Contents

- Highlights

- Annular Ring Rules and Drill Tolerance for PCB: Definition and Scope

- Annular Ring Rules and Drill Tolerance for PCB Rules and Specifications

- Annular Ring Rules and Drill Tolerance for PCB Implementation Steps

- Annular Ring Rules and Drill Tolerance for PCB Troubleshooting

- Supplier Qualification Checklist: How to Vet Your Fab

- Glossary

- 6 Essential Rules for Annular Ring Rules and Drill Tolerance for PCB (Cheat Sheet)

- FAQ

- Request a Quote / DFM Review for Annular Ring Rules and Drill Tolerance for PCB

- Conclusion

In the precision world of printed circuit board manufacturing, few parameters cause as many scrapped boards or reliability failures as the annular ring. Simply put, the annular ring is the area of copper pad that remains around a drilled hole after the drilling process is complete. It is the critical bridge between the mechanical hole and the electrical trace. If the drill wanders slightly off-center—a phenomenon governed by drill tolerance—and the annular ring is insufficient, the drill bit may sever the connection to the trace or disconnect the via from the internal planes.

At APTPCB, we review hundreds of Gerber files weekly where the annular ring is mathematically present in the CAD design but statistically likely to fail on the production floor due to unrealistic tolerance expectations. Understanding the interplay between annular ring rules and drill tolerance for pcb is not just about passing a Design Rule Check (DRC); it is about ensuring the physical survivability of the connection during thermal cycling and mechanical stress.

Quick Answer

For a standard rigid PCB (IPC Class 2), the "Golden Rule" for ensuring a robust annular ring is to size your pad at least 10 to 14 mils (0.25mm to 0.35mm) larger than the finished hole size.

- The Rule: Pad Diameter = Finished Hole Size + 0.10mm (Plating Allowance) + 2 × (Minimum Annular Ring + Drill Tolerance).

- The Pitfall: Designing based on "Finished Hole Size" without accounting for the fact that we must drill larger (by ~0.1mm to 0.15mm) to allow room for plating. This reduces your effective annular ring.

- The Verification: Always run a DFM analysis that checks against the drill tool size, not just the finished hole size.

Highlights

- Drill Wander is Inevitable: Even high-end CNC machines have a runout. Standard manufacturing tolerance is typically ±3 mil (0.075mm). Your annular ring must absorb this deviation.

- IPC Class Differences: IPC-6012 Class 2 allows for 90° breakout (drill exiting the side of the pad) as long as the connection is maintained. Class 3 (Aerospace/Medical) requires a minimum of 1 mil (0.025mm) of copper remaining inside the hole wall.

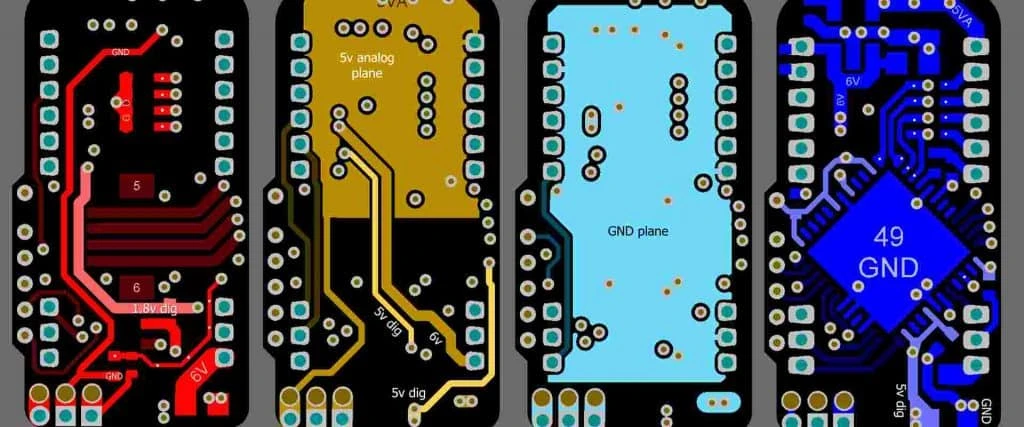

- Layer Movement: In multilayer PCB fabrication, inner layers can shift slightly during the high-pressure lamination process, making inner-layer annular rings more susceptible to misalignment than outer layers.

- Teardrops are Essential: Adding teardrops to your pad-trace junctions provides a mechanical backup, ensuring connectivity even if the drill breaks out of the annular ring slightly.

