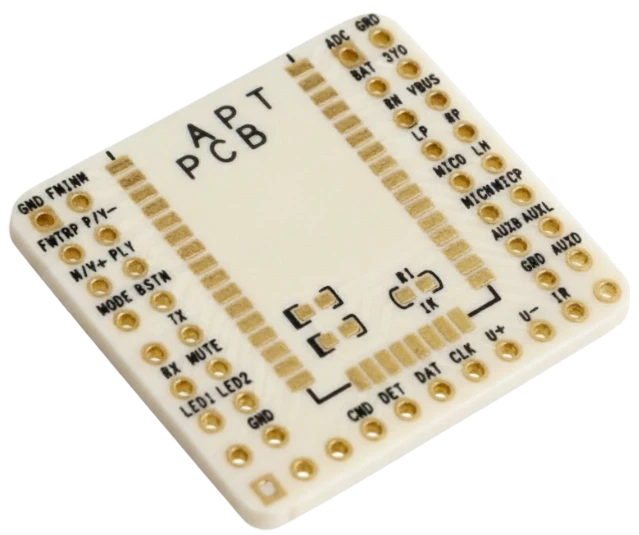

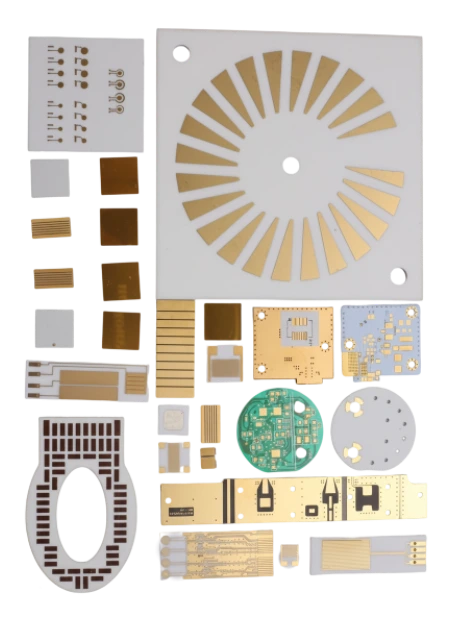

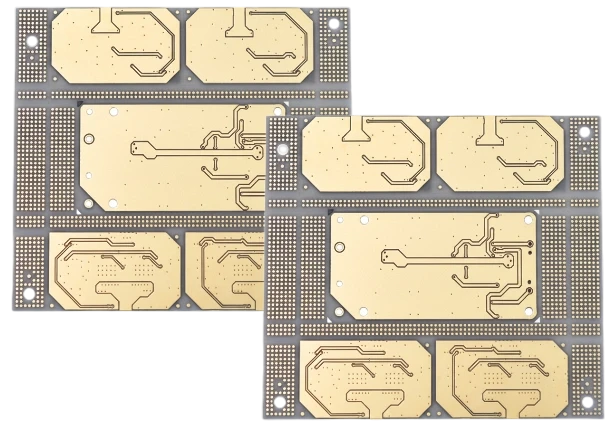

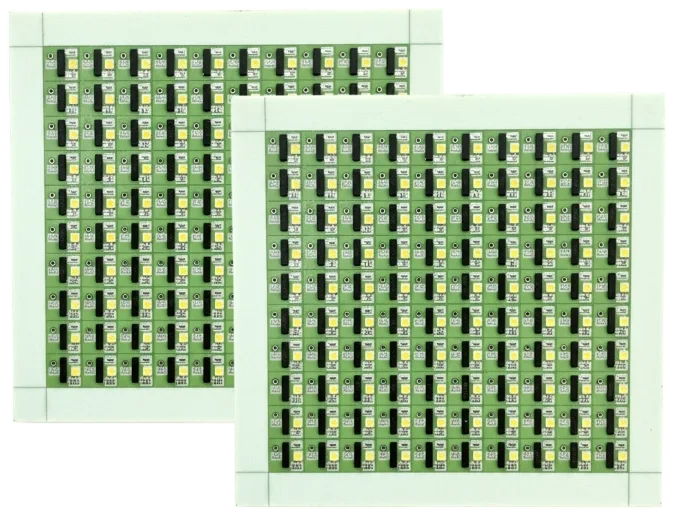

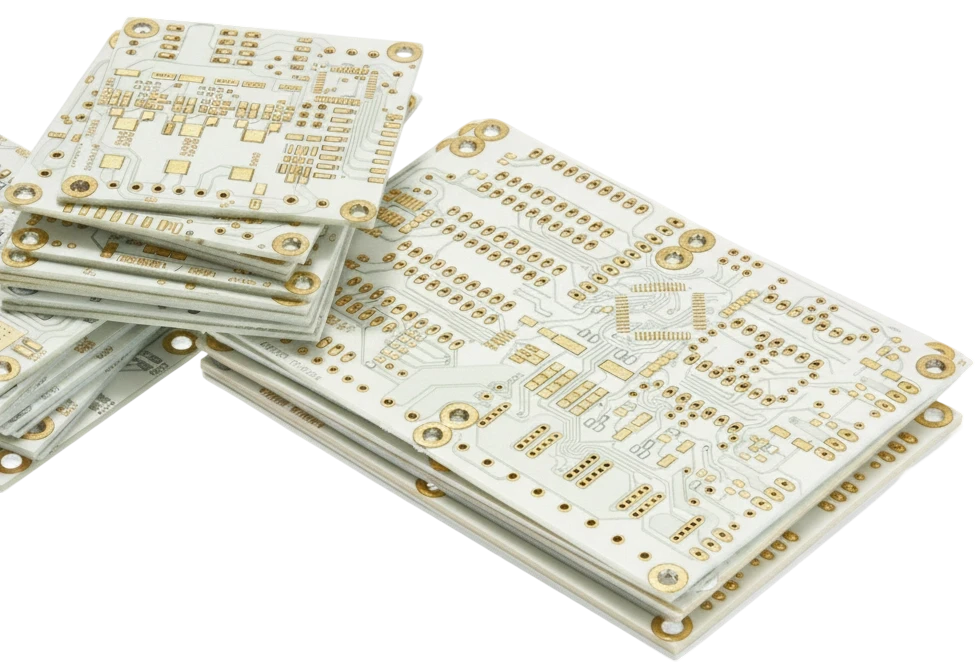

Ceramic Stackup Engineering

