Why Aluminum LED PCBs are the Backbone of Modern High-Power LED Solutions

APTPCB is an integrated PCB manufacturer and turnkey PCBA provider with broad capabilities across rigid, flex, rigid-flex, HDI and metal-core (aluminum) boards. We design and produce Aluminum LED PCBs when projects demand superior thermal performance, but our engineering and production expertise spans the full PCB portfolio—so you get the right board and process for your electrical, mechanical and cost targets.

Our thermal-management know-how ensures aluminum and other board constructions meet your LED junction-temperature and lifetime goals while remaining manufacturable at scale. If you need a reliable partner to evaluate stackups, optimize thermal paths, and deliver consistent production and assembly, request a technical review and quote — we’ll propose the most cost-effective solution for your application.

Navigating This Guide to Aluminum LED PCBs

This comprehensive guide is structured to provide a deep dive into every aspect of Aluminum LED PCBs. Use the links below to jump to specific topics:

- Understanding the Core Advantage: Aluminum vs. FR-4

- The Anatomy of an Aluminum LED PCB: Layers and Materials

- Design Best Practices for Optimal Thermal Performance

- Manufacturing Aluminum LED PCBs: Process and Quality

- Applications and Future Trends for Aluminum LED PCBs

Understanding the Core Advantage: Aluminum vs. FR-4

The fundamental difference between an Aluminum LED PCB and a standard FR-4 PCB lies in its ability to manage heat. This distinction is critical for any high-power LED application.

The Thermal Challenge with FR-4

Standard FR-4 PCBs are constructed from fiberglass reinforced epoxy resin. While offering excellent electrical insulation and mechanical strength, their thermal conductivity is relatively low (typically around 0.2-0.5 W/m·K). When high-power LEDs generate heat, FR-4 struggles to conduct it away efficiently. This results in:

- Elevated Junction Temperature: The actual temperature at the LED chip junction rises rapidly.

- Reduced Lumen Output: LEDs become less efficient at higher temperatures.

- Color Shift: The emitted light color can change.

- Accelerated Lumen Depreciation: LEDs degrade faster, losing brightness over time.

- Premature Failure: Overheating can cause irreversible damage to the LED or solder joints.

The Aluminum Advantage: Superior Thermal Dissipation

Aluminum LED PCBs directly address this thermal bottleneck by replacing the traditional fiberglass substrate with an aluminum base. The typical thermal conductivity of aluminum is around 200-220 W/m·K – orders of magnitude higher than FR-4. This significant improvement allows heat to be drawn away from the LED much more effectively.

Key Benefits of Aluminum LED PCBs:

- Exceptional Heat Dissipation: Rapidly transfers heat from the LED junction to the aluminum base, which then acts as a heat spreader or connects directly to a heat sink.

- Lower Operating Temperatures: Keeps LEDs running cooler, significantly extending their lifespan and maintaining consistent light output and color.

- Increased Power Density: Enables the use of more powerful LEDs or a greater density of LEDs on a smaller board area.

- Enhanced Reliability: Reduces thermal stress on components and solder joints, leading to a more robust and reliable product.

- Mechanical Stability: Aluminum provides a rigid and durable substrate.

- Electromagnetic Shielding: The aluminum core offers inherent EMI shielding for the circuit layer.

In essence, an Aluminum LED PCB transforms the board from just an electrical conduit into an integral part of the LED's thermal management system, ensuring optimal performance and longevity for high-power lighting solutions.

The Anatomy of an Aluminum LED PCB: Layers and Materials

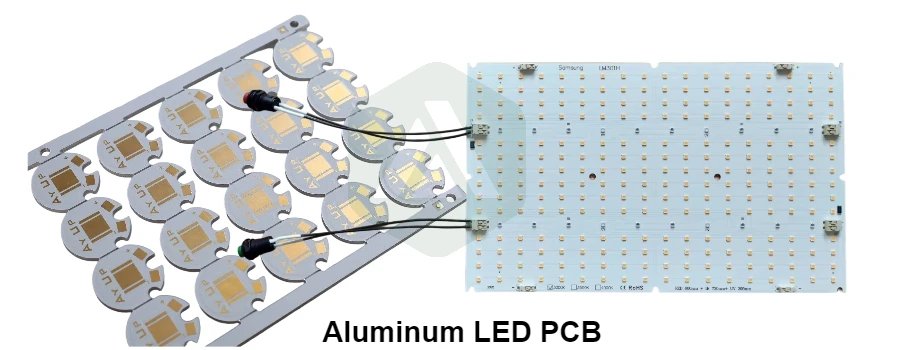

An Aluminum LED PCB, or Aluminum-based Metal Core PCB (MCPCB), is a sophisticated multi-layered structure specifically engineered for thermal efficiency. Understanding its core components and the materials used is crucial for effective design and manufacturing.