Annular Ring Rules and Drill Tolerance for PCB: Definition and Scope

To master annular ring rules and drill tolerance for pcb, one must first understand the geometry and the manufacturing reality that alters that geometry.

The Geometry of the Annular Ring

The annular ring is calculated as: $$ \text{Annular Ring} = \frac{(\text{Pad Diameter} - \text{Drill Diameter})}{2} $$

However, the "Drill Diameter" in this equation is the Tool Size, not the Finished Hole Size.

- Finished Hole Size: The dimension you specify in your CAD software (e.g., 0.3mm via).

- Tool Size: The actual drill bit used by the manufacturer. For Plated Through Holes (PTH), we typically use a drill bit 0.1mm to 0.15mm larger than the finished size to account for the copper plating thickness inside the barrel.

If you design a 0.5mm pad for a 0.3mm via, you might think you have a 0.1mm (4 mil) annular ring. $$ (0.5 - 0.3) / 2 = 0.1mm $$ But in reality, we drill with a 0.4mm bit. $$ (0.5 - 0.4) / 2 = 0.05mm $$ You actually only have 2 mils of copper ring. If the drill wanders by 3 mils (standard tolerance), the hole will break out of the pad.

The Scope of Drill Tolerance

Drill tolerance is the sum of several mechanical inaccuracies:

- Spindle Runout: The wobble of the drill bit as it spins at 100k+ RPM.

- Bit Deflection: The bending of the drill bit as it hits the fiberglass weave or copper foil.

- Table Movement: The positioning accuracy of the CNC machine (typically ±1 mil).

- Material Movement: The expansion and contraction of the PCB panel during processing.

When we discuss annular ring rules and drill tolerance for pcb, we are essentially calculating a safety margin. The annular ring must be large enough to absorb all these errors and still leave a connection.

Tech / Decision Lever → Practical Impact

| Decision Lever / Spec | Practical Impact (Yield/Cost/Reliability) |

|---|---|

| Pad Size vs. Hole Size Ratio | Increasing pad size improves yield (easier to hit) but reduces routing space for traces, potentially forcing more layers (higher cost). |

| Mechanical vs. Laser Drill | Laser drills (for [HDI PCB](/pcb/hdi-pcb)) are far more accurate (±1 mil tolerance) than mechanical drills, allowing smaller annular rings but increasing fabrication cost. |

| IPC Class 2 vs. Class 3 | Class 2 allows "breakout" (tangency), permitting tighter designs. Class 3 demands 1mil internal ring, requiring larger pads and stricter process controls. |

| Teardrops Enabled | Virtually zero cost impact but significantly increases reliability by preventing trace-to-pad severance during drill wander. |

Annular Ring Rules and Drill Tolerance for PCB Rules and Specifications

To ensure manufacturability, designers must adhere to specific rules based on the density of the board and the capabilities of the manufacturer. Below are the standard specifications used at APTPCB for standard and advanced rigid boards.

| Rule / Parameter | Standard Value (Class 2) | Advanced Value (HDI/Class 3) | Why it matters | How to verify |

|---|---|---|---|---|

| Min Annular Ring (Outer Layers) | 5 mil (0.127mm) | 3.5 mil (0.089mm) | Outer layers are easier to align, but plating thickness adds variability. | CAD DRC: Check Pad vs. Hole size. |

| Min Annular Ring (Inner Layers) | 5 mil (0.127mm) | 4 mil (0.10mm) | Inner layers shift during lamination; requires larger buffer than outer layers. | CAD DRC: Check Inner Pad vs. Hole. |

| Drill Tolerance (Positional) | ±3 mil (0.075mm) | ±2 mil (0.05mm) | Defines the "wander" zone. Tighter tolerance requires slower drilling/better equipment. | Check Fab Notes / Supplier Capabilities. |

| Pad Diameter Calculation | Hole + 10-12 mil | Hole + 8-10 mil | Ensures the ring survives the drill tolerance. | Measure in Gerber Viewer. |

| Teardrops | Recommended | Mandatory | Prevents open circuits if breakout occurs. | Visual inspection of trace entry. |

| Clearance (Pad to Copper) | 8 mil (0.2mm) | 5 mil (0.127mm) | Prevents shorts if the drill wanders and pushes copper, or if registration is off. | CAD DRC: Clearance Rules. |

The "Tangency" Concept

In IPC Class 2, tangency is acceptable. This means the edge of the drilled hole can touch the edge of the pad. In fact, 90 degrees of breakout is allowed provided the conductor junction is not reduced.

