Contents

- Highlights

- What Is Aes/ebu PCB? (Scope & Boundaries)

- Metrics That Matter (How to Evaluate It)

- How to Choose (Material & Design Selection)

- Implementation Checkpoints (from Design to Fab)

- Common Mistakes (and How to Avoid Them)

- Supplier Qualification Checklist: How to Vet Your Fab

- Glossary

- 6 Essential Rules for Aes/ebu PCB (Cheat Sheet)

- FAQ

- Request a Quote / DFM Review for Aes/ebu PCB

- Conclusion

In the world of professional audio broadcasting and studio engineering, signal integrity is not a luxury—it is the baseline requirement. A single pop, click, or jitter-induced artifact can ruin a master recording or a live broadcast feed. While much attention is paid to the cables and connectors (XLR), the physical foundation of digital audio transmission lies in the AES/EBU PCB.

Designing and manufacturing a Printed Circuit Board for the AES3 standard (commonly known as AES/EBU) requires a shift in mindset from standard analog audio layouts. It is not just about connecting point A to point B; it is about maintaining a precise transmission line environment to prevent signal reflection and data loss. At APTPCB, we see many designs fail not because of bad schematics, but because of poor stackup planning and lack of impedance control during fabrication.

This guide serves as your definitive engineering resource. We will move beyond the basic definitions and dive into the manufacturing realities, material selections, and design-for-manufacturing (DFM) protocols necessary to produce flawless AES/EBU hardware.

Highlights

- The 110Ω Imperative: Why characteristic impedance is the single most critical metric in AES/EBU fabrication.

- Material Selection: Why you don't always need expensive Rogers materials, but you do need consistent FR4.

- Topology & Layout: Best practices for differential pairs and termination to minimize jitter.

- Manufacturing Checkpoints: How to validate your board using TDR (Time Domain Reflectometry) before assembly.

- Failure Analysis: Common reasons for AES3 signal degradation and how to prevent them at the Gerber stage.

What Is Aes/ebu PCB? (Scope & Boundaries)

An AES/EBU PCB is a circuit board designed to carry digital audio signals according to the AES3 standard (established by the Audio Engineering Society and the European Broadcasting Union). Unlike analog audio, which relies on voltage amplitude to represent sound waves, AES3 transmits digital data (2 channels of PCM audio) over a balanced twisted pair.

The defining characteristic of an AES/EBU PCB is its requirement for a 110-ohm (Ω) characteristic impedance.

While the frequency content of AES3 is relatively low compared to modern high-speed data (typically 3 MHz to 6 MHz for standard sample rates, pushing higher for 192kHz audio), the signal is highly susceptible to impedance mismatches. If the PCB traces do not match the 110Ω impedance of the cables and receiver transformers, signal energy is reflected back to the source. This creates standing waves and "jitter"—timing errors that degrade the audio quality, causing a loss of stereo imaging or audible distortion.

Therefore, an AES/EBU PCB is effectively a Controlled Impedance PCB. It requires precise calculation of trace width, spacing, and dielectric height.

Tech Feature → Buyer Impact

| Technical Feature / Decision | Direct Impact (Yield/Reliability) |

|---|---|

| 110Ω Impedance Control (±10%) | Prevents signal reflections (Return Loss). Ensures the digital "eye pattern" remains open for error-free audio decoding. |

| Tightly Coupled Differential Pairs | Maximizes Common Mode Rejection Ratio (CMRR). Critical for noise immunity in electrically noisy studio environments. |

| Continuous Reference Planes | Reduces EMI radiation and prevents "ground bounce," which can induce jitter in the digital audio stream. |

| Backdrilling (for thick backplanes) | Removes via stubs that act as antennas/filters, preserving signal integrity on complex, high-layer-count broadcast consoles. |

Metrics That Matter (How to Evaluate It)