Core Layers of an Aluminum LED PCB

Circuit Layer (Copper):

- This is the top layer where the LED components are mounted and the electrical circuits are routed.

- Typically, it's a thin copper foil (1 oz to 3 oz, sometimes thicker for higher current applications).

- The copper provides the electrical pathways and also serves as the initial heat spreader from the LED pads.

Dielectric Layer (Insulation Layer):

- This is the most critical layer after the aluminum base itself. It's a very thin layer (typically 50µm to 150µm) of thermally conductive, electrically insulating material.

- Function: Electrically isolates the copper circuit layer from the conductive aluminum base, preventing short circuits. Simultaneously, it must have extremely high thermal conductivity to efficiently transfer heat from the copper layer to the aluminum base.

- Materials: Often a special epoxy resin mixed with ceramic fillers (like aluminum oxide or boron nitride) to enhance thermal conductivity significantly beyond standard FR-4. Thermal conductivity for these materials can range from 1 W/m·K to over 8 W/m·K.

Aluminum Base Layer:

- This is the metal core, typically an aluminum alloy (e.g., 1100, 5052, 6061).

- Function: Acts as the primary heat sink and mechanical support for the entire structure. Its high thermal conductivity rapidly spreads heat across the board and dissipates it to the ambient environment or an external heat sink.

- Thickness: Commonly 0.8 mm to 3.0 mm, depending on the required mechanical strength and thermal capacity.

Other Potential Layers and Materials

- Solder Mask: A protective layer (often white for reflectivity in lighting applications) covering the copper circuit, leaving pads exposed for soldering.

- Silkscreen: Non-conductive ink for component legends, logos, and reference designators.

- Bonding Layer (for multi-layer MCPCBs): In more complex, multi-layer MCPCBs, additional prepreg and copper layers can be bonded on top of the initial dielectric and aluminum base. This allows for more complex routing while still benefiting from the thermal advantages.

Material Selection Considerations

When choosing an Aluminum LED PCB, the quality and properties of the dielectric material are paramount. A higher thermal conductivity dielectric, even if slightly more expensive, can significantly improve the overall thermal performance of the LED module, leading to better light output and longer LED life.

APTPCB works with a range of specialized dielectric materials and aluminum alloys to precisely match the thermal, electrical, and mechanical requirements of your specific high-power LED applications.

Design Best Practices for Optimal Thermal Performance

Designing an Aluminum LED PCB goes beyond simply choosing the right materials; it requires a strategic approach to layout that maximizes the inherent thermal advantages of the aluminum core. Here are key design best practices for achieving optimal thermal performance:

1. Maximize Thermal Contact to the Dielectric

- Large Copper Pads Under LEDs: Ensure the thermal pad of the LED package has a generous copper area on the circuit layer. This is the primary heat collection point.

- Minimize Thermal Resistance to Dielectric: The path from the LED pad through the dielectric to the aluminum base is crucial. Avoid any bottlenecks here.

2. Strategic Use of Thermal Vias (If Applicable)

While the aluminum core itself is the main thermal path, thermal vias can still play a role in multi-layer MCPCBs or to facilitate heat transfer to secondary thermal planes.

- Copper-Filled or Paste-Filled Vias: For single-layer MCPCBs, if components other than the LED itself generate heat on the topside, thermal vias connecting to the aluminum base (if the dielectric allows) can be beneficial. However, direct contact with the aluminum base is usually the most efficient path for the LED itself.

- Vias for Secondary Components: Use thermal vias to conduct heat from heat-generating components (e.g., drivers, resistors) on the copper layer to the large thermal mass of the aluminum.

3. Optimize Copper Layout for Heat Spreading

- Wide Traces and Copper Pours: Use the widest possible traces for power and ground connections to the LEDs, not just for current carrying but also for heat spreading. Large, contiguous copper pours around the LED pads further enhance lateral heat distribution before it transfers to the aluminum.

