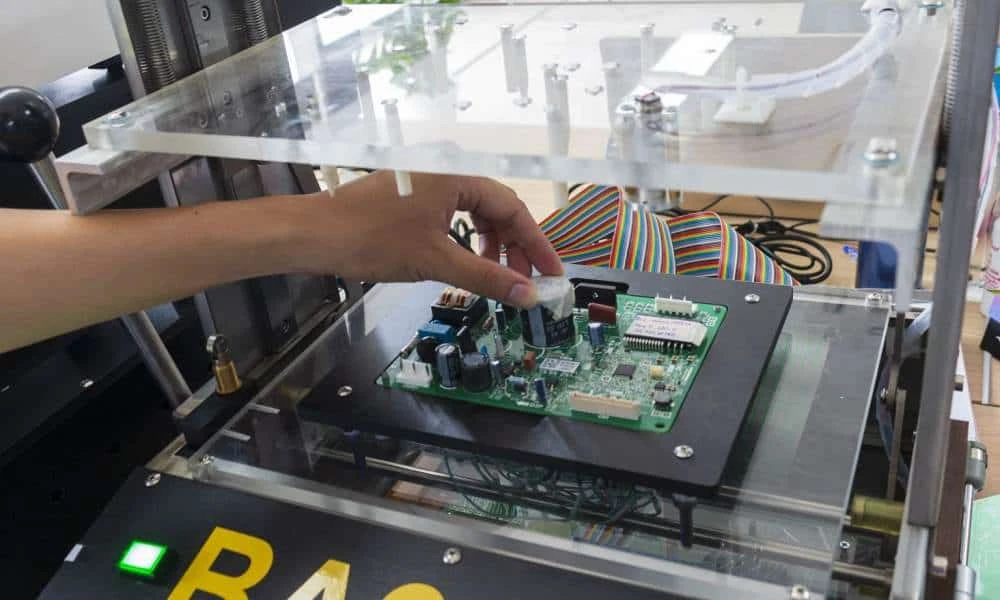

Dedicated SMT lines

Expedited SMT/Selective soldering with inline SPC, AOI, and NPI engineers on the floor.

Proof packages

AOI/SPI reports, photos, trace labels, and action logs delivered with the build.

PLAYBOOK

Clear gates keep every revision aligned with the data your ramp team needs later.

Submit package

Gerber/ODB++, BOM, XY, test intent, risk notes.

DFX + quote

24-hour feedback covering stackup, panel, stencil, access, and AVL health.

Build & inspect

Dedicated NPI lanes run SPI/AOI/X-ray/FAI with ECO-aware changeovers.

Test & program

Flying probe or ICT/FCT plus firmware loading and boundary-scan.

Pilot handoff

Run-at-rate option with golden samples, travelers, and FPY/FAI data.

QUICK-TURN SNAPSHOTS

Three pillars keep NPI builds fast and visible.

CAPABILITIES

Process windows tuned for prototypes, ECO-heavy cycles, and small-batch pilots.

Dedicated NPI cells with MSD controls, offline kitting, and ECO controls keep each revision clean.

QUALITY

Evidence-first QA so EVT/DVT findings survive ECOs and transfer to ramp.

Stackup, stencil, and access reviews with FAI photos and dimensional checks on every first article.

100% SPI/AOI with targeted X-ray; MSD baking and nitrogen profiles for fine-pitch parts.

Flying probe or ICT/FCT plans, boundary-scan, and firmware version control captured in travelers.

ISO 13485 builds with cleanliness checks, UDI-ready serialization, and secure file handling.

Conformal coat options, hi-pot, and firmware load for rugged controllers.

RF calibration support, boundary-scan, and regional packaging for pilots.

High-layer boards with BGA/CSP, thermal interface prep, and functional validation.

Everything you need to know about HDI PCB technology

Upload your package to get a DFX-backed quote and build window in under 24 hours.