- Design Implication: You can push the limits of density.

- Risk: If the breakout occurs exactly where the trace enters the pad, you lose connection. This is why teardrops are vital.

In IPC Class 3 (High Reliability), tangency is a defect. You must have a measurable ring (usually 1 mil or 2 mil) around the entire hole.

- Design Implication: You must use larger pads, which reduces routing density.

Annular Ring Rules and Drill Tolerance for PCB Implementation Steps

Implementing robust annular ring rules and drill tolerance for pcb begins in the CAD setup phase, long before the design reaches the factory.

Implementation Process

Step-by-step execution guide for robust pad design

Do not guess. Use the formula: Pad = Finished Hole + 0.1mm (Plating) + 2 × (Min Ring + Tolerance). For a 0.3mm via, this usually results in a 0.55mm or 0.6mm pad.

Input these rules into your PCB design software (Altium, KiCad, Eagle). Set separate rules for "Via" vs. "Component Pad" if possible, as component pads often need larger rings for soldering.

Enable automatic teardrop generation. This adds a fillet of copper at the junction of the trace and the pad. It is the cheapest insurance policy against drill breakout disconnecting a signal.

Before sending files, run a DFM check (or use our [free DFM tools](/tools/gerber-viewer)). Look specifically for "Annular Ring Violations" where the ring dips below 4-5 mils.

Annular Ring Rules and Drill Tolerance for PCB Troubleshooting

Even with good design, issues can arise. Here are common failure modes related to annular rings and how we solve them at the factory level.

1. Breakout (Drill Exits the Pad)

- Symptom: Visual inspection shows the hole edge cutting through the pad edge. In severe cases, the connection to the trace is severed (Open Circuit).

- Root Cause: Usually a combination of tight design (insufficient annular ring) and normal manufacturing tolerance stack-up (drill wander + layer shift).

- Fix:

- Design: Increase pad size or use teardrops.

- Fab: Use X-ray drilling optimization (Smart Drilling) to align the drill to the copper pads rather than the theoretical grid.

2. Registration Errors (Layer-to-Layer Misalignment)

- Symptom: The drill is perfectly centered on the top layer but breaks out on internal layer 4.

- Root Cause: Material scaling. During lamination, the core material expands and flows. If the manufacturer doesn't apply the correct "scaling factors" to the artwork, the inner layers won't match the drill map.

- Fix: We use historical data to predict material movement and scale the artwork (e.g., scale by 100.05%) to match the cured state of the board.

3. Insufficient Plating in Hole

- Symptom: The hole is drilled correctly, but the electrical resistance is high or intermittent.

- Root Cause: While not strictly an annular ring issue, if the ring is too small, the "knee" (where the plating wraps from the barrel to the surface) becomes a stress point.

- Fix: Ensure PCB drilling quality is high (no rough walls) to allow smooth plating, and ensure the annular ring is large enough to anchor the barrel plating.

Supplier Qualification Checklist: How to Vet Your Fab

When selecting a manufacturer for boards with tight annular ring rules and drill tolerance for pcb, ask these questions to ensure they can meet your specs.

- What is your standard drill positional tolerance? (Standard is ±3 mil; Advanced is ±1-2 mil).

- Do you use X-ray optimization for drilling? (Essential for multilayer boards to align drills to inner layers).

- What is your minimum annular ring for Class 2 vs. Class 3? (Verify they understand the difference).

- Do you apply scaling factors to artwork to compensate for lamination movement? (If they say "no," avoid them for multilayer boards).

- Can you handle teardrop generation if I forget to add them? (Good CAM engineers will offer to add them for you).

- What is your aspect ratio limit for plating? (High aspect ratios require larger holes, affecting annular ring calculations).

- Do you perform cross-section analysis to verify internal annular ring alignment? (Critical for validating Class 3 compliance).

Glossary

Annular Ring: The ring of copper around a plated through-hole. It is the pad area minus the hole area.

Breakout: A condition where the drilled hole is not fully enclosed by the land (pad), causing the hole to cut through the edge of the pad.

Drill Wander: The deviation of the drill bit from its intended target location due to spindle runout, bit deflection, or vibration.

Teardrop: A reinforcement shape added to the junction of a pad and a trace to prevent connection failure in the event of drill breakout.