- Minimize Thermal Reliefs Under LEDs: While thermal reliefs are common for soldering on FR-4, avoid them under the thermal pads of high-power LEDs on MCPCBs. You want maximum direct thermal contact, not restricted flow.

4. Consider Aluminum Core Dimensions and Finish

- Adequate Thickness: Choose an aluminum core thickness that provides sufficient thermal mass and mechanical rigidity for your application (e.g., 1.0mm, 1.6mm, 2.0mm). Thicker cores can absorb and spread more heat.

- Surface Finish: The exposed aluminum surface on the back of the PCB can be left bare, anodized, or painted. A flat, clean surface is ideal for mating with an external heat sink using thermal paste or gap pads.

5. Account for Manufacturing Tolerances

- Dielectric Thickness Consistency: Ensure your chosen dielectric thickness is consistent across the board, as variations can impact thermal performance. APTPCB maintains strict control over lamination processes for uniform dielectric layers.

- Copper Etching Accuracy: Precise copper etching ensures that thermal pads are correctly sized and positioned for optimal contact with the LED.

By integrating these design best practices, you can fully harness the thermal advantages of the Aluminum LED PCB, leading to a more efficient, reliable, and longer-lasting LED lighting product. At APTPCB, our DFM (Design for Manufacturability) review process includes a detailed thermal analysis to help you optimize your Aluminum LED PCB designs.

Manufacturing Aluminum LED PCBs: Process and Quality

The manufacturing of Aluminum LED PCBs requires specialized processes and stringent quality control to ensure both electrical integrity and superior thermal performance. It's not merely a standard PCB process applied to a different base; it involves precise material handling and dedicated fabrication steps.

Key Manufacturing Steps

Material Preparation:

- Cutting Aluminum Core: The aluminum sheet is cut to the required panel size.

- Copper Foil Preparation: The specific copper foil thickness for the circuit layer is selected.

- Dielectric Sheet Cutting: The highly thermally conductive dielectric material is cut to size.

Lamination:

- This is a critical step. The copper foil, dielectric layer, and aluminum base are carefully stacked and then bonded together under precise heat and pressure. The quality of this bond is vital for both electrical insulation and thermal transfer.

- APTPCB's Expertise: We use controlled lamination cycles and specialized presses to ensure a void-free, uniform bond between the layers, minimizing thermal resistance across the dielectric.

Circuit Imaging and Etching:

- The copper foil is cleaned, and a photosensitive resist is applied.

- The circuit pattern is then transferred onto the resist using photolithography.

- Unwanted copper is chemically etched away, leaving only the desired circuit traces and pads.

Solder Mask Application:

- A thermally stable solder mask (often white for LED PCBs to enhance reflectivity) is applied and cured, protecting the copper traces and defining the solderable pads.

Surface Finish:

- A surface finish (e.g., HASL, ENIG, OSP) is applied to the exposed copper pads to ensure solderability and protect them from oxidation. For LED PCBs, ENIG (Electroless Nickel Immersion Gold) is often preferred for its excellent flatness and solderability, crucial for fine-pitch LED packages.

Drilling and Routing:

- Holes (for components or mounting) are drilled.

- The individual PCBs are routed from the larger panel. This often requires specialized tooling for aluminum.

Electrical Test (E-Test):

- Every board undergoes an electrical test to check for opens and shorts, ensuring circuit integrity.

Quality Control for Thermal Performance

Beyond standard PCB quality checks, manufacturing Aluminum LED PCBs demands specific attention to thermal characteristics:

- Dielectric Thickness Verification: Ensuring the thin dielectric layer is consistently within tolerance.

- Bonding Integrity: Visual inspection and sometimes destructive testing (cross-sectioning) to verify that the dielectric is perfectly bonded to both copper and aluminum, with no air gaps or delamination.

- Thermal Conductivity Testing (Batch Samples): While not performed on every board, batch testing of the raw dielectric material or sample PCBs can confirm expected thermal performance.

- Copper Thickness Verification: Ensuring the specified copper weight is achieved for optimal current carrying and heat spreading.

APTPCB's Commitment to Excellence

At APTPCB, our manufacturing lines are optimized for high-volume, high-quality production of Aluminum LED PCBs. We combine advanced machinery with a meticulous quality assurance process, including NPI and small-batch PCB manufacturing for prototyping and fine-tuning. This ensures that every Aluminum LED PCB we produce delivers the consistent thermal performance and reliability your high-power LED applications demand, minimizing risks and accelerating your time to market.

