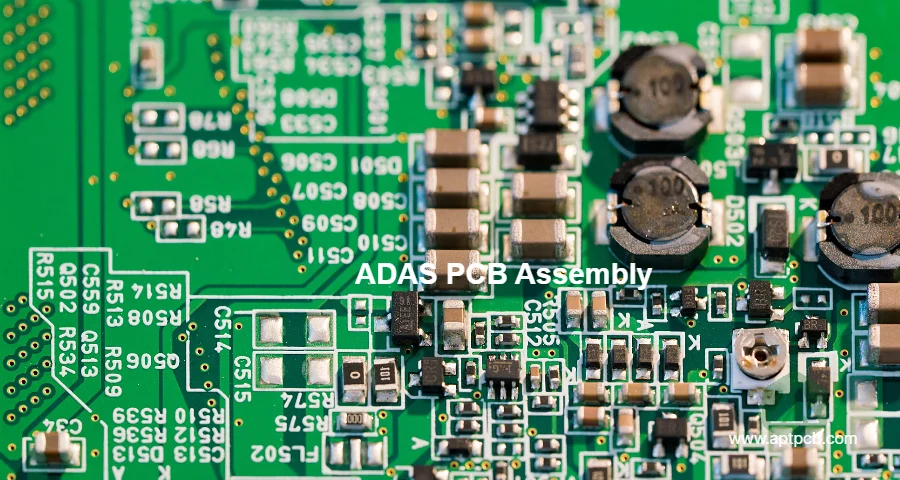

ADAS PCB assemblies implement sensor fusion platforms processing camera, radar, ultrasonic, and lidar data executing collision warning, automatic emergency braking, lane keeping assist, adaptive cruise control, and parking assistance requiring real-time processing <100ms latency, ISO 26262 ASIL-B/D functional safety, and validated reliability across passenger vehicles, commercial trucks, and L2+ autonomous platforms demanding fail-safe operation supporting safety-critical functions through 10-15 year vehicle lifecycles with zero-tolerance for safety-related failures.

At APTPCB, we deliver specialized ADAS assembly services implementing safety-qualified processes, sensor integration, and real-time platforms with turnkey assembly capabilities supporting diverse ADAS features and autonomy levels.

Achieving ISO 26262 Functional Safety Compliance

ADAS safety functions require ISO 26262 compliance achieving ASIL-B (warning systems) through ASIL-D (active intervention systems) through safety analysis, architectural safety mechanisms, and validation activities demonstrating systematic and random hardware failure targets. Functional safety challenges include implementing comprehensive diagnostics achieving >90% coverage, validating fail-safe transitions to safe states, and demonstrating safety throughout development lifecycle. Inadequate safety implementation prevents certification, creates liability exposure, or results in actual safety incidents — significantly impacting product viability, legal compliance, and market introduction as ADAS adoption accelerates and regulatory requirements strengthen.

At APTPCB, our assembly implements ISO 26262 compliant processes achieving ASIL-B through ASIL-D ratings for safety-critical ADAS functions.

Functional Safety Implementation

- Safety Architecture Design: Redundant sensors, processing paths, and actuator control enabling fault detection and safe-state transitions with special PCB manufacturing precision.

- Comprehensive Diagnostics: Self-test routines, plausibility checks, and hardware monitors achieving >90% diagnostic coverage per ASIL requirements detecting component failures before unsafe conditions.

- Fail-Safe Transitions: Validated degradation modes enabling controlled transitions to minimal risk conditions during detected faults preventing accidents.

- Development Process Compliance: ISO 26262 V-model implementation with safety requirements traceability, FMEA analysis, and safety validation activities.

- Systematic Capability: Manufacturing process controls preventing systematic defects and achieving required random hardware failure rates <10 FIT for ASIL-D.

- Independent Safety Assessment: Third-party evaluation validating safety compliance and achieving certification for safety-critical ADAS functions.

Safety-Critical Manufacturing

Through ISO 26262 expertise, safety-qualified processes, and comprehensive validation coordinated with quality management systems, APTPCB enables ADAS manufacturers achieving functional safety certification supporting deployment of life-saving collision avoidance and automated driving features.

