PCBA Quality Inspection

PCBA Quality Inspection Services – Ensuring Excellence and Unmatched Reliability

Our multi-layered quality inspection keeps every PCBA “plug-and-play” ready—catching defects from design through final cleaning so your boards perform reliably in the field.

Get an Instant Quote

Comprehensive PCBA Quality Assurance Process

Our PCBA quality inspection process is a multi-layered, systematic approach designed to detect and prevent defects from the very beginning. The goal: every PCBA you receive is “plug-and-play” ready for your product line without further intervention.

1) Design Evaluation (DFM/DFT Support)

Quality starts in the design phase. If you want to reduce defects and test difficulties from the start, we can assist before production begins:

- DFM (Design for Manufacturability) Review: We ensure your PCB designs are optimized for manufacturing efficiency.

- DFT (Design for Testability) Support: We ensure your designs are structured to be easily tested during production, minimizing testing challenges later on.

- PCB Layering, Routing, and Test Point Layout Suggestions: Our engineers work with your team to identify potential risks and address them early in the design phase, ensuring smoother production later on.

2) Incoming Quality Control (IQC)

All components, whether PCBs or electronic components, undergo rigorous inspection before they are even placed on the production line:

- PCB Inspection: Checking dimensions, hole sizes, copper thickness, solder mask, and character printing; verifying no scratches, warping, or delamination.

- Component Inspection: Verifying model, brand, batch, date codes, packaging, and any signs of defects like pin oxidation, bending, or contamination. For key components (e.g., MOSFETs, ICs), we may perform electrical performance testing to ensure conformity to specifications.

4) Advanced Detection Methods

- AOI (Automatic Optical Inspection) Post-reflow: High-speed cameras identify misalignment, solder bridges, missing components, and incorrect polarity—crucial for medium-to-large batches and complex BOMs.

- X-Ray Inspection (AXI) for Hidden Solder Joints: For BGA, QFN, CSP, and hidden joints, AXI detects voids, bridges, cold joints, misalignments, and pad/ball fusion quality.

5) Electrical and Functional Validation

- ICT (In-Circuit Testing): For high-volume or mission-critical builds, checks components and connections for shorts/opens, tolerances, and accurate connectivity.

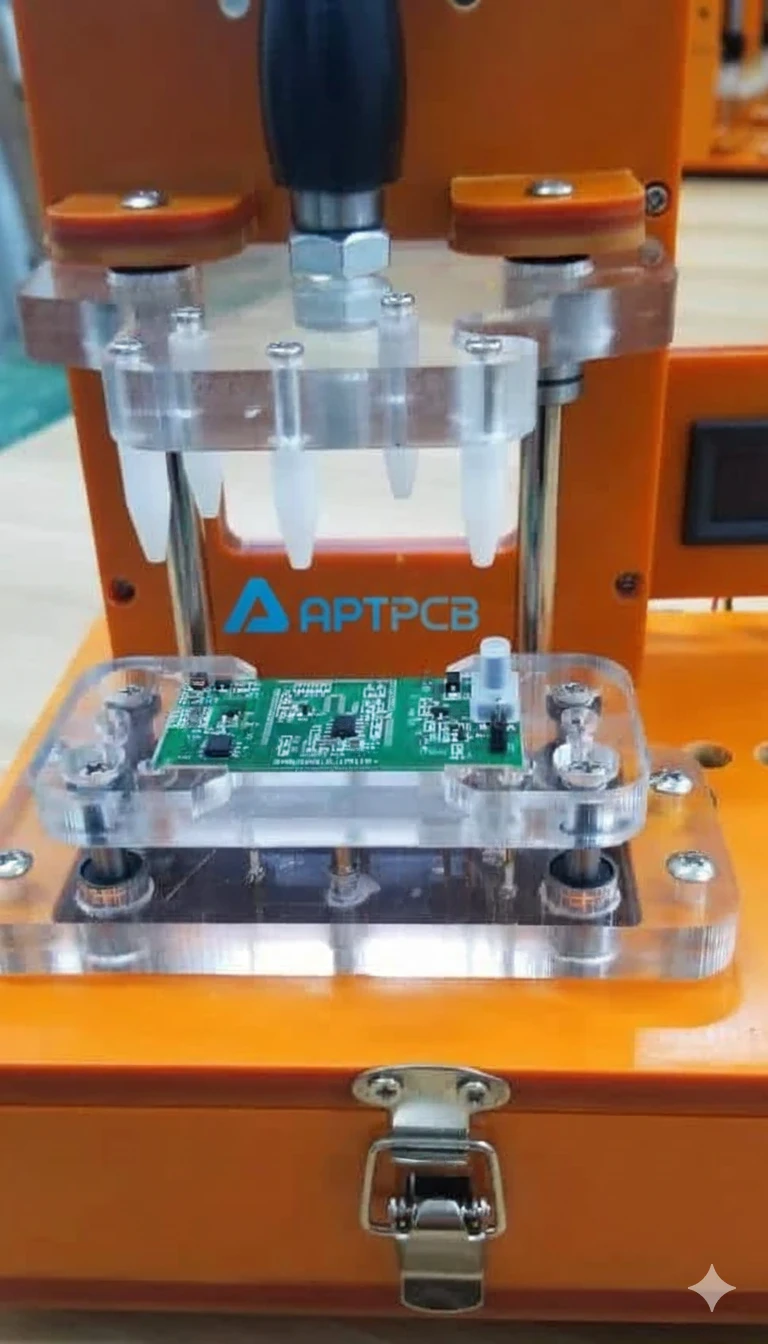

- FCT (Functional Circuit Testing): Simulates operational environments—voltage/current/frequency checks, I/O and interface tests (USB, Ethernet, UART), and peripherals like buttons, LEDs, sensors.

- Burn-in Testing: Stresses PCBAs under high temperature, humidity, and power to surface early failures for high-reliability products (industrial, medical, telecom).

6) Final Visual Inspection and Cleaning

After all testing, experienced quality personnel check cosmetic defects, cleanliness (flux residues, fingerprints), and structural integrity. Boards are then cleaned with IPA or other agents to ensure the PCBA is free from contaminants.

Why Choose APTPCB for Your PCBA Quality Testing Services?

- Comprehensive Integration: Quality testing embedded through the entire PCB manufacturing and assembly process for a one-stop solution.

- State-of-the-art Testing Equipment: SPI, AOI, AXI, ICT, FCT, and burn-in testing to ensure thorough assurance.

- Experienced Quality Team: IPC-certified engineers and technicians skilled in failure analysis and process optimization.

- Traceability: Robust traceability from component batch to production lot for full visibility.

- Customizable Testing Solutions: Tailored validation per product needs, including custom functional and aging tests.

Get in Touch with APTPCB for Reliable PCBA Quality Testing Services

If you need a trusted partner for PCB manufacturing and PCBA assembly with top-notch quality control and testing services, we can:

- Assess the current testing coverage of your product.

- Provide customized PCBA quality testing solutions.

- Offer competitive quotes and delivery timelines.

By partnering with APTPCB, you ensure your products meet and exceed the highest standards of reliability and performance, ready to thrive in the marketplace.

Request PCBA Quality Inspection Support

Share your BOM, Gerber, test strategy, and reliability targets—we’ll return a tailored inspection plan, coverage notes, and a quote.