Stencil Lab

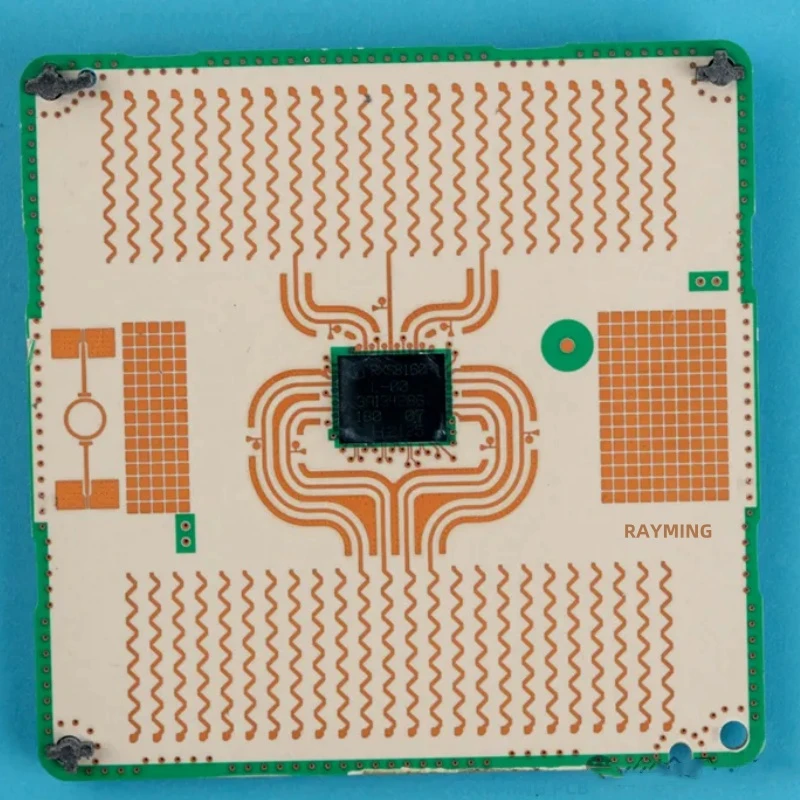

Stencil & paste control

Laser stencils, step-down, coating, cleaning, and storage routines tied to SMT line release.

- 24 h CAD -> laser

- DOE with aperture swaps

- Paste lot + wipe log

ENABLEMENT

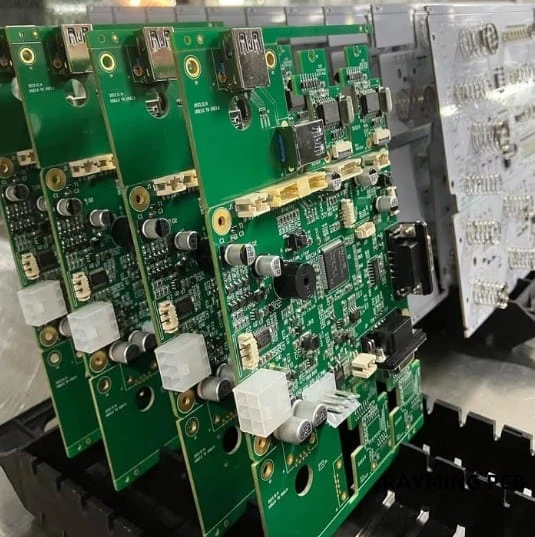

Mirror-site data shows that programs stay predictable when one crew owns every supporting service: stencil and paste control, AVL-backed materials, IC programming, surface protection, rework, flux governance, and cable/harness builds. We package all of it with the same traveler as SMT/box build so coverage and documents stay synchronized.

Dedicated crews own stencil-to-packaging routines so PCBA, test, and logistics never wait for missing support steps.

COVERAGE

Stencil, sourcing, programming, protective coatings, rework, flux governance, and electro-mechanical harness builds share planning data with SMT/box build.

Stencil & print lab

24 h release, DOE, paste control, storage, and wipe audit tied to SMT travelers.

Component governance

AVL-backed kitting, MSD handling, anti-counterfeit inspection, and consigned intake.

Programming & protection

IC programming (SW/HW load), plasma clean, conformal coat, potting, and bake routines.

Mechanical build

Selective solder, BGA reball/repair, cables, harnesses, and pack-out ready for box build.

PLAYBOOK

Standard gates keep each service audit-ready before SMT or box build.