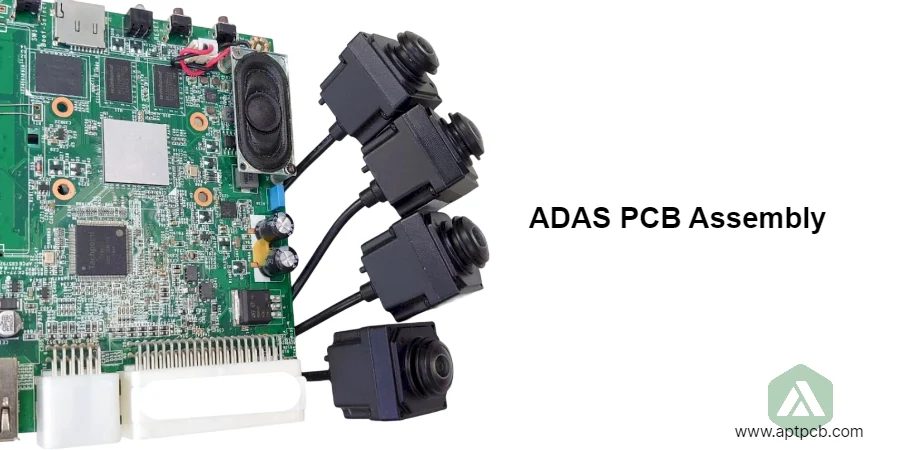

Implementing Camera-Based Vision Processing

Forward-facing cameras detect lane markings, traffic signs, pedestrians, and vehicles requiring image sensors (1-8MP), real-time image processing, object detection algorithms, and automotive-qualified optics surviving temperature extremes and vibration. Camera processing challenges include maintaining detection accuracy in challenging conditions (rain, fog, glare), achieving <50ms processing latency for real-time response, and validating detection performance across diverse scenarios. Inadequate camera implementation causes missed detections creating safety gaps, false positives causing unnecessary warnings, or environmental sensitivity limiting functionality — significantly impacting ADAS reliability and customer trust in automated features.

At APTPCB, our manufacturing supports automotive camera systems achieving reliable vision-based detection across operating conditions.

Camera Vision Implementation

- High-Performance ISP: Image signal processors optimizing dynamic range, noise reduction, and color accuracy enabling detection algorithms with ICT test validation.

- Real-Time Object Detection: Neural network accelerators executing CNN models detecting pedestrians, vehicles, and obstacles with >95% accuracy at 30-60fps.

- Multi-Camera Integration: Surround view systems combining 4-8 cameras providing 360° environmental awareness for parking assistance and blind spot monitoring.

- HDR Image Processing: High dynamic range processing maintaining visibility in high-contrast scenes (tunnels, shadows, sunset) where traditional cameras fail.

- Automotive Optical Systems: Temperature-stabilized lenses and sealed housings maintaining focus and preventing contamination across automotive environmental extremes.

- Camera Calibration: Factory calibration and in-field auto-calibration maintaining detection accuracy despite installation variations and long-term alignment drift.

Reliable Vision Systems

Through advanced image processing, validated detection algorithms, and automotive-qualified optics coordinated with manufacturing expertise, APTPCB enables camera-based ADAS achieving reliable object detection supporting lane keeping, collision warning, and traffic sign recognition across diverse driving conditions.

Integrating Radar for All-Weather Detection

Automotive radar provides reliable object detection in fog, rain, and darkness using 77GHz mmWave technology detecting vehicles, pedestrians, and obstacles at 1-250m range requiring RF front-end design, signal processing, and interference mitigation. Radar integration challenges include maintaining detection sensitivity despite weather attenuation, rejecting interference from other radars in traffic, and achieving accurate velocity measurement through Doppler processing. Inadequate radar implementation reduces detection range limiting functionality, causes false detections from interference, or misses slow-moving objects creating safety gaps — significantly impacting ADAS reliability and all-weather capability as radar becomes essential sensor for collision avoidance and adaptive cruise control.

At APTPCB, our assembly supports 77GHz radar integration achieving reliable all-weather detection and accurate tracking.

Radar Integration Implementation

- 77GHz RF Front-End: MMIC transceiver integration with precision antenna arrays achieving >150m detection range with 1m range resolution through flying probe testing validation.

