MCPCB CAM & Thermal Engineering

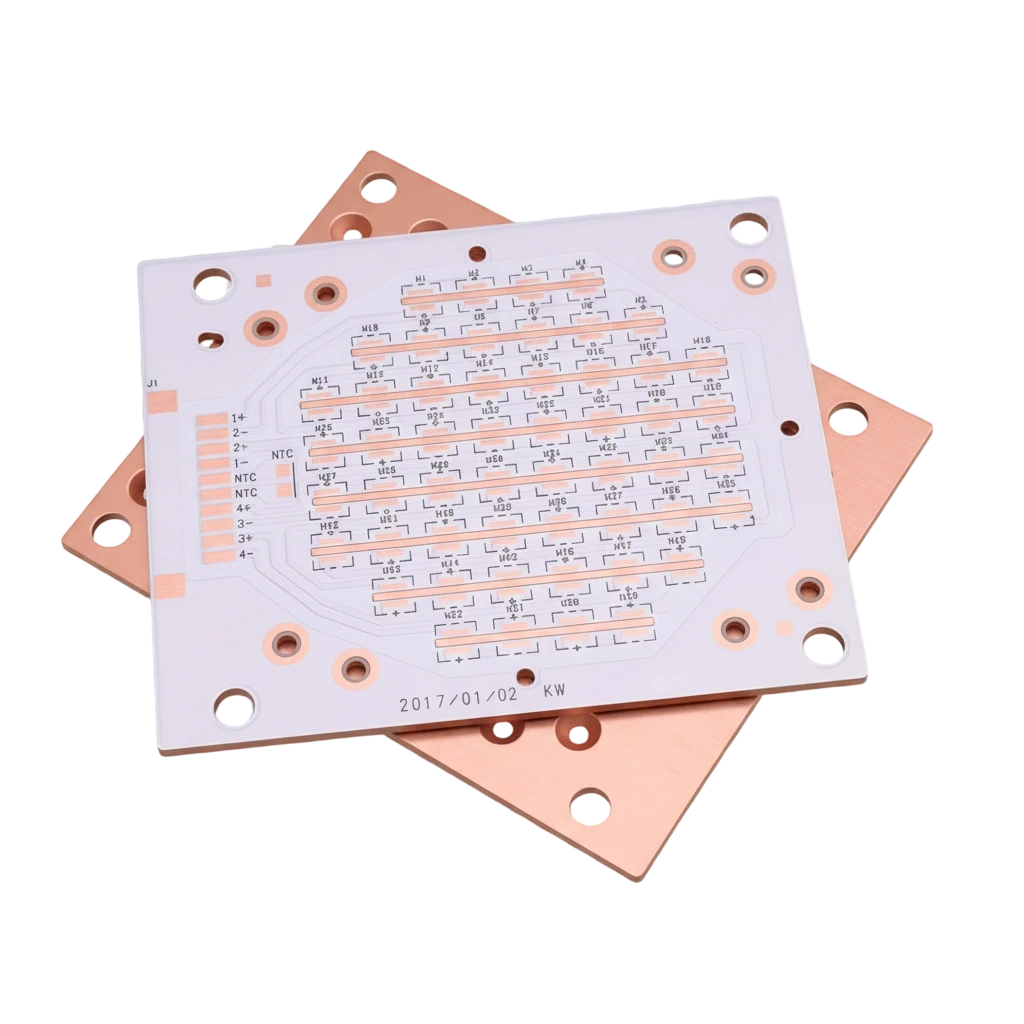

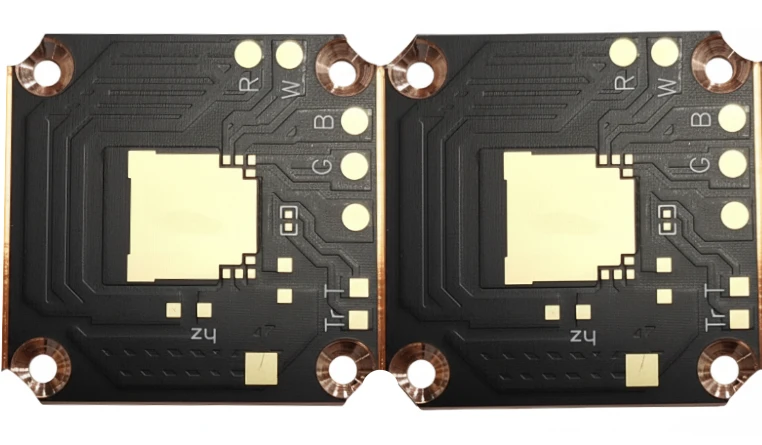

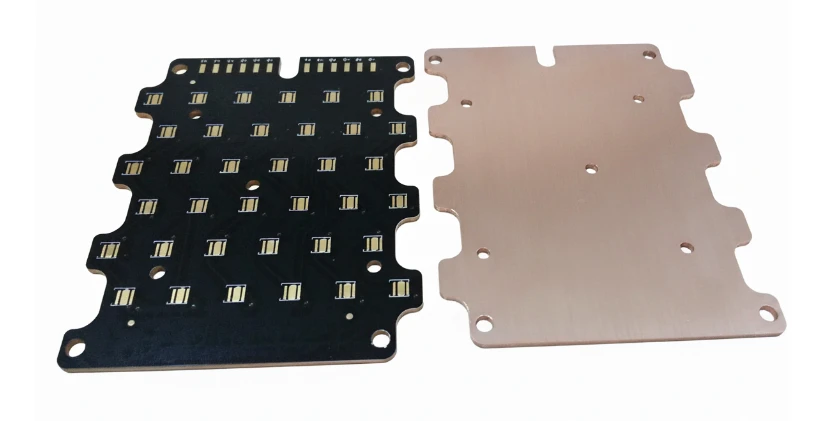

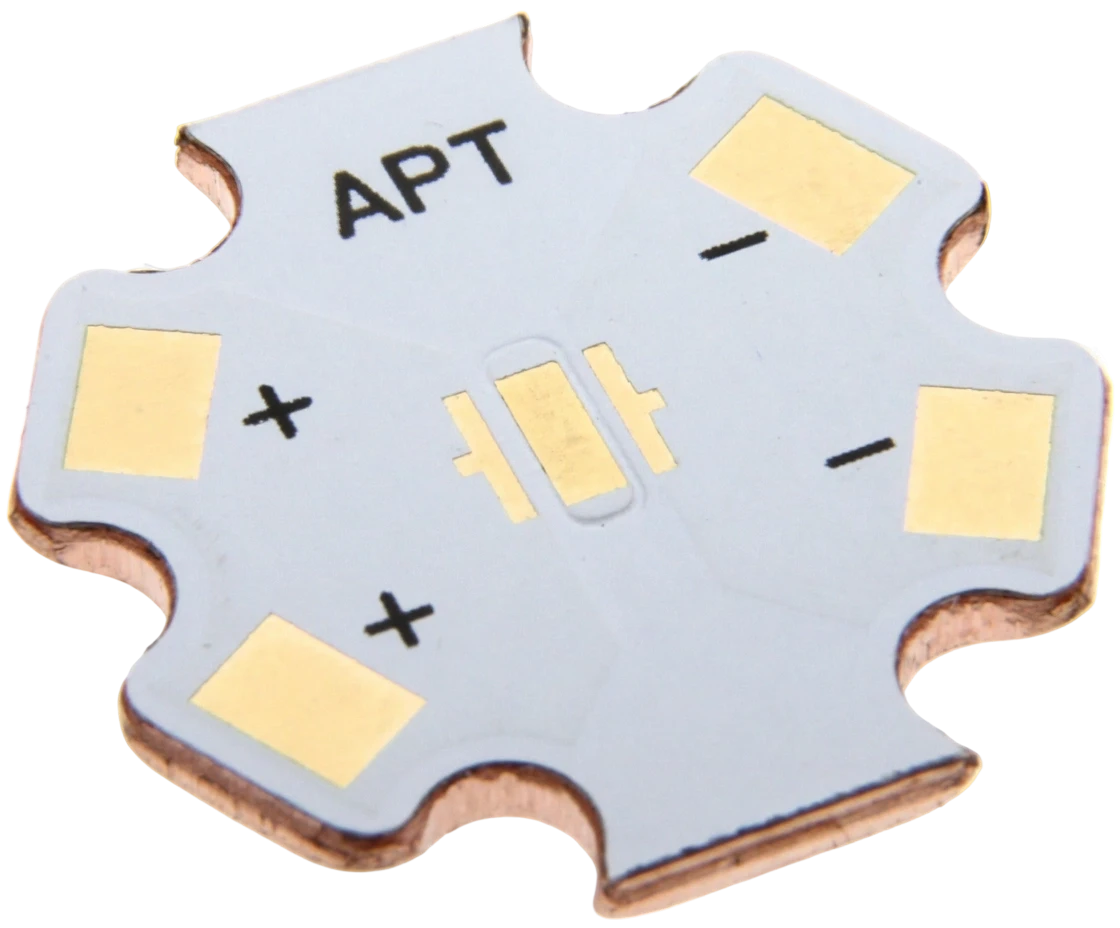

Define dielectric selection, copper thickness, and machining features before fab.

- Confirm conductivity, thickness, and voltage requirements.

- Plan copper thieving and relief to balance plating.

- Define coin/via patterns and flatness specs.

- Specify finishes and coating keep-outs for LEDs.

- Document bake and handling instructions for metal-backed boards.

- Provide packaging notes to prevent oxidation.