Aircraft Entertainment quick answer (30 seconds)

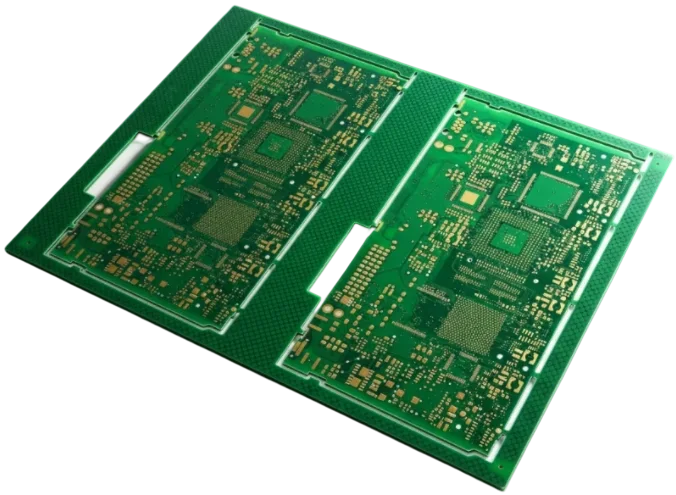

Designing hardware for Aircraft Entertainment (In-Flight Entertainment or IFE) requires balancing high-speed data transmission with strict aerospace safety standards. Unlike consumer electronics, these systems must endure rapid decompression, constant vibration, and rigorous flammability tests while delivering 4K video streams.

- Standard Compliance: Must meet RTCA/DO-160 for environmental conditions and FAR 25.853 for flammability.

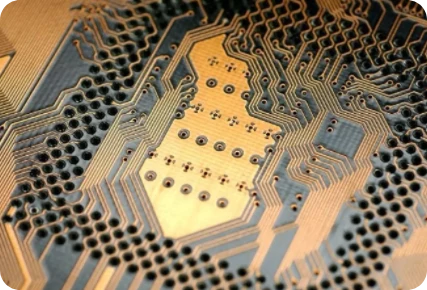

- Signal Integrity: High-speed interfaces (HDMI, Ethernet, USB-C) require controlled impedance (typically 90Ω or 100Ω ±10%) to prevent video artifacts.

- Thermal Management: Seat-back units have zero airflow; PCBs must utilize high-Tg materials (>170°C) and efficient thermal via structures.

- Vibration Resistance: Connectors and heavy components (capacitors/inductors) require bonding or underfill to survive flight turbulence.

- EMI/EMC: Strict shielding is mandatory to prevent interference with avionics; use multi-layer stackups with dedicated ground planes.

- Reliability: IPC Class 2 is the baseline, but IPC Class 3 is recommended for core servers and power distribution units to ensure longevity.

When Aircraft Entertainment applies (and when it doesn’t)

Aircraft Entertainment systems are distinct from mission-critical avionics, yet they share the same physical environment. Understanding where IFE standards apply helps optimize cost without compromising safety.

When Aircraft Entertainment standards apply:

- Seat-Back Display Units (SDU): Designing PCBs for touchscreens embedded in passenger seats.

- Seat Electronic Boxes (SEB): Under-seat power and data distribution hubs requiring robust thermal design.

- Overhead Video Systems: Retractable screens that must operate reliably after thousands of mechanical cycles.

- Wireless Access Points (WAP): Cabin Wi-Fi hardware requiring high-frequency RF materials.

- Passenger Control Units (PCU): Remote controls and armrest interfaces exposed to liquid spills and heavy physical wear.

When they do not apply (or require different standards):

- Flight Control Systems: Primary avionics (fly-by-wire) require higher redundancy levels (DAL A/B) than entertainment systems (DAL D/E).

- Engine Monitoring: Sensors located in unpressurized or high-heat engine zones require ceramic or metal-core substrates, not standard IFE FR-4.

- Ground Support Equipment: Test rigs used in hangars do not need to meet weight or altitude restrictions.

- Cockpit Primary Flight Displays: While similar in technology, these fall under critical Aircraft Instrument regulations rather than passenger entertainment.

