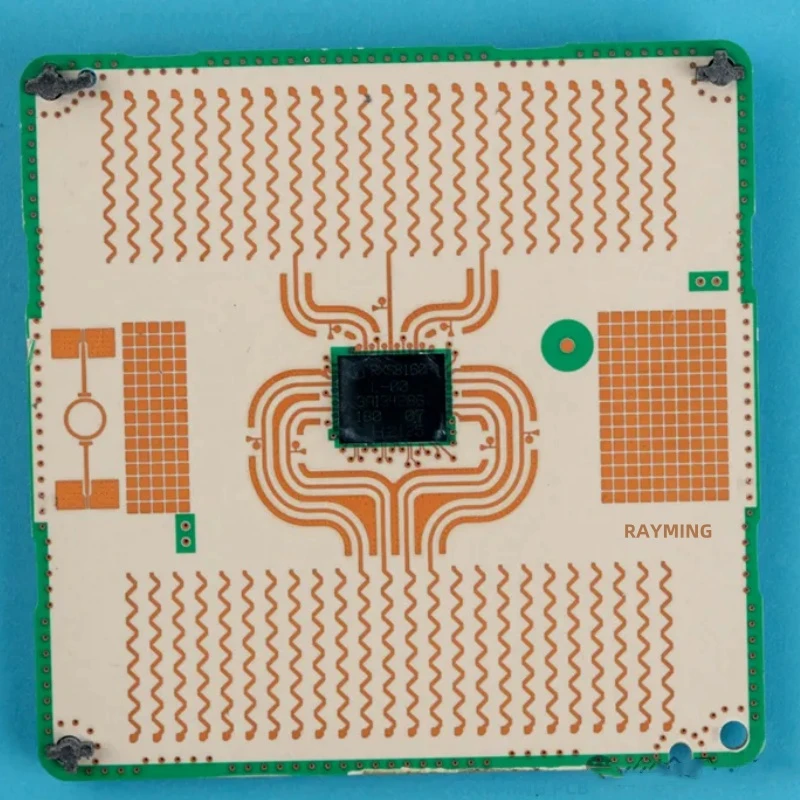

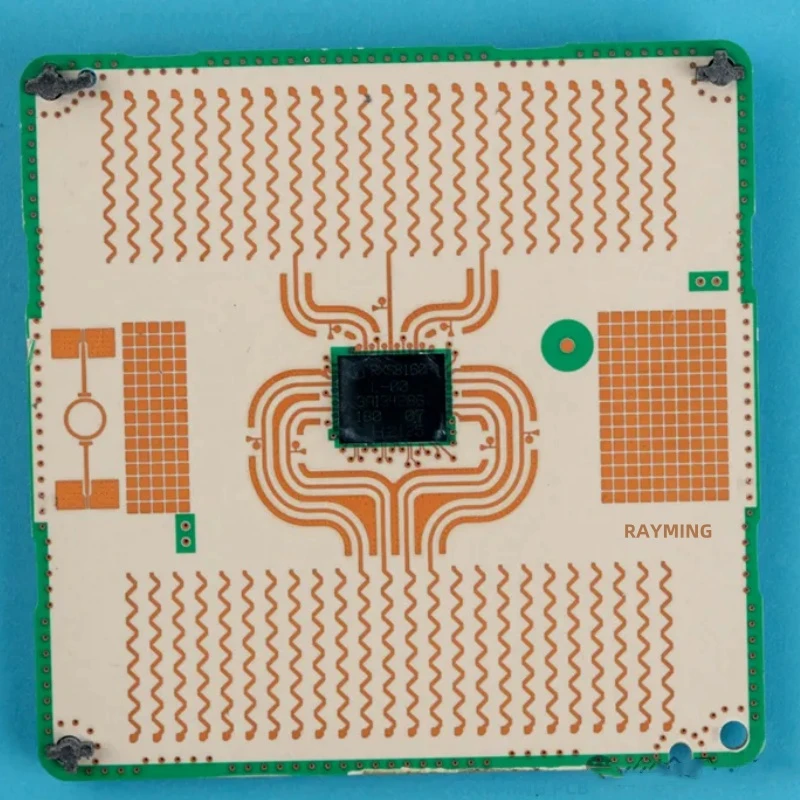

Automotive

Automotive control unit

01005–press-fit with selective solder, hi-pot, and PPAP reporting.

