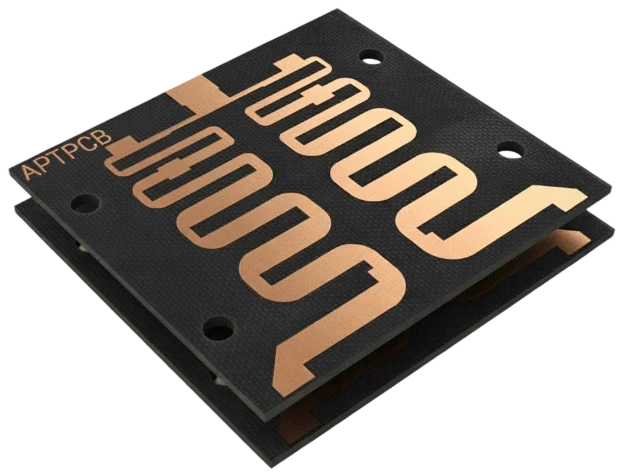

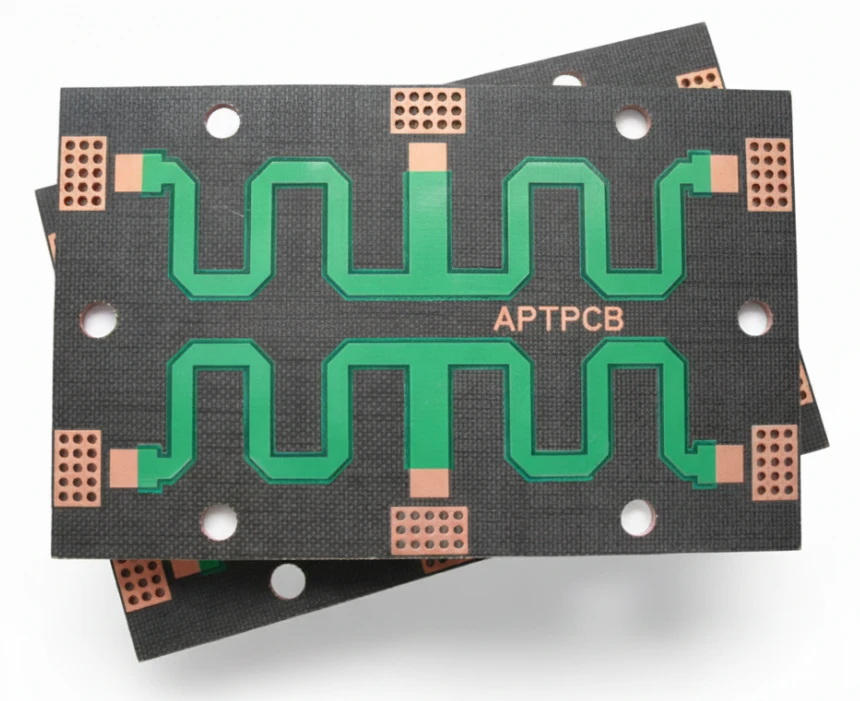

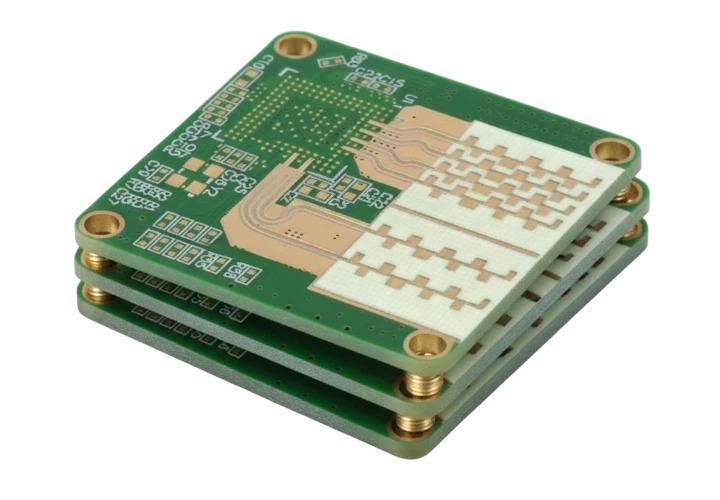

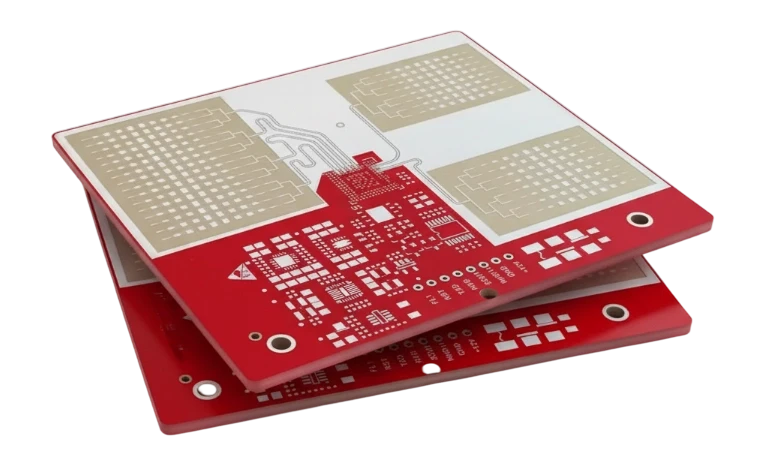

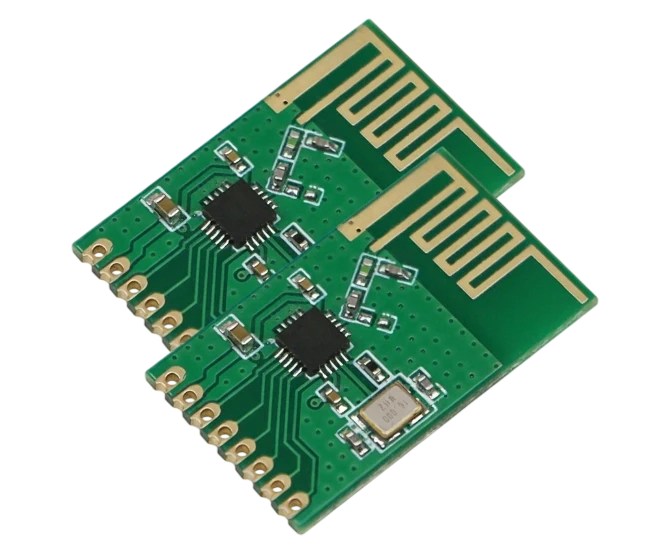

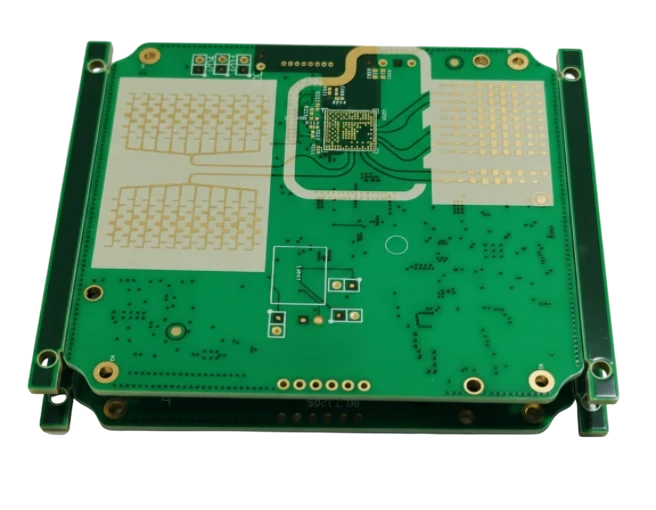

RF Stackup Engineering

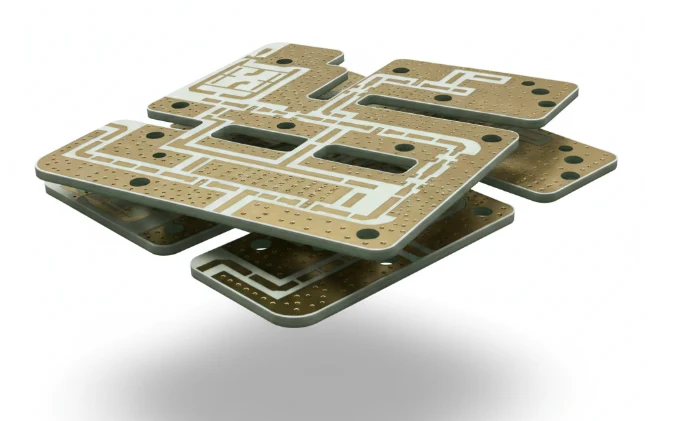