When evaluating the quality of an AES/EBU PCB design or a fabricated prototype, specific metrics must be analyzed. Unlike general-purpose boards where connectivity is the only goal, AES3 boards must meet physical physics criteria.

| Metric | Target Value | Why It Matters |

|---|---|---|

| Differential Impedance ($Z_{diff}$) | 110Ω ± 10% | This is the standard. Deviations cause reflections (Return Loss), leading to data packet errors or jitter. |

| Trace Width Tolerance | ± 10-15% | Manufacturing etching variations affect impedance. Tighter tolerance requires higher-tier fabrication capability. |

| Dielectric Constant ($D_k$) | Consistent (e.g., 4.2) | Variations in the core or prepreg material $D_k$ will shift the impedance away from 110Ω. |

| Intra-Pair Skew | < 5-10 mils | The length difference between the Positive (+) and Negative (-) trace. High skew converts differential signals into common-mode noise. |

| Return Loss | > 15dB | A measure of how much signal is reflected. Higher is better (meaning less reflection). |

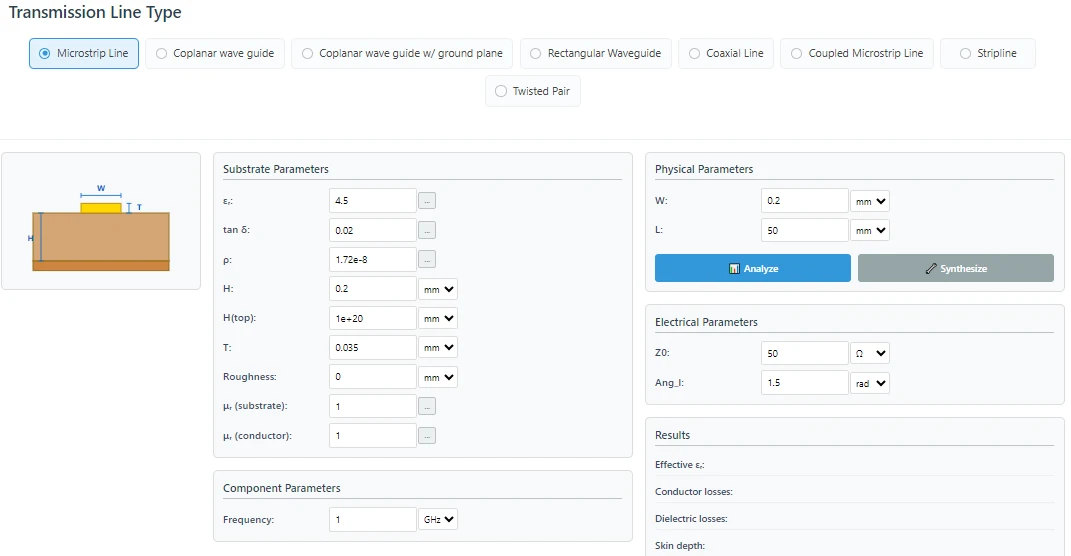

For engineers utilizing our Impedance Calculator, it is vital to input the exact stackup data provided by the fab house, as theoretical calculations often differ from the reality of pressed prepreg thickness.

How to Choose (Material & Design Selection)

Selecting the right materials and design parameters is the first step toward a successful AES/EBU deployment.

1. Material Selection: FR4 vs. High-Speed Materials

A common misconception is that digital audio requires exotic materials like Rogers or Teflon.

- Reality: The fundamental frequency of AES3 is roughly 3-6 MHz. Standard FR4 (High-Tg preferred for assembly reliability) is perfectly adequate for signal integrity at these frequencies.

- The Caveat: The consistency of the FR4 matters. You need a laminate with a stable Dielectric Constant ($D_k$) and consistent weave. For extremely long runs or high-density broadcast routers, "Spread Glass" FR4 can help minimize skew caused by the fiber weave effect.

- Recommendation: Use standard FR4 PCB material but specify impedance control in your fabrication notes. This forces the manufacturer to verify the stackup.

