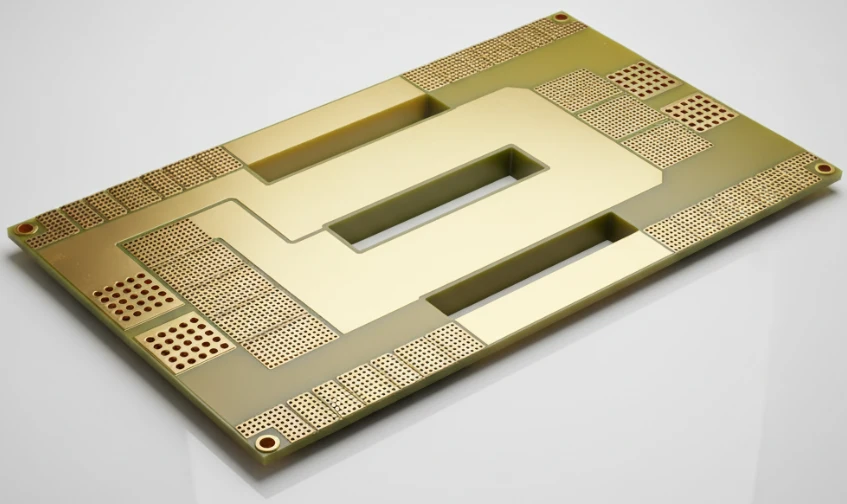

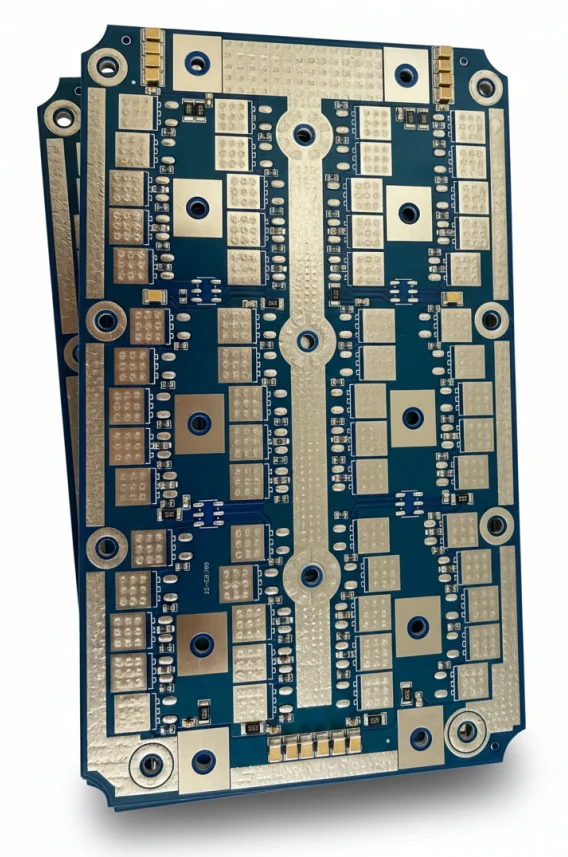

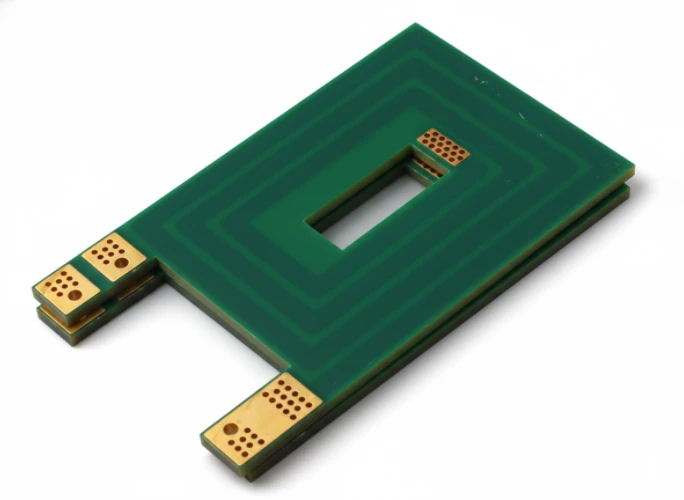

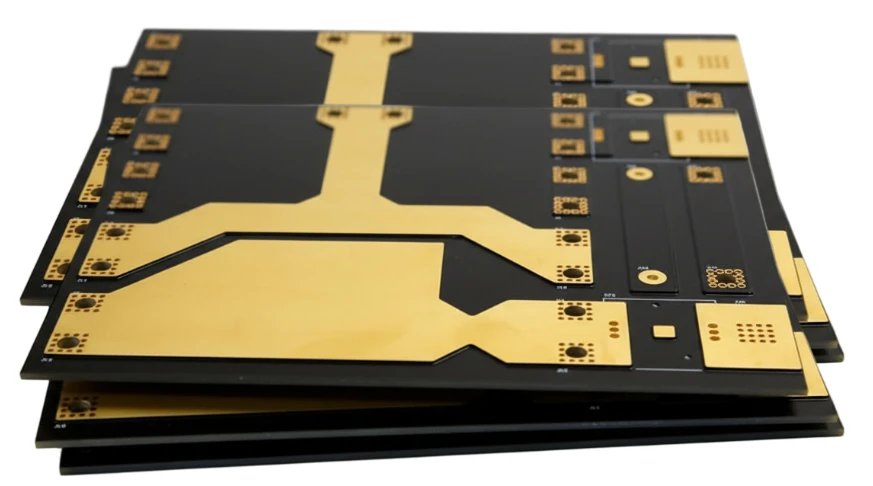

Heavy Copper CAM & Stackup Engineering

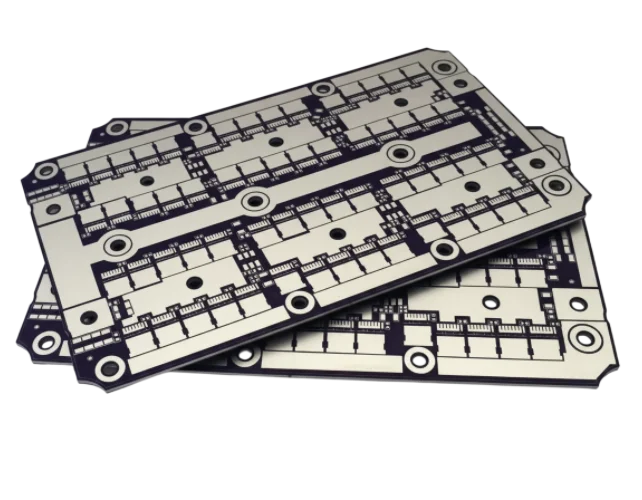

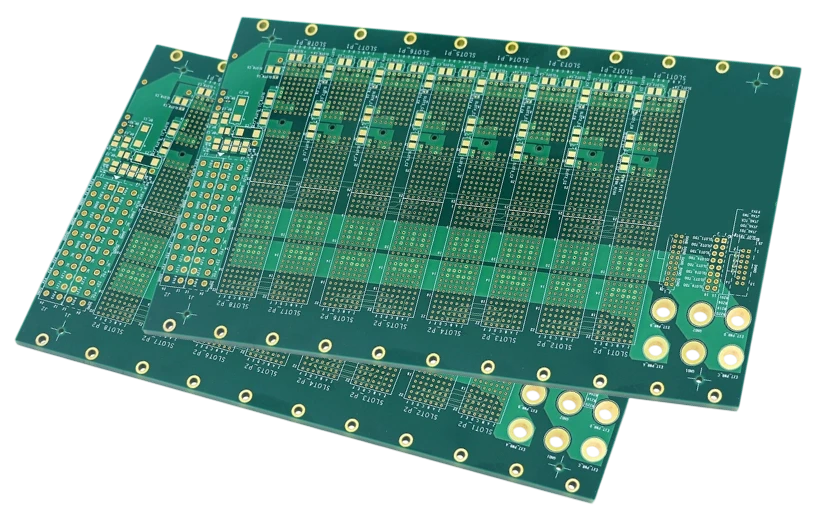

CAM teams map copper balance, plating schedule, and thermal via patterns before manufacturing.

- Confirm copper thickness per layer and plating sequence.