Aircraft Entertainment rules and specifications (key parameters and limits)

The following table outlines the critical design rules for manufacturing reliable IFE hardware. These parameters ensure the Aircraft Entertainment system survives the transition from the lab to the aircraft cabin.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Base Material Tg | > 170°C (High Tg FR-4) | Prevents delamination during high-temp assembly and operation in enclosed seat boxes. | DSC (Differential Scanning Calorimetry) | Pad lifting or barrel cracks during soldering. |

| Impedance Control | 90Ω / 100Ω ±10% | Essential for HDMI, USB, and Ethernet signals used in media streaming. | TDR (Time Domain Reflectometry) | Video dropouts, pixelation, or complete signal loss. |

| Copper Weight | 1 oz (inner) / 2 oz (outer) | Handles power distribution for USB charging ports without excessive voltage drop. | Microsection analysis | Overheating traces, voltage sag at user ports. |

| Surface Finish | ENIG (Electroless Nickel Immersion Gold) | Provides flat surface for fine-pitch BGAs and excellent corrosion resistance. | X-Ray Fluorescence (XRF) | Poor solder joints on high-pin-count video processors. |

| Flammability | UL94 V-0 / FAR 25.853 | Mandatory safety requirement to prevent fire propagation in the cabin. | Vertical Burn Test | Certification failure; hardware grounded. |

| Via Reliability | Aspect Ratio < 10:1 | Ensures plating solution penetrates vias for solid electrical connection. | Cross-section inspection | Open circuits after thermal cycling or vibration. |

| Conformal Coating | Acrylic or Urethane | Protects against condensation (fuselage sweating) and spilled drinks. | UV light inspection | Corrosion and short circuits from moisture. |

| Component Height | < 5mm (for seat backs) | Space inside slimline seats is extremely limited; prevents crushing. | 3D CAD interference check | Mechanical interference; screen cracking. |

| EMI Shielding | 360° termination / Cans | Prevents IFE noise from interfering with pilot radios. | EMC Chamber Testing | Failed DO-160 emissions test; redesign required. |

| Solder Mask | Matte Green or Black | Matte finish reduces glare during assembly inspection and reduces eye fatigue. | Visual inspection | Glossy mask may cause reflection errors in AOI. |

| Cleanliness | < 1.56 µg/cm² NaCl eq. | Ionic residues cause dendritic growth under humidity. | ROSE Test (Ionic Contamination) | Intermittent shorts over time. |

| Blind/Buried Vias | HDI 1+N+1 or 2+N+2 | Required for routing high-density signals on compact Aircraft Display PCB units. | Layer stackup verification | Impossible to route FPGA/CPU; increased board size. |

Aircraft Entertainment implementation steps (process checkpoints)

Implementing a new Aircraft Entertainment system involves a rigorous workflow to ensure Design for Manufacturing (DFM) and Design for Assembly (DFA) compliance.

Requirement Definition & Stackup Selection

- Action: Define the layer stackup based on signal speed (e.g., 12-layer HDI for 4K streaming).

- Parameter: Dielectric constant (Dk) stability up to 10 GHz.

- Check: Confirm material availability with APTPCB (APTPCB PCB Factory) to avoid lead time delays.

Schematic Capture & Component Selection

- Action: Select automotive or aerospace-grade components with wide temperature ranges (-40°C to +85°C).

- Parameter: Component derating (power/voltage) by 20-30%.

- Check: Verify all ICs have available IBIS models for signal simulation.

PCB Layout & Thermal Simulation

- Action: Place high-heat components (processors, power regulators) away from sensitive analog circuits.

- Parameter: Junction temperature (Tj) < 125°C under max load.

- Check: Run thermal simulation assuming zero airflow (conduction cooling only).

Signal Integrity & EMI Analysis

- Action: Route high-speed differential pairs first; stitch ground vias every 5mm along the path.

- Parameter: Crosstalk < -50dB.

- Check: Simulate eye diagrams for HDMI/PCIe interfaces.

DFM Review & Prototype Fabrication

- Action: Submit Gerber files for a comprehensive DFM check to identify acid traps or slivers.

- Parameter: Min trace/space 3/3 mil for HDI designs.

- Check: Confirm impedance coupons are included in the manufacturing panel.

First Article Inspection (FAI)

- Action: Assemble the first 5-10 units and perform X-ray inspection on BGAs.

- Parameter: Void percentage < 25% in BGA solder balls.

- Check: Validate physical dimensions against the mechanical housing drawing.

Environmental Stress Screening (ESS)

- Action: Subject the prototype to random vibration and thermal cycling.

- Parameter: 6 Grms vibration profile (DO-160 Curve C).

- Check: Monitor video output continuously; no flickering allowed.

Final Certification & Production

- Action: Lock the design revision and move to mass production.

- Parameter: Yield rate > 98%.

- Check: Archive all manufacturing data for traceability (required for 10+ years).

Aircraft Entertainment troubleshooting (failure modes and fixes)

Failures in Aircraft Entertainment systems often manifest as intermittent glitches due to the harsh operating environment. Systematic troubleshooting is required to isolate the root cause.

Symptom: Intermittent Video Signal (Flickering)

- Cause: Impedance mismatch causing signal reflection, or cracked solder joints from vibration.

