Flex CAM Engineering & DFx Review

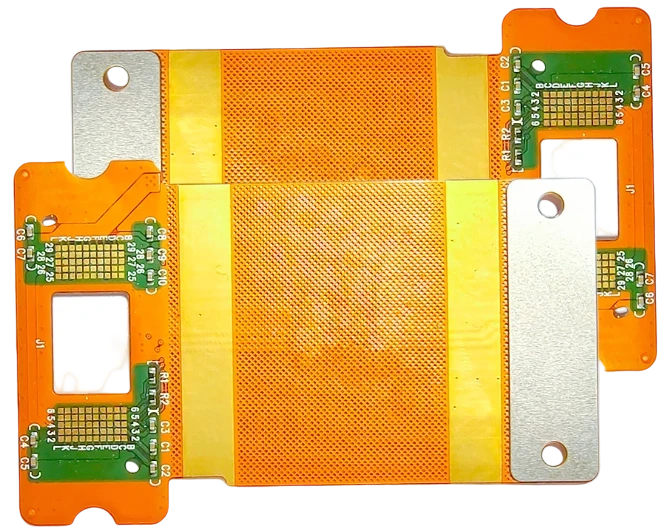

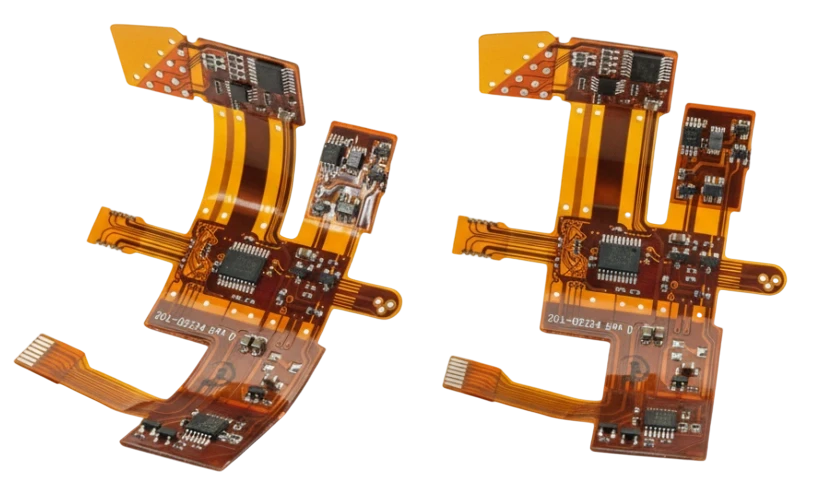

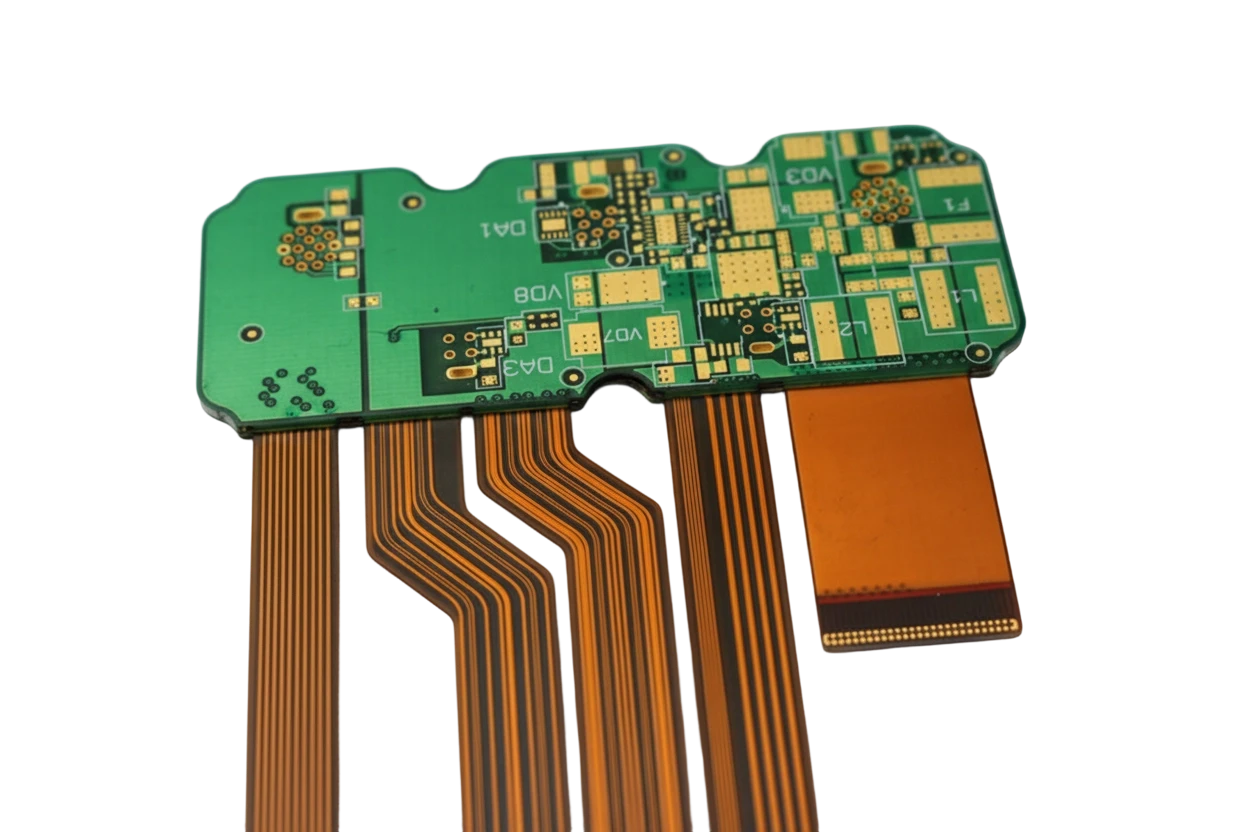

CAM engineers extract bend stack-ups, impedance targets, and stiffener callouts from ODB++ files, then