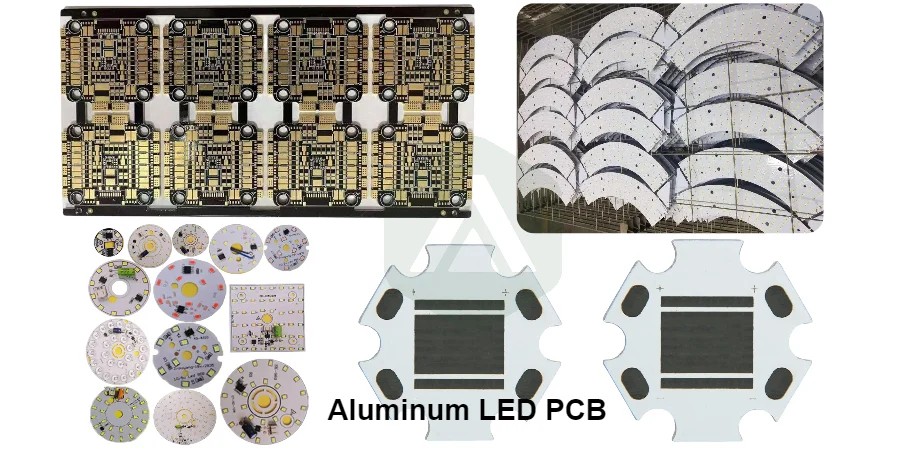

Applications and Future Trends for Aluminum LED PCBs

The superior thermal management capabilities of Aluminum LED PCBs have made them indispensable across a wide spectrum of industries and applications. Their importance will only grow as LED technology continues to advance.

Current Key Applications

High-Power LED Lighting:

- Street Lighting: Essential for long-lasting, bright, and reliable municipal lighting.

- Automotive Lighting: Headlights, taillights, daytime running lights where brightness, durability, and compact design are critical.

- Industrial and Commercial Lighting: High-bay lighting, panel lights, floodlights requiring robust performance in demanding environments.

- Architectural Lighting: High-intensity accent and facade lighting.

- Grow Lights: High-power horticultural lighting systems that generate significant heat.

Display Technologies:

- LED Backlights: For LCD TVs, monitors, and specialized displays where uniform, bright, and long-lasting backlighting is needed.

- Large-Format LED Displays: Outdoor billboards and indoor video walls where individual LED modules must dissipate heat efficiently.

Power Electronics:

- Beyond just LEDs, any application with high heat-generating components can benefit from MCPCBs. This includes power regulators, motor controllers, and voltage converters where the aluminum base can serve as an integrated heat spreader.

Future Trends and Innovations

The demand for Aluminum LED PCBs is constantly pushing innovation in materials and manufacturing techniques:

- Thinner, More Thermally Conductive Dielectrics: Ongoing research aims to develop even thinner dielectric layers with higher thermal conductivity to reduce thermal resistance further, allowing for smaller, more powerful LED modules.

- Hybrid MCPCBs: Combining aluminum with other materials or integrating multiple copper layers on top of the dielectric for more complex signal routing, while still leveraging the aluminum for primary heat dissipation.

- Advanced Surface Finishes: Development of new surface treatments for the aluminum core that enhance emissivity for passive cooling, or improve adhesion for direct thermal interfaces.

- Integration with Advanced Cooling: Seamless integration with heat pipes, vapor chambers, or even liquid cooling channels for ultra-high-power LED arrays.

- Miniaturization: As LEDs become smaller and more powerful (e.g., Micro-LEDs), the need for highly efficient, compact Aluminum LED PCBs will intensify to manage localized heat hotspots.

- Smart Lighting Integration: As LED PCBs become part of intelligent lighting systems, they will increasingly need to accommodate more complex control circuitry alongside high-power LEDs, potentially leading to more sophisticated multi-layer Aluminum PCB designs.

Partnering for the Future of LED Technology

At APTPCB, we are not just manufacturing Aluminum LED PCBs; we are actively contributing to the evolution of LED technology. Our continuous investment in R&D, advanced materials, and precise manufacturing processes positions us as a leading partner for innovators in the lighting and power electronics industries.

Whether you are designing the next generation of automotive headlights, developing compact industrial lighting, or exploring new applications for high-power LEDs, APTPCB has the expertise and manufacturing capability to turn your concepts into reliable, high-performing products. Contact us today to discuss your Aluminum LED PCB requirements and let us help you illuminate the future.