IPC-6012: The qualification and performance specification for rigid printed boards, defining Class 1, 2, and 3 reliability levels.

Aspect Ratio: The ratio of the PCB thickness to the diameter of the drilled hole. Higher aspect ratios (e.g., 10:1) are harder to plate and drill accurately.

6 Essential Rules for Annular Ring Rules and Drill Tolerance for PCB (Cheat Sheet)

| Rule / Guideline | Why It Matters (Physics/Cost) | Target Value / Action |

|---|---|---|

| Standard Via Pad Size | Ensures ring survives standard drill wander without breakout. | Hole + 10-12 mil (0.25-0.3mm) |

| Component Lead Pad | Needs extra area for solder fillet and mechanical strength. | Hole + 14-20 mil (0.35-0.5mm) |

| Drill Tolerance Assumption | Never assume perfect drilling. Always budget for error. | ±3 mil (Standard Fab) |

| Teardrops | Prevents open circuits during breakout. Zero cost impact. | Always ON |

| IPC Class 3 Requirement | High reliability demands no breakout. | 1 mil internal ring (Min) |

| Laser Microvia (HDI) | Laser is more precise than mechanical drills. | Hole + 5-6 mil |

FAQ

Q: What is the absolute minimum annular ring I can use for a standard prototype?

A: For standard "quick turn" prototypes without extra cost, we recommend a minimum annular ring of 4 to 5 mils (0.1mm to 0.127mm). Going below 4 mils often pushes the board into "advanced" fabrication categories, which may increase cost and lead time due to the need for tighter process controls and inspection.

Q: Does the annular ring rule apply to Non-Plated Through Holes (NPTH)?

A: Yes, but differently. Since NPTHs do not have plating in the barrel, the annular ring is purely for mechanical support or soldering on the surface. However, because NPTHs are often drilled in a secondary operation (or with different bits), the tolerance requirements are similar. We generally recommend a larger clearance (anti-pad) for NPTHs to prevent accidental shorts to internal planes.

Q: Why is the "Finished Hole Size" different from the "Drill Tool Size"?

A: To create a Plated Through Hole (PTH), we must drill a hole slightly larger than your desired final diameter. We then plate copper into that hole. The plating thickness is typically 0.8 to 1.0 mil (20-25 microns). Therefore, the drill tool is usually 4 to 5 mils (0.1mm to 0.15mm) larger than the finished hole. Your annular ring calculation must account for this larger drill bit removing more of your pad.

Q: Can I use oblong or square pads to increase annular ring?

A: Yes! This is a common technique for high-density connectors (like D-Subs or headers). Using an oblong (oval) pad allows you to maintain a large annular ring in the long dimension (for mechanical strength) while keeping the pad narrow in the short dimension to maintain clearance between pins.

Q: How does layer count affect drill tolerance?

A: As layer count increases, the difficulty of aligning the drill to every single inner layer increases. Material scaling (expansion/contraction) becomes more complex to predict across 10, 12, or 20 layers. For high-layer-count boards, we often require slightly larger annular rings on inner layers to accommodate this "registration tolerance."

Q: What happens if I ignore the annular ring rules?

A: Best case: The manufacturer puts your job on hold and asks you to resize the pads (Engineering Query). Worst case: The board is manufactured, drill breakout occurs, and you experience intermittent open circuits that only appear when the board heats up or vibrates, leading to difficult-to-diagnose field failures.

Request a Quote / DFM Review for Annular Ring Rules and Drill Tolerance for PCB

Ready to move your design from CAD to reality? Ensure your annular rings are robust and your tolerances are manufacturable. Send your files to APTPCB for a comprehensive DFM review.

- Gerber Files (RS-274X): Include all copper layers, drill files, and solder mask.

- Drill File: Clearly specify Finished Hole Sizes.

- Stackup Diagram: Indicate material types and layer order.

- IPC Class Requirement: Specify Class 2 or Class 3.

Conclusion

Mastering annular ring rules and drill tolerance for pcb is a balancing act between density and reliability. While modern fabrication equipment is incredibly precise, the physics of material movement and mechanical drilling means that tolerance is a reality we must design for. By following the "Hole + 10mil" rule, utilizing teardrops, and understanding the difference between tool size and finished size, you can virtually eliminate breakout defects.

At APTPCB, we combine advanced X-ray drilling optimization with rigorous quality control to ensure that even the tightest annular rings meet specification. Whether you are building a simple prototype or a complex Class 3 