create relief patterns, hatched grounds, and carrier tooling before routing to production.

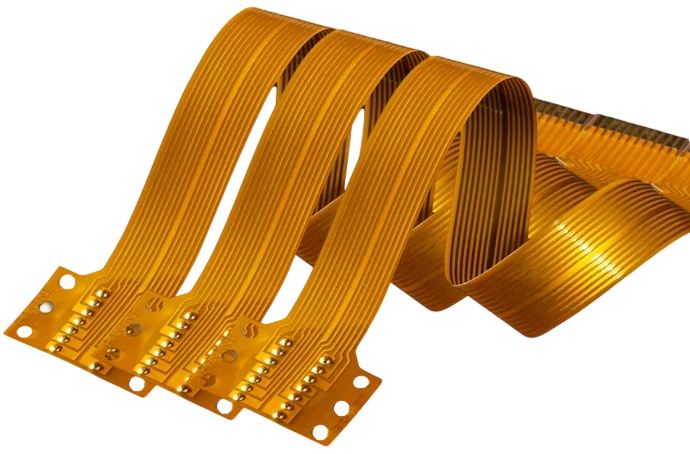

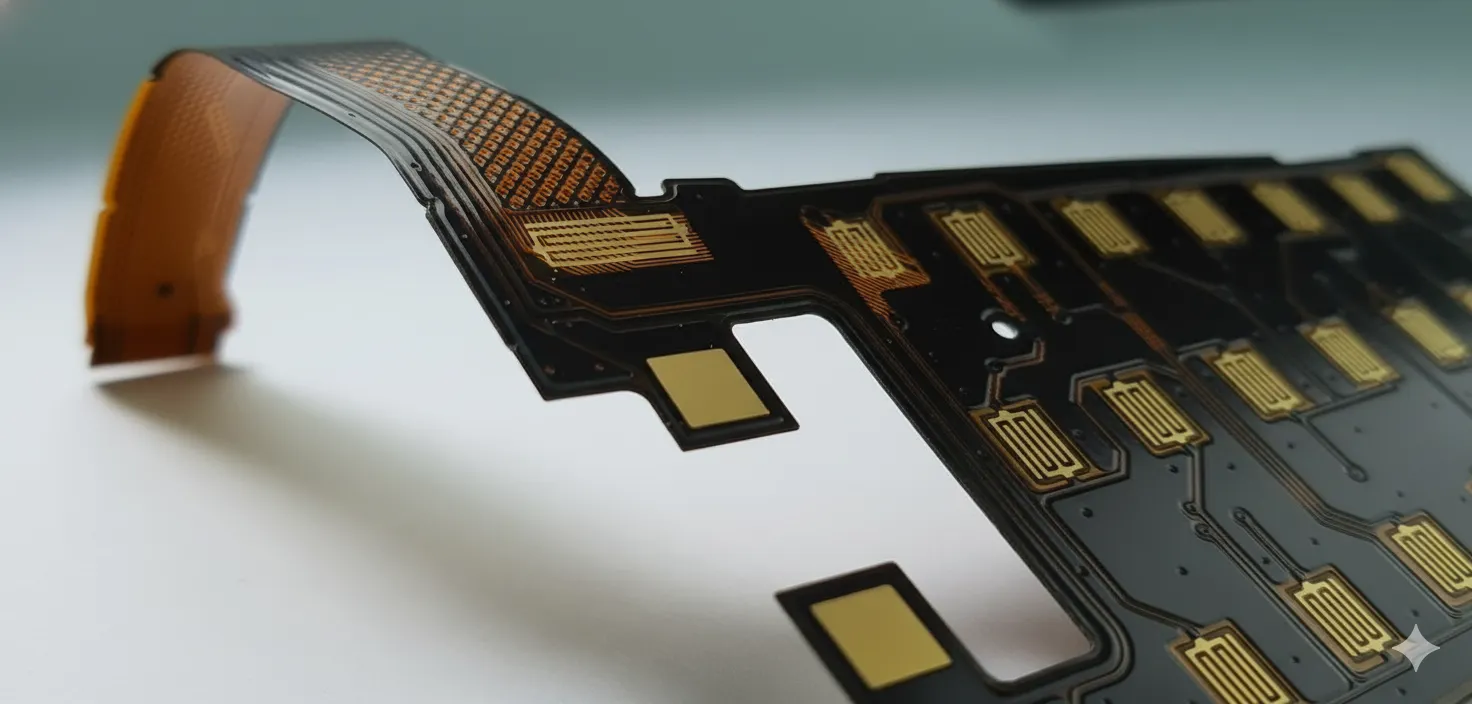

- Verify bend zones, neutral axis placement, and keep-out regions before tooling.