2. Stackup Design

The distance between the signal layer and the reference plane (ground) dictates the trace width needed for 110Ω.

- Thinner Dielectrics: Require narrower traces to maintain 110Ω.

- Thicker Dielectrics: Allow for wider traces.

- Tip: 110Ω is a relatively high impedance. On standard 1.6mm boards, this often requires slightly wider spacing between the differential pair or a larger distance to the ground plane. Ensure your PCB Stackup allows for manufacturable trace widths (usually >4 mils).

3. Connector Layout

AES/EBU usually interfaces via XLR or BNC. The footprint of these connectors introduces a massive impedance discontinuity.

- Design Tip: Keep the traces from the connector pins to the transformer/receiver chip as short as possible.

- Grounding: Ensure the chassis ground (XLR shell) and signal ground are managed correctly to prevent ground loops, a common plague in audio.

Implementation Checkpoints (from Design to Fab)

To ensure your AES/EBU PCB performs as intended, follow this process roadmap. These are the checkpoints we use at APTPCB during our DFM reviews.

Implementation Roadmap

From Concept to Production

Verify the 110Ω termination resistor is placed as close to the receiver IC as possible. Ensure isolation transformers are specified to break ground loops.

Coordinate with the fab house *before* routing. Determine the exact trace width/spacing (e.g., 5mil/6mil) required to hit 110Ω diff impedance on the specific material stock.

Route AES signals as differential pairs. Ensure they run over a solid, unbroken ground plane. Do not cross split planes, as this destroys impedance control.

Request "Impedance Coupons" on the panel rails. The manufacturer must perform TDR testing to verify the actual impedance is within ±10% of 110Ω.

Common Mistakes (and How to Avoid Them)

Even experienced engineers make errors when transitioning from analog to digital audio PCB design.

1. Ignoring the Return Path

The most common failure is routing the AES differential pair over a split in the ground plane (e.g., crossing from digital ground to analog ground).

- Consequence: The return current is forced to take a long loop, creating a massive inductance loop area. This ruins impedance and turns the trace into an antenna that radiates EMI.

- Fix: Always route high-speed digital audio over a solid, continuous reference plane.

2. "Eyeballing" Trace Widths

Using a standard 50Ω single-ended trace width for a 110Ω differential pair will fail.

- Consequence: Severe signal reflection.

- Fix: Use a field solver or our Impedance Calculator to calculate the specific differential geometry.

3. Poor Connector Placement

Placing the AES receiver chip far from the XLR connector creates long transmission lines.

- Consequence: Increased susceptibility to external noise and greater chance of impedance mismatch.

- Fix: Place I/O components near the edge of the board.

Supplier Qualification Checklist: How to Vet Your Fab

Not all PCB manufacturers understand the nuances of digital audio. Use this checklist when selecting a partner for your AES/EBU projects.

- Do you perform TDR (Time Domain Reflectometry) testing on every batch? (Essential for verifying 110Ω).

- What is your standard etching tolerance? (Should be ±10% or better for impedance control).

- Can you provide a custom stackup report before production? (You need to verify layer thickness).

- Do you support "Spread Glass" FR4 options? (Useful for high-end professional audio gear).

- How do you handle impedance coupons? (They should be on the panel rails for verification).

- Do you offer cross-section analysis? (To verify plating thickness and dielectric height).

At APTPCB, these checks are standard procedure for our High Frequency PCB and digital audio clients.

Glossary

AES3 (AES/EBU): A standard for the exchange of digital audio signals between professional audio devices. It carries two channels of PCM audio.

Characteristic Impedance ($Z_0$): The opposition a transmission line presents to the flow of current. For AES3, the differential impedance must be 110Ω.

Differential Pair: Two complementary signals (positive and negative) sent on two separate traces. The receiver detects the difference between them, canceling out common-mode noise.

Jitter: The deviation in or displacement of some aspect of the pulses in a high-frequency digital signal. In audio, this translates to distortion and loss of fidelity.