- FMCW Signal Processing: Fast chirp modulation and FFT processing providing simultaneous range and velocity measurement enabling accurate target tracking.

- Multi-Target Tracking: Kalman filtering and data association algorithms tracking dozens of objects simultaneously maintaining target continuity despite occlusion.

- Interference Mitigation: Frequency diversity and adaptive filtering rejecting interference from other radars maintaining detection performance in dense traffic.

- Angular Resolution: MIMO virtual array techniques achieving 1-2° azimuth resolution enabling lane assignment and cut-in detection.

- Automotive Environmental Validation: Testing across temperature, vibration, and EMC requirements ensuring reliable operation despite automotive electrical noise.

All-Weather Sensing Capability

Through 77GHz radar expertise, advanced signal processing, and automotive validation coordinated with assembly processes, APTPCB enables ADAS platforms achieving reliable detection in all weather conditions supporting adaptive cruise control, collision avoidance, and automated emergency braking.

Executing Real-Time Sensor Fusion

Sensor fusion combines camera, radar, ultrasonic, and optional lidar data providing comprehensive environmental understanding more robust than individual sensors through Kalman filtering, Bayesian estimation, and machine learning requiring high-performance processing, deterministic latency, and validated fusion algorithms. Fusion challenges include managing sensor measurement uncertainties, resolving conflicting detections, and maintaining real-time performance processing dozens of simultaneous objects. Inadequate fusion implementation causes delayed or inconsistent detections, missed objects from sensor gaps, or computational bottlenecks degrading performance — significantly impacting ADAS functionality and safety as fusion quality determines overall system capability.

At APTPCB, our manufacturing supports high-performance sensor fusion platforms achieving comprehensive environmental awareness.

Sensor Fusion Implementation

- High-Performance Processing: Automotive-qualified multi-core processors or AI accelerators executing fusion algorithms within <50ms latency budgets.

- Multi-Sensor Calibration: Factory and in-field calibration aligning sensor coordinate frames maintaining fusion accuracy despite installation tolerances.

- Uncertainty Management: Kalman and particle filters propagating measurement uncertainties providing probabilistic environmental representation.

- Conflict Resolution: Voting and confidence-based arbitration resolving contradictory sensor detections maximizing detection rate while minimizing false positives.

- Temporal Consistency: Object tracking maintaining identity and trajectory predictions across sensor updates enabling predictive ADAS functions.

- Validation Testing: Scenario-based testing across diverse conditions validating fusion performance and achieving certification requirements.

Robust Environmental Understanding

Through sophisticated sensor fusion, validated algorithms, and high-performance processing coordinated with automotive manufacturing, APTPCB enables ADAS platforms achieving comprehensive environmental awareness supporting L2+ automated driving features.

Supporting Diverse ADAS Features and Functions

ADAS encompasses diverse functions from entry-level forward collision warning through L2+ hands-free highway driving requiring scalable platforms, flexible sensor configurations, and validated feature implementations. Feature diversity challenges include managing complexity across ADAS tiers, validating each feature variation, and supporting regional regulatory requirements. Inadequate platform flexibility limits market coverage, increases development costs, or delays regional launches — significantly impacting business efficiency and competitive positioning as ADAS adoption expands across vehicle segments.

At APTPCB, we support flexible ADAS manufacturing accommodating diverse feature sets and configurations across vehicle platforms.

ADAS Feature Support

Entry-Level ADAS

- Forward collision warning and automatic emergency braking using single camera or radar.

- Lane departure warning and lane keeping assist using camera lane detection.

- Blind spot monitoring and rear cross-traffic alert using radar sensors.

- Parking assistance with ultrasonic sensors providing proximity warnings.

Advanced L2+ Systems

- Adaptive cruise control with stop-and-go capability in traffic.

- Lane centering maintaining vehicle position during highway driving.

- Highway pilot enabling hands-free driving on controlled access roads.

- Traffic jam assist combining ACC and lane centering at low speeds.

Through comprehensive ADAS manufacturing and feature validation coordinated with SPI inspection quality control, APTPCB enables ADAS platforms spanning entry safety features through advanced L2+ automated driving across diverse vehicle segments and markets worldwide.