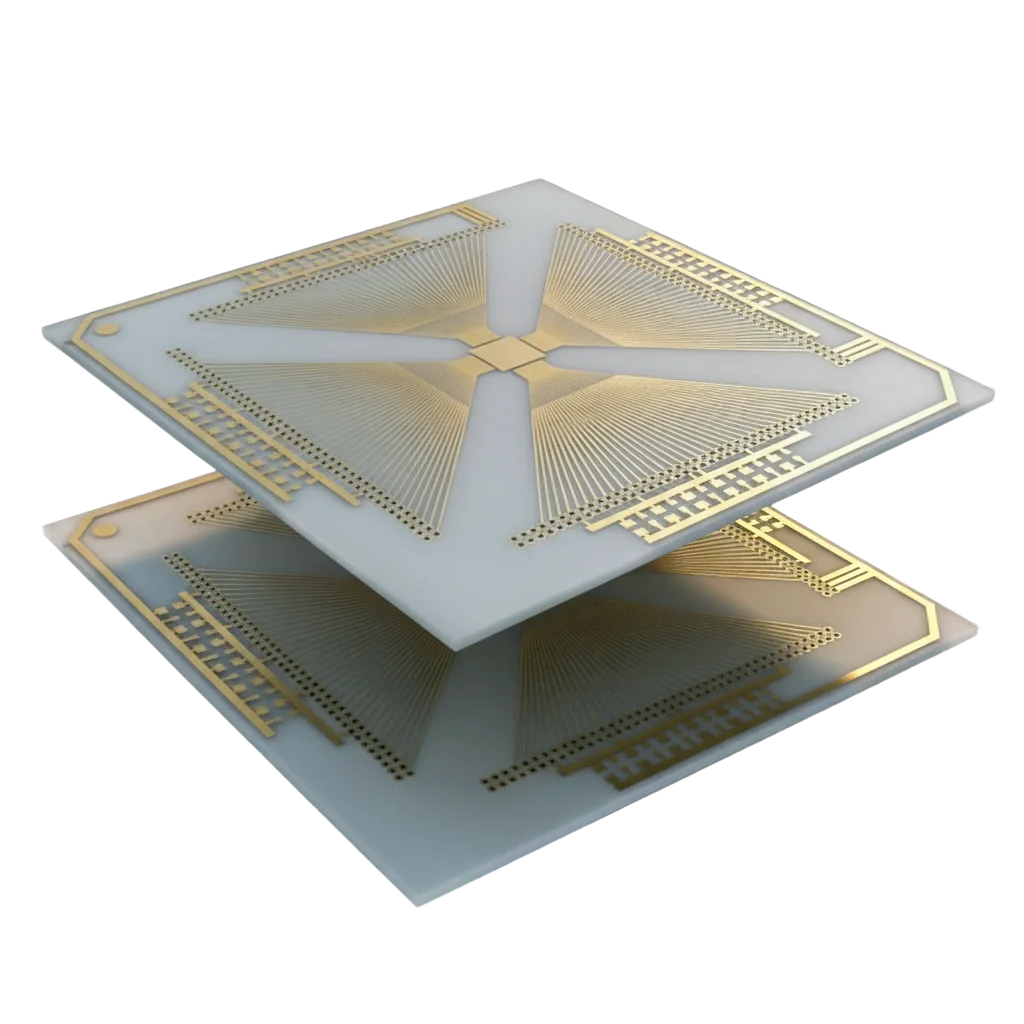

We plan dielectric, copper, and via features to meet thermal and electrical specs.

- Confirm substrate type and conductivity.

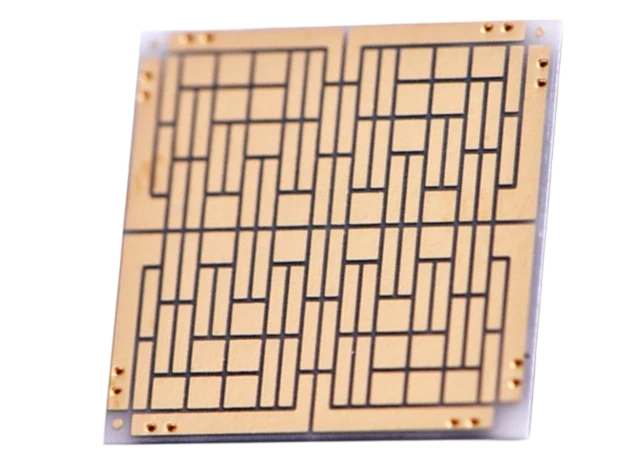

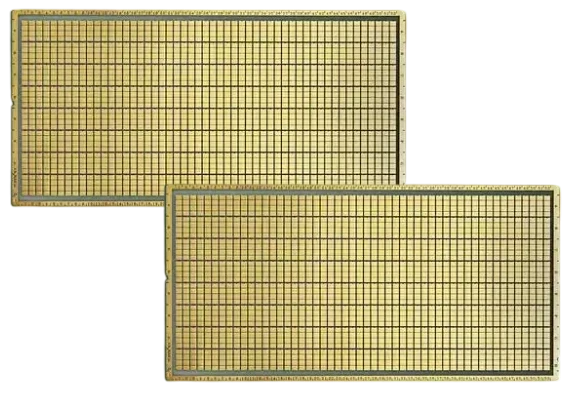

- Define copper thickness and plating requirements.

- Plan laser drilling and cavity machining.

- Specify finishes and masking.

- Document bake/handling for ceramic panels.

- Provide packaging instructions for fragile substrates.