TDR (Time Domain Reflectometry): A measurement technique used to determine the characteristic impedance of a PCB trace by sending a pulse and measuring the reflection.

6 Essential Rules for Aes/ebu PCB (Cheat Sheet)

| Golden Rule | Why It Matters | Implementation Key |

|---|---|---|

| Target 110Ω Exactly | Matches standard cables/transformers. | Calculate trace width/spacing for 110Ω Diff. |

| Continuous Ground | Preserves return path and impedance. | Never route over split planes. |

| Minimize Stubs | Stubs cause reflections. | Daisy-chain routing; avoid T-junctions. |

| Tight Coupling | Improves noise rejection (CMRR). | Keep P and N traces close together. |

| Length Matching | Prevents mode conversion. | Match lengths within 5-10 mils. |

| Verify with TDR | Ensures manufacturing accuracy. | Specify "Impedance Control" in Fab Notes. |

FAQ

Q: Can I use standard FR4 for AES/EBU PCBs?

A: Yes, standard FR4 is sufficient for the frequency range of AES3 (approx. 6 MHz). However, you must ensure the manufacturer can hold tight tolerances on trace width and dielectric thickness to maintain the 110Ω impedance.

Q: What is the difference between AES/EBU and S/PDIF PCB design?

A: While the data protocol is similar, the electrical interface differs. AES/EBU is balanced (differential) with 110Ω impedance and higher voltage levels (2-7V). S/PDIF is unbalanced (single-ended) with 75Ω impedance and lower voltage (0.5V). You cannot mix the routing strategies; S/PDIF requires 75Ω single-ended traces.

Q: How do I calculate the trace width for 110Ω?

A: You cannot guess this. You must use an impedance calculator or field solver. You need to know the Dielectric Constant ($D_k$) of the material, the distance to the reference plane (H), the trace thickness (T), and the trace spacing (S).

Q: Does the connector footprint affect impedance?

A: Yes. The pads of an XLR or transformer are much wider than the traces, creating a capacitive discontinuity. To mitigate this, you can remove the ground plane directly underneath the component pads (reference plane voiding) to increase inductance and balance the impedance, though this is an advanced technique usually reserved for higher frequencies.

Q: Why is my AES signal failing over long cable runs?

A: If the PCB impedance is not 110Ω, reflections occur at the connector. Over short runs, this might be invisible. Over long runs, the cable attenuation combined with the PCB's return loss degrades the signal eye pattern enough to cause "unlock" errors at the receiver.

Q: Do I need to backdrill vias for AES/EBU?

A: Generally, no. The frequencies are low enough that standard via stubs do not cause significant resonance. However, on very thick backplanes (e.g., >3mm) used in large broadcast routers, backdrilling may be beneficial to preserve maximum signal integrity.

Request a Quote / DFM Review for Aes/ebu PCB

Ready to move your audio design from prototype to production? At APTPCB, we specialize in controlled impedance boards for the professional audio industry.

To get an accurate quote and free DFM review, please send:

- Gerber Files: (RS-274X format preferred).

- Stackup Request: Specify your desired layer count and overall thickness (e.g., 4-layer, 1.6mm).

- Impedance Requirements: Clearly state "110Ω Differential on Layer X".

- Material Preference: Standard FR4 or specific brand (Isola/Rogers) if required.

- Quantity: Prototype or Mass Production volume.

Conclusion

Designing an AES/EBU PCB is an exercise in precision. It bridges the gap between analog audio layout and high-speed digital design. By respecting the 110Ω impedance requirement, maintaining continuous return paths, and partnering with a manufacturer capable of TDR verification, you ensure that the audio leaving your device is exactly as pure as the audio that entered it.

Don't let your PCB be the weak link in the signal chain. Whether you are building a boutique AD/DA converter or a massive broadcast console, APTPCB has the manufacturing capabilities to deliver the performance your audio demands.