SelectivePPAPHi-pot

01005 • SELECTIVE SOLDER • ICT/FCT

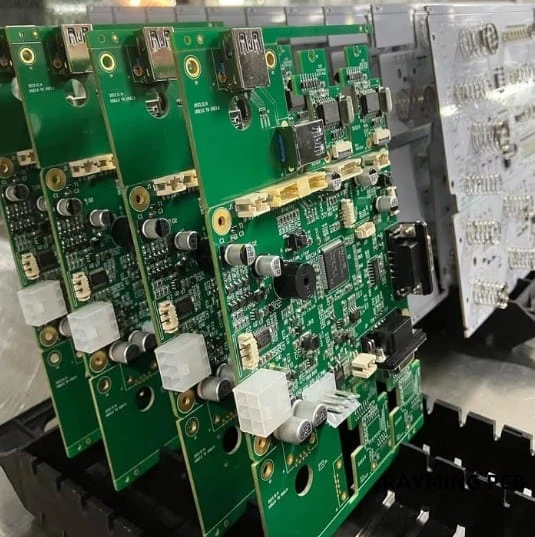

Seven SMT lines, nitrogen reflow, and selective/wave solder cells run side by side with inline SPI/AOI/AXI and ICT/FCT planning so prototypes, pilots, and steady-state lots share the same traveler and guardrails.

Tooling, feeders, and SPC keep CpK ≥1.33 even when ECOs land mid-shift.

Dedicated expedite + high-speed lanes with mirrored tooling.

Vacuum pickup, warpage support, and selective solder for odd-form.

Offline kitting + feeder banks keep mix flexible without downtime.

COVERAGE

We own stencil, placement, reflow, selective solder, inspection, and ICT/FCT so every gate rolls into the next without waiting on another supplier.

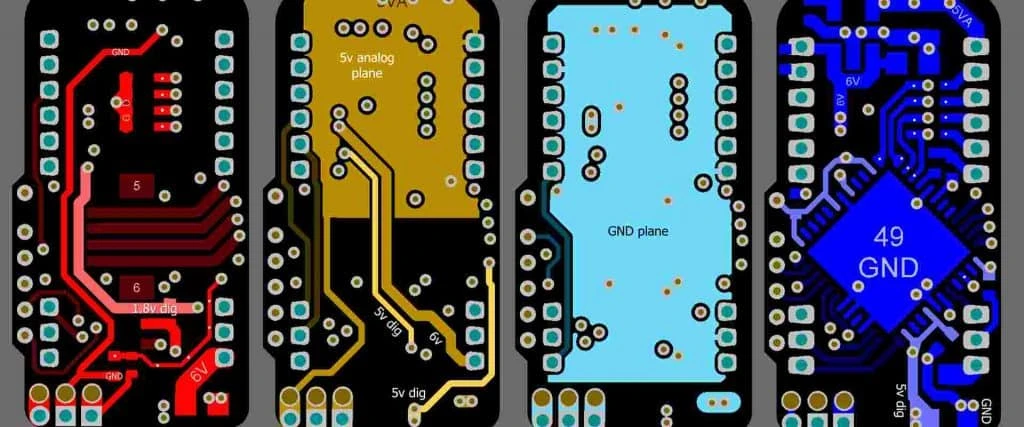

Stencil & paste engineering

Area-ratio checks, step/nano coatings, and paste qualification lock print windows.

SMT placement

Seven SMT lines place 01005–100×90 mm with ±25 µm accuracy and CpK ≥1.33.

Selective & wave solder

Nitrogen selective solder, wave with titanium fingers, and custom fixtures protect wetting.

Inspection & test

3D SPI/AOI, sample AXI, ionic reports, flying probe, ICT/FCT, and boundary-scan.

PLAYBOOK

Clear gates pair engineering data with production execution so every revision ships with proof.

DFX & tooling

Review stencils, panels, fixtures, and selective solder pallets.

Line setup

Offline kitting, feeder prep, and recipe lock before boards arrive.

SMT execution

Dual-lane SMT lines run 100% SPI/AOI with CpK monitoring.

Selective & wave

Nitrogen selective/wave solder with thermal profiling and AOI checks.

Inspection & ICT/FCT

AXI, ionic, flying probe, ICT/FCT, and boundary-scan log into MES.

PORTFOLIO

Builds spanning automotive control, medical diagnostics, industrial drives, and compute hardware.

CAPABILITIES

Placement, solder, inspection, and test infrastructure sized for complex builds.

ESD, humidity, and nitrogen-controlled zones with MES travelers guiding material flow.

QUALITY

Inline inspection, solder control, and test coverage keep FPY at 98–99%.

SPI, placement, reflow, and selective solder SPC with CpK alerts.

100% SPI/AOI plus sample AXI and post-wave AOI tied to MES.

Flying probe, ICT/FCT, and boundary-scan lock in coverage before ramp.

ECU/inverter boards with selective solder, hi-pot, and PPAP-ready QA.

ISO 13485 builds with cleanliness reports and traceable solder recipes.

Rugged controllers with press-fit, conformal coat, and vibration test.

High-layer, high-power boards with thermal interface prep and RF calibration.

Everything you need to know about HDI PCB technology

Upload your files to receive a build, changeover, and coverage plan.