In modern LED lighting and high-power electronics, thermal management is one of the most critical design challenges. When a standard FR-4 PCB cannot remove heat fast enough, junction temperatures rise, light output drops, and product lifetime is shortened.

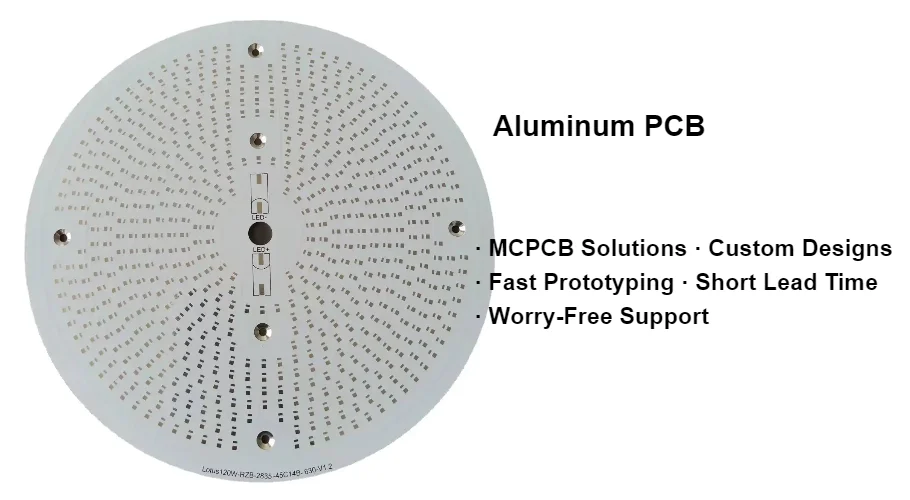

This is where the aluminum PCB—also known as metal core PCB (MCPCB) or LED aluminum PCB—has become a core solution. By combining a thermally conductive aluminum base with a special dielectric layer and copper circuit, aluminum PCBs are designed specifically to handle high thermal loads.

As a PCB manufacturing and PCB assembly factory, we provide complete aluminum PCB and LED PCBA services. This article explains what aluminum PCBs are, how they work, where they are used, and what to consider when selecting an aluminum PCB manufacturer.

Table of Contents

- 1. What Is an Aluminum PCB and Why Is It Ideal for LED Thermal Management?

- 2. How an Aluminum PCB Works: Core Stack-Up and Layer Structure

- 3. Key Design Guidelines for Aluminum PCB (LED Aluminum Board)

- 4. Typical Application Fields of Aluminum PCBs

- 5. How to Choose the Right Aluminum PCB Manufacturer (and PCBA Partner)

- Conclusion: Aluminum PCBs as a Core Part of Your Thermal Strategy

1. What Is an Aluminum PCB and Why Is It Ideal for LED Thermal Management?

High-brightness LEDs are efficient, but a significant portion of the input power is still converted into heat. If that heat is not carried away quickly, it leads to:

- Faster light decay (lumen depreciation) – brightness drops much earlier than expected.

- Shorter LED lifetime – chip and package materials age faster at high temperature.

- Color shift – color temperature and CRI stability are affected.

- Lower reliability – in extreme cases, LED or driver failure.

Standard FR-4 glass-epoxy PCBs have low thermal conductivity, so they struggle to dissipate the heat generated by high-power LEDs and power devices.

An aluminum PCB is a PCB specifically designed for heat dissipation. It uses a thermally conductive aluminum alloy base instead of a standard FR-4 core. Heat flows from the LED pad through the copper layer, then through a thermally conductive dielectric into the aluminum base, and finally into the ambient environment.

Key Advantages of Aluminum PCBs for LED & Power

- High-Efficiency Heat Dissipation

Significantly lowers LED junction temperature, extends lifetime, and improves reliability. - Stable Performance and Light Output

Better thermal control keeps luminous flux, color, and driver performance stable over time. - Simplified Mechanical Structure

The aluminum base can partially or fully replace bulky external heatsinks, helping reduce size and weight. - Improved Mechanical Strength

The metal core increases rigidity, especially useful for large LED modules. - Additional EMI/EMC Benefits

The aluminum base can contribute to grounding and shielding strategies in some designs.

2. How an Aluminum PCB Works: Core Stack-Up and Layer Structure

The superior thermal behavior of an aluminum PCB comes from its special stack-up. A typical aluminum PCB for LED lighting includes four functional layers:

Copper Circuit Layer

- Function: Carries the electrical traces and pads that connect LEDs and other components.

- Features: Copper thickness usually ranges from 1 oz to 3 oz (or higher) to support high current and help spread heat across the board.

Thermal Insulating Dielectric Layer

- Function: Electrically insulates the copper from the aluminum base while conducting heat as efficiently as possible.

- Features:

- Made from thermally conductive polymer or ceramic-filled materials.

- Thermal conductivity typically from 1.0 W/m·K up to 8.0 W/m·K or more, depending on performance and cost.

- This is the “heart” of the aluminum PCB—its quality strongly impacts thermal performance and breakdown voltage.

Aluminum Base Layer

- Function: Acts as the mechanical support and main heat spreader, rapidly distributing heat from hot spots and releasing it via conduction, convection, and radiation.

- Features:

- Common aluminum alloys include 1050/1060, 5052, 6061, etc.

- Typical thickness from 0.8 mm to 3.0 mm, chosen based on thermal, mechanical, and cost requirements.

