High-Temp Polyimide Platforms

33N/35N/85N hold Tg >250 °C with low CTE, perfect for avionics, burn-in, and metal-backed packages.

- Low-flow options (38N/37N) for bonding

- Matched to 0.8–1.3 ppm/°C Cu CTE

- Supports sequential lam HDI

Materials

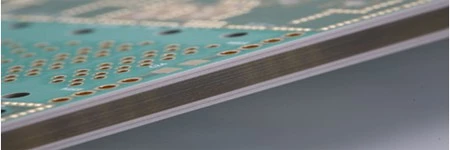

We manufacture Arlon polyimide, multifunctional epoxy, Thermount®, and CLTE/TC microwave laminates for avionics, RF, and rugged industrial programs. Using data captured from RayPCB builds, we catalog press curves, low-flow behavior, and microwave validation artifacts so 33N/35N, 45N, Thermount®, and CLTE-XT stacks meet IPC/MIL and RF targets.

33N/35N/85N hold Tg >250 °C with low CTE, perfect for avionics, burn-in, and metal-backed packages.

Thermount® 55NT/85NT minimizes moisture uptake and warpage in mission-critical control electronics.

CLTE-XT, TC350/600, and AD-series deliver Df down to 0.0009 with low PIM for phased arrays and satcom payloads.

| Series | Primary Use | Examples |

|---|---|---|

| Polyimide | Avionics, burn-in, metal-backed | 33N, 35N, 85N, 38N |

| Multifunctional Epoxy | Lead-free digital/HDI builds | 45N, 47N, 49N, 44N |

| Thermount® | Low moisture & low CTE control | 55NT, 55LK, 85NT |

| Microwave PTFE | RF/microwave arrays, radar | CLTE-XT, CLTE-MW, TC350, TC600 |

| Bondply / Adhesives | Hybrid integration | HF-50, 37N low-flow, PTFE bondply |

| Material | Dielectric Constant @1 MHz/10 GHz | Df | Notes |

|---|---|---|---|

| 33N Polyimide | 3.5 @1 MHz | 0.015 | High-Tg, low-flow for bonding copper coins |

| 35N High-Temp | 3.5 @1 MHz | 0.012 | Preferred for avionics backplanes |

| 45N Multifunctional Epoxy | 3.7 @1 MHz | 0.014 | Lead-free compatible HDI builds |

| Thermount® 55NT | 3.5 @1 MHz | 0.017 | Reinforced non-woven aramid |

| CLTE-XT | 2.94 @10 GHz | 0.0015 | Low PIM microwave laminate |

| TC350 | 3.5 @10 GHz | 0.003 | 0.85 W/m·K thermal conductivity |

Values referenced from Arlon datasheets mirrored on RayPCB; verify against lot-specific certs for solver accuracy.

33N/38N cores with HF-50 bondply and copper coins for thermal paths.

Thermount® 55NT outer plies bonded to 45N epoxy for rugged controllers.

CLTE-XT RF layers mixed with 45N support and aluminum backers.

Press temperature/pressure ramps recorded for each polyimide lamination.

Thermount® and polyimide baked at 125 °C before fabrication to limit moisture and blistering.

Copper coin and aluminum backer interfaces documented with bond films and torque specs.

CLTE/TC builds get TDR, VNA, and, when required, PIM testing.

33N/35N polyimide backplanes with copper coins and press-fit connectors.

CLTE-XT/TC350 arrays with low PIM plating and cavity machining.

Thermount® reinforced controllers requiring low moisture and high stability.

Inputs gathered before we freeze Arlon material decisions.

Target temperature, PIM, and moisture conditions inform polyimide vs Thermount vs PTFE.

Define where Arlon polyimide meets FR-4, PTFE, or metals.

Plan IST, CAF, TDR/VNA, and ESS deliverables.

We keep 33N/35N polyimide, 45N/47N epoxies, Thermount® reinforcements, and CLTE/TC microwave cores with matching bondply. Specialty thicknesses can be sourced in 1–2 weeks.

Yes. Polyimide or epoxy support layers can be combined with PTFE microwave sections using HF-50/37N low-flow or PTFE bond films while logging press curves and CTE data.

Standard deliverables include AOI, ET, IST/CAF (when required), TDR for impedance layers, and VNA/PIM for microwave stacks.

Send 33N/35N/Thermount layer counts, temperature targets, and microwave goals—we'll reply with press curves, bondply picks, and a priced build plan within one business day.