- Check: Perform TDR analysis on the PCB traces; X-ray BGA components for hairline cracks.

- Fix: Adjust trace width for correct impedance; apply underfill to large BGA packages.

- Prevention: Use Rigid-Flex PCB technology to eliminate connectors that are prone to vibration failure.

Symptom: System Overheating / Shutdown

- Cause: Inadequate thermal dissipation in the seat-back enclosure; blocked thermal vias.

- Check: Measure case temperature with thermocouples; inspect via plating quality.

- Fix: Increase copper weight on inner planes to spread heat; add thermal pads to chassis.

- Prevention: Use Metal Core PCBs for LED backlight drivers to improve heat transfer.

Symptom: Audio Buzz or Hum

- Cause: Ground loop or EMI coupling from power lines (400Hz aircraft power).

- Check: Inspect ground partitioning; look for analog signals routed near switch-mode power supplies.

- Fix: Improve ground plane stitching; add ferrite beads to power inputs.

- Prevention: Implement strict separation between Aircraft Power PCB sections and sensitive audio circuits.

Symptom: Touchscreen Unresponsiveness

- Cause: EMI noise affecting capacitive sensing, or flex cable damage.

- Check: Monitor noise floor on sensor lines; inspect flex tails for tears.

- Fix: Add shielding layers to the flex tail; adjust sensor threshold firmware.

- Prevention: Reinforce flex cables with stiffeners at connection points.

Symptom: Corrosion on Connectors

- Cause: Condensation accumulation or liquid ingress (spilled drinks).

- Check: Visual inspection under magnification for green/white residue.

- Fix: Clean and re-solder; apply thicker conformal coating.

- Prevention: Design housing with drip loops; specify IP67-rated connectors where possible.

Symptom: Radiated Emissions Failure (DO-160)

- Cause: High-frequency noise escaping from board edges.

- Check: Near-field probe scanning to identify "hot spots".

- Fix: Add "via fencing" around the board perimeter; use conductive gasket materials.

- Prevention: Simulate EMC performance during the layout phase.

How to choose Aircraft Entertainment (design decisions and trade-offs)

Selecting the right architecture for Aircraft Entertainment involves trading off weight, cost, and performance.

Rigid vs. Rigid-Flex Architecture

- Rigid PCBs: Lower cost, standard manufacturing. Best for stationary servers or SEBs (Seat Electronic Boxes). Requires cable harnesses which add weight and failure points.

- Rigid-Flex PCBs: Higher initial cost but eliminates connectors and cables. Ideal for Aircraft Display PCB units in articulating arms or tight seat-backs. Reduces weight and improves reliability under vibration.

HDI vs. Standard Through-Hole

- Standard: Sufficient for older audio-only systems or simple reading lights. Lower fabrication cost.

- HDI (High Density Interconnect): Mandatory for modern 4K IFE systems using high-pin-count FPGAs. Increases cost but reduces board size significantly, allowing for slimmer seat profiles.

Material Selection: FR-4 vs. High-Frequency Laminates

- Standard High-Tg FR-4: Suitable for digital logic and power distribution.

- Low-Loss Materials (Rogers/Panasonic): Required for Wi-Fi and satellite communication modules. Mixing these materials (hybrid stackup) optimizes cost while maintaining RF performance.

Centralized vs. Decentralized Power

- Centralized: One large power supply unit (PSU) per seat group. Heavier copper required for distribution; single point of failure.

- Decentralized: Local Point-of-Load (POL) converters on each Aircraft Power PCB. Reduces cabling weight but increases component count and thermal load at the seat.

Aircraft Entertainment FAQ (cost, lead time, common defects, acceptance criteria, system involves a rigorous workflow to ensure Design for Manufacturing (DFM) files)

Q: What is the typical lead time for Aircraft Entertainment PCB prototypes? A: Standard lead time is 10-15 working days for complex HDI or rigid-flex designs. Expedited services can reduce this to 5-7 days, provided materials (like specific High-Tg laminates) are in stock.

Q: How does the cost of IFE PCBs compare to standard consumer electronics? A: IFE PCBs are typically 3-5x more expensive due to stringent requirements: IPC Class 3 fabrication, extensive testing (impedance, cleanliness), and specialized materials. The cost of failure in an aircraft (grounding a plane) far outweighs the component cost.

Q: What are the specific acceptance criteria for Aircraft Entertainment boards? A: Boards must meet IPC-6012 Class 2 or 3. Key criteria include zero open/shorts, strict impedance tolerance (±10%), no exposed copper on edges, and passing ionic contamination tests to prevent corrosion.