- Define thieving, resin dams, and relief patterns to manage plating.

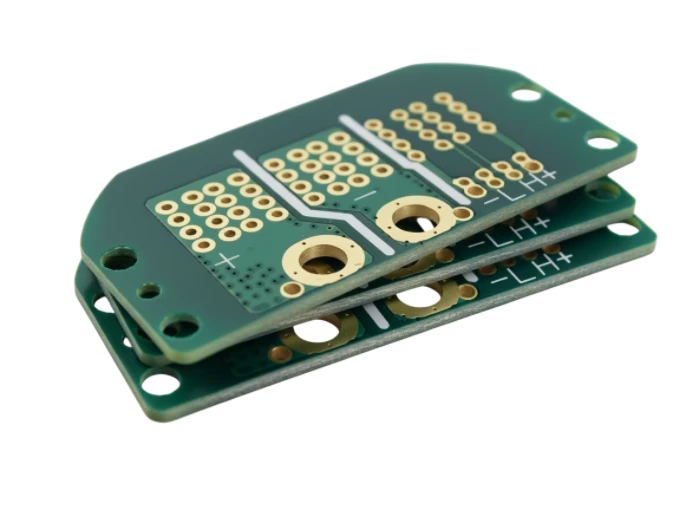

- Plan thermal via arrays and copper coins where needed.

- Document drill/press-fit tolerances and torque specs.

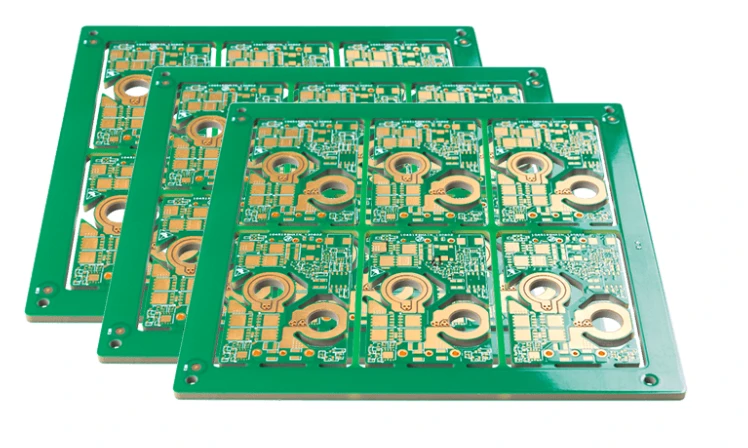

- Specify surface finish (ENIG, tin, silver) for high-current pads.

- Provide assembly notes for heatsinks, studs, or potting.

- Release packaging requirements for heavy panels.