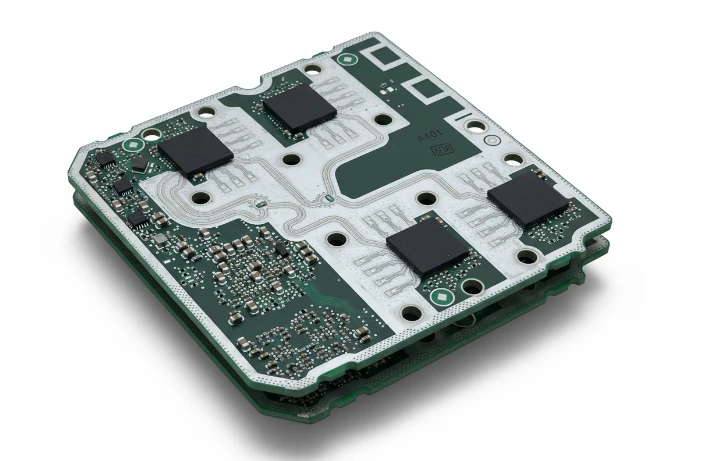

We assist with stackup design, launch structures, and impedance modeling.

- Confirm materials and acceptable alternates.

- Define cavity depths and slot dimensions.

- Plan impedance coupons and VNA fixtures.

- Specify finishes and coating keep-outs.

- Document handling for PTFE/ceramic substrates.