Plan & quote

Intake stencil data, AVL, firmware, coating notes, harness drawings, and logistics requirements.

Stage & qualify

Laser stencils, prep fixtures, bake MSD kits, stage flux/paste lots, and validate harness tooling.

Execute service

Programming, selective solder, BGA reball, coating, cleaning, harness/cable builds per traveler instructions.

Inspect & log

AOI/X-ray, cleanliness, drip charts, torque/continuity logs, photos, and serialization tied to MES.

Handoff

Release kits or sub-assemblies to SMT/box build, ship to customer, or store with bonded inventory.

MODULES

Pick the combinations you need or let us pre-package them for turnkey PCBA/box build programs.

Stencil Lab

Laser stencils, step-down, coating, cleaning, and storage routines tied to SMT line release.

Materials

AVL review, alternates, MSD conditioning, anti-counterfeit screening, and consigned intake before SMT.

Firmware

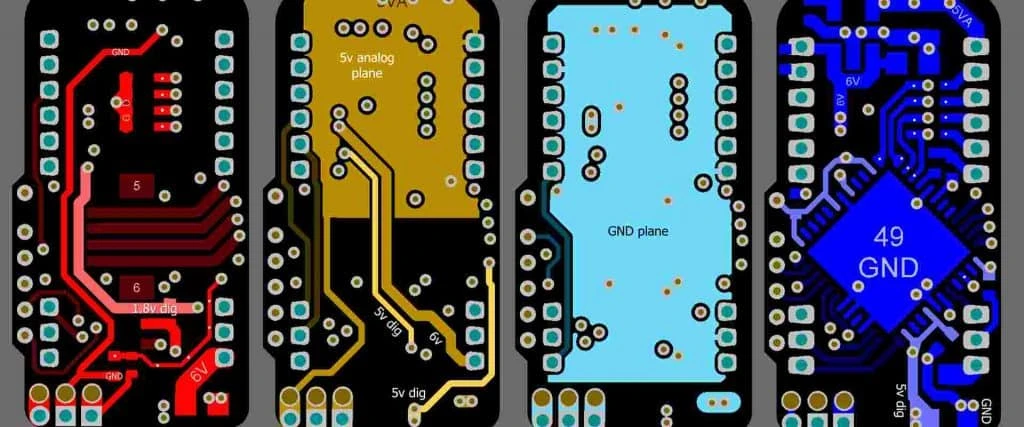

Load firmware via SWD/JTAG/USB, log revisions, serialize MAC/keys, and provide golden-unit compare.

Protection

Surface prep, masking, spray/dip/robot coat, UV bake, and ionic/ROSE proof for Class 3 builds.

Through-Hole

Lead-free selective solder with nitrogen, drip charts, Ti pallets, plus epoxy/potting and cure logs.

Rework

Micro BGA reball, pad repair, CSAM/X-ray validation, and documented reflow profiles for audits.

Chemistry

Flux selection, solids %, preheat, and audit trail plus fallback wash/plasma when customers require data.

Systems

Cut/strip/crimp coax, power, and signal cables with continuity/hipot data, labeling, and kitting.

Integration

Harness boards, lacing, bundling, labeling, and torque/continuity data ready for box build or shipment.

PROGRAMS

How different industries package support services around SMT and box build.

CAPABILITIES

Specs that wrap around assembly so every lot ships ready for integration.

Every service runs on documented travelers with SPC, cleanliness, torque, or continuity data ready for audits.

QUALITY

Stencil DOE, MSD logs, flash code verification, drip charts, ionic cleanliness, CSAM/X-ray, and continuity/torque data stay inside MES with photos for audits.

Travelers include DOE, program logs, cure recipes, and cleanliness results.

AOI/X-ray/CSAM on rework, ionic & UV inspection on coating, 100% continuity on cables/harness.

Flux lots, firmware revisions, harness serials, and torque/continuity data link to packing lists.

Step stencils, selective solder, conformal, PPAP logs, torque data.

MSD control, firmware security, cleanliness proof, sterilizable harness.

RF cable tuning, flux control, BGA reball with CSAM proof.

Potting, heavy harness, hi-pot, and coated assemblies ready for harsh installs.

Everything you need to know about HDI PCB technology

Send BOM/AVL, firmware, coating maps, harness drawings, or rework scope. We respond with plan, cost, and readiness checkpoints.