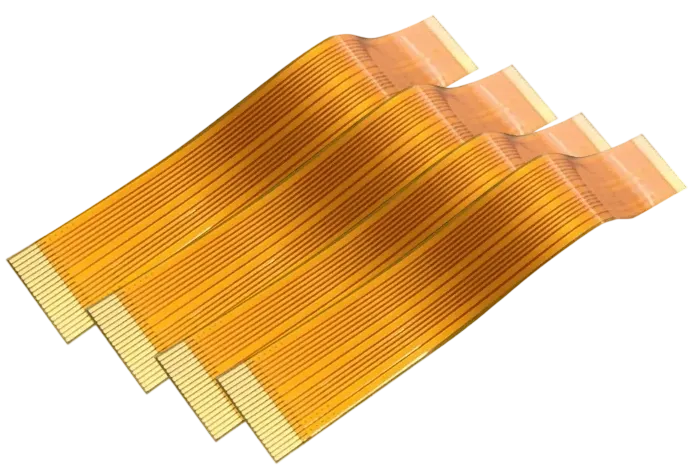

- Confirm stack-up thickness, copper grain direction, and impedance meshes for each layer.

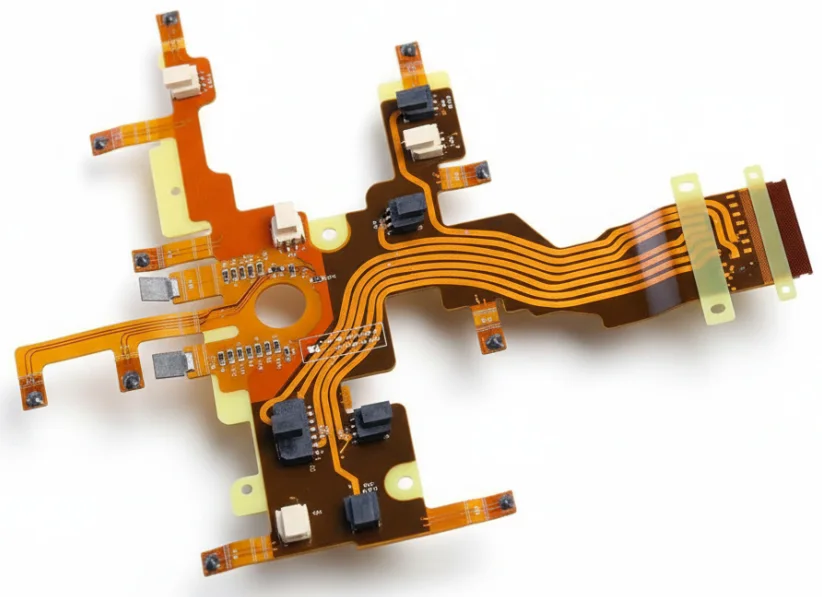

- Generate coverlay relief, hatched grounds, and tear-stop features.

- Define stiffener outlines, PSA windows, and depth-controlled rout paths.

- Annotate impedance coupons, dynamic test coupons, and handling instructions.

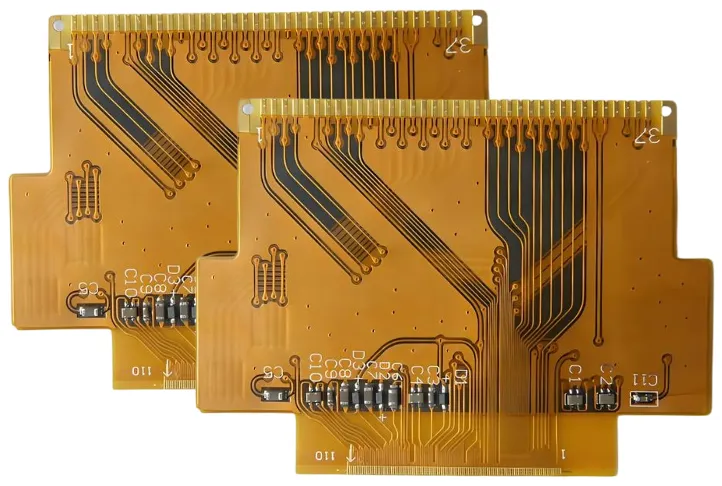

- Optimize panel utilization with shared carriers and fiducials for SMT.

- Release fabrication notes covering bake cycles, cleanroom requirements, and packaging method.