Q: Do I need special files for DFM review? A: Yes. Beyond standard Gerbers, you must supply an IPC-356 netlist (for electrical test verification), a detailed stackup drawing specifying dielectric materials, and a drill drawing indicating aspect ratios.

Q: Can APTPCB handle the assembly (PCBA) for these units? A: Yes, we offer full Turnkey Assembly services, including component sourcing, SMT assembly, X-ray inspection for BGAs, and functional testing to simulate aircraft power conditions.

Q: How do you handle obsolescence for long-lifecycle aircraft parts? A: We recommend selecting components with a guaranteed lifecycle of 10+ years. For the PCB itself, we archive tooling and data indefinitely to ensure identical replacement boards can be manufactured years later.

Q: What is the difference between an Aircraft Sensor PCB and an Entertainment PCB? A: An Aircraft Sensor PCB often requires higher temperature resistance and simpler, more robust traces for analog signals. Entertainment PCBs focus on high-speed digital data and complex BGA fanouts.

Q: Why is conformal coating critical for IFE systems? A: Aircraft cabins experience rapid temperature changes causing condensation. Conformal coating prevents moisture from shorting fine-pitch components on the Aircraft Instrument or display boards.

Q: How do you verify impedance for 4K video signals? A: We place test coupons on the manufacturing panel that replicate the actual traces. These coupons are tested using TDR (Time Domain Reflectometry) to ensure they match the design specifications before the boards are shipped.

Q: What documentation is provided for certification? A: We provide a Certificate of Conformance (CoC), material certifications (UL/flammability), microsection reports, and electrical test reports. These are essential for your system's FAA or EASA certification packages.

Resources for Aircraft Entertainment (related pages and tools)

- Aerospace & Defense PCB Solutions: Deep dive into our capabilities for mission-critical avionics and defense electronics.

- HDI PCB Manufacturing: Technical specs for High Density Interconnect boards used in modern IFE servers and displays.

- Rigid-Flex PCB Technology: Learn how to reduce weight and improve reliability in articulating seat-back screens.

- PCB Impedance Calculator: A tool to estimate trace width and spacing for your high-speed video signals.

Aircraft Entertainment glossary (key terms)

| Term | Definition | Context in Aircraft Entertainment |

|---|---|---|

| IFE | In-Flight Entertainment | The overarching system providing audio, video, and connectivity to passengers. |

| LRU | Line Replaceable Unit | A modular component (like a screen or server) designed to be quickly replaced on the tarmac. |

| DO-160 | RTCA/DO-160 | The standard for environmental testing of airborne equipment (vibration, temp, EMI). |

| Seat Pitch | Distance between seats | Determines the maximum thickness allowed for seat-back electronics. |

| Head-End | Server/Content Loader | The central server rack that stores movies and distributes data to seats. |

| SEB | Seat Electronic Box | Under-seat unit handling power and data distribution for a row of seats. |

| IPC Class 3 | High Reliability Standard | Manufacturing standard ensuring continued performance in harsh environments. |

| FAR 25.853 | Flammability Standard | Federal Aviation Regulation governing fire resistance of cabin materials. |

| LVDS | Low-Voltage Differential Signaling | Common interface for driving LCD panels in Aircraft Display PCB units. |

| TDR | Time Domain Reflectometry | Measurement technique used to verify characteristic impedance of PCB traces. |

| V-0 | UL Flammability Rating | Plastic/PCB material stops burning within 10 seconds on a vertical specimen. |

| COTS | Commercial Off-The-Shelf | Using standard commercial parts in aircraft systems to reduce cost (requires careful screening). |

Request a quote for Aircraft Entertainment (system involves a rigorous workflow to ensure Design for Manufacturing (DFM) review + pricing)

Ready to manufacture your IFE hardware? APTPCB provides specialized engineering support to ensure your designs meet aerospace rigor without over-engineering costs.

For the most accurate quote and DFM analysis, please provide:

- Gerber Files (RS-274X): Including all copper layers, soldermask, and silkscreen.

- Fabrication Drawing: Specifying IPC class, material requirements (Tg, halogen-free), and stackup.

- Bill of Materials (BOM): If assembly is required, include manufacturer part numbers.

- Test Requirements: Specify if TDR impedance testing or specific ionic cleanliness levels are needed.

- Volume & Lead Time: Prototype quantity vs. production forecast.

Conclusion (next steps)

Successfully deploying Aircraft Entertainment systems hinges on the reliability of the underlying printed circuit boards. From ensuring signal integrity for 4K streaming to passing rigorous DO-160 vibration and thermal tests, every layer of the PCB stackup matters. By adhering to strict design rules and partnering with a manufacturer experienced in aerospace requirements, engineers can deliver robust, passenger-pleasing systems that withstand the unique challenges of flight.