Industry 4.0 Process Control • Scalable Capacity • Stable Cost Per Unit

High-Volume Mass Production PCB Manufacturing

For OEMs and brands planning large, repeatable production runs, mass production PCB manufacturing is not just about capacity — it is about stability, process control, and predictable cost per unit. We structure our fabrication lines specifically for high-volume jobs, ensuring that the 100,000th PCB in a batch performs exactly like the first.

Get an Instant Quote

Key Mass Production PCB Fabrication Capabilities

Benefits for High-Volume OEM and EMS Customers

By treating every mass production PCB manufacturing project as a long-term program rather than a one-off order, we help you stabilize per-unit costs and reduce the time and effort required for each repeat build.

Stable processes, predictable lead times, and documented DFM recommendations give your engineering and supply chain teams a reliable basis for forecasting, budgeting, and long-term platform planning.

Turnkey High-Volume PCB Assembly and Box Build for Mass Production

The Ramp-Up Journey

DFM & Engineering Review

Comprehensive analysis of your design for yield, cost, and testability. We propose panelization strategies and material alternates to secure the supply chain.

Pilot Run (PVT)

Small-volume production run (e.g., 100-500 units) to validate the manufacturing process, test fixtures, and quality control plans (Control Plan, PFMEA).

Quality Assurance

IPC-Compliant Quality Assurance for Mass Production PCB Manufacturing

In high-volume environments, even a small defect rate can translate into significant field failures, warranty costs, and brand damage. Our mass production PCB manufacturing and assembly processes are built around rigorous, standards-based quality control to ensure every shipment meets your reliability requirements.

Production aligned with IPC-A-600 and IPC-A-610 Class 2 and Class 3, supported by ISO 9001, ISO 13485, and IATF 16949 certified quality systems for industrial, medical, and automotive products.

Core Mass Production PCB Assembly Capabilities

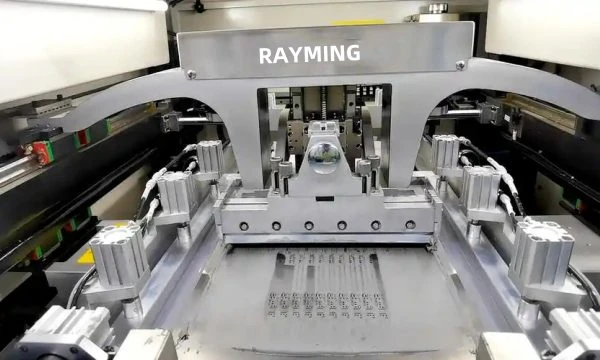

High-Speed SMT Lines: Automated placement lines (including Yamaha / Panasonic platforms) capable of mounting over 1 million components per day, supporting 01005/0201 passives, fine-pitch QFNs, BGAs, CSPs, and high-pin-count connectors.

Mixed-Technology Assembly: Integration of SMT, through-hole (DIP), press-fit, and odd-form components on the same product, using wave soldering, selective soldering, or controlled manual processes as appropriate.

Box Build and System Integration: Assembly of complete products — including mechanical assembly, cable harnesses, labeling, firmware programming, and functional test — delivered as ready-to-ship units.

Get a Mass Production PCB Quote

Whether you are ramping an existing product or preparing a new platform for global launch, we can help you move from trial builds to stable, high-volume supply. Share your Gerber/ODB++ files, BOM, and forecast for a tailored mass production proposal.

Frequently Asked Questions

Answers to the questions we hear most from hardware teams.

What is the minimum order quantity (MOQ) for mass production?

While we are flexible, mass production typically starts at 50-100 sqm or 5,000+ units, depending on board size and complexity. We also support smaller pilot runs during the NPI phase.

How do you handle engineering changes (ECOs) during volume production?

We have a strict ECO process managed through our MES. Changes are reviewed for impact on cost, tooling, and WIP. We implement cut-in dates to minimize scrap and ensure smooth transitions.

Do you offer buffer stock or consignment programs?

Yes, we offer Vendor Managed Inventory (VMI) and Kanban programs. We can hold finished goods in our warehouses to support your JIT delivery requirements and buffer against demand spikes.

Can you provide PPAP documentation for automotive orders?

Absolutely. We provide full PPAP (Level 1-5) documentation, including Control Plans, PFMEA, MSA studies, and dimensional reports, as required by IATF 16949.

What are your standard lead times for volume orders?

Standard lead times are typically 3-4 weeks for fabrication and 4-6 weeks for turnkey assembly, depending on material availability. We can also arrange expedited production for critical shortages.