Solder Mask and Protective Layer

- Function: Protects copper from oxidation and contamination, and prevents solder bridges during reflow.

- Features:

- For LED PCBs, white solder mask is often preferred because of its high reflectivity, helping improve light output and uniformity.

3. Key Design Guidelines for Aluminum PCB (LED Aluminum Board)

A good aluminum PCB design is more than “changing FR-4 to aluminum”. To really unlock its thermal benefits, layout and stack-up must be planned carefully.

Practical Design Tips for Aluminum LED PCBs

Select the Right Thermal Dielectric

- Match thermal conductivity to LED power and density.

- High-power LED arrays and compact drivers usually require higher-k dielectric materials.

Optimize Copper Thickness and Thermal Pads

- Use thicker copper and enlarged thermal pads under LEDs and power devices to spread heat laterally.

- Connect high-power pads to large copper pours to reduce local hot spots.

Use Thermal Vias Where Applicable

- In hybrid designs (FR-4 + aluminum base or heatsink), use dense thermal via arrays under hot components.

- Consider via-filling and thermal interface materials to improve vertical heat conduction.

Component Placement and Heat Path Planning

- Place high-power LEDs, MOSFETs, power ICs, and rectifiers close to areas where heat can flow efficiently into the aluminum base or heatsink.

- Keep temperature-sensitive components away from hot zones or add thermal isolation.

Aluminum Thickness and Mechanical Considerations

- Choose the aluminum thickness based on total power, mechanical strength, and weight.

- Larger modules or fixtures often benefit from thicker plates for stiffness and spreading.

Solder Mask Color and Optical Design

- For LED boards, choose white solder mask to increase reflectivity and system efficacy.

- Plan pad and mask openings to support optical uniformity and avoid glare or unwanted dark zones.

Electrical Safety & Clearance to Metal

- Ensure sufficient creepage and clearance distances between high-voltage circuits and the aluminum base.

- Verify dielectric breakdown performance to comply with relevant safety standards (e.g., for AC mains, automotive, medical).

4. Typical Application Fields of Aluminum PCBs

Thanks to their combination of thermal, mechanical, and cost advantages, aluminum PCBs are widely used in many high-power and thermally demanding products.

Common Aluminum PCB Applications

High-Power LED Lighting

- Street lights, tunnel lights, floodlights

- High-bay and low-bay industrial lamps

- Automotive LED headlights, DRLs, and signal lights

- Stage lighting and plant grow lights

- Architectural and outdoor LED modules

Power Supply and Power Conversion

- High-wattage AC/DC and DC/DC power supplies

- LED drivers and constant-current modules

- Inverters, rectifiers, PFC circuits

- Solid-state relays and power controllers

Automotive Electronics

- LED lighting modules

- On-board chargers, DC/DC converters

- Power amplifier boards and engine control power stages

Medical and Industrial Equipment

- Medical lighting and examination lamps

- Ultrasound, laser, and imaging equipment modules

- Motor drivers, inverters, industrial control power modules

High-Power Consumer Electronics

- Audio power amplifiers

- TV backlight strips and LED bars

- Gaming and display backlight modules

5. How to Choose the Right Aluminum PCB Manufacturer (and In-House PCB Assembly (PCBA) Partner)

Selecting a capable aluminum PCB manufacturer is essential to ensure real-world thermal performance and long-term reliability. Aluminum PCBs require different materials and processes than FR-4, so experience and process control are critical.

Points to Evaluate When Choosing an Aluminum PCB Factory

Proven Aluminum PCB / MCPCB Experience

- Check their track record with high-power LED and power electronics projects.

- Ask for sample stack-ups, typical panel sizes, and reference applications.

Dedicated Equipment and Process Capability

- Precision etching, drilling, routing, and surface finishing suitable for metal core boards.

- Stable control of dielectric thickness, thermal conductivity, and lamination parameters.

Quality Control and Testing

- Incoming material inspection (aluminum flatness, dielectric properties).

- AOI, electrical testing, and where needed, thermal performance verification.

- Clear process documentation and full production traceability.

Material and Stack-Up Flexibility

- Multiple options for thermal conductivity, copper thickness, and aluminum thickness.

- Support for white solder mask, ENIG/OSP/HASL finishes, and special requirements.

Engineering Support: DFM and Thermal Optimization

- Ability to review your Gerber files and propose improvements for heat spreading, creepage, and manufacturability.

- Help with choosing appropriate stack-ups, pad shapes, and panelization.

In-House PCB Assembly (PCBA) Capability

- SMT assembly for LED modules and power boards on aluminum substrates.

- Optimized reflow profiles and handling methods for metal core PCBs.

Conclusion: Aluminum PCBs as a Core Part of Your Thermal Strategy

An aluminum PCB is not just “another circuit board”—it is a key thermal management component for high-power LEDs and demanding power electronics. Understanding its structure, design rules, and manufacturing constraints helps you design products that are brighter, cooler, more reliable, and longer-lasting.

As a PCB manufacturing and PCB assembly factory, we provide:

- Custom aluminum PCB manufacturing (single-layer and multi-layer MCPCB)

- LED module and power PCBA services

- DFM and thermal design support

- Stable mass production with strict quality control

By working with a professional aluminum PCB manufacturer and PCBA partner, you can fully unlock the performance potential of your LED and power designs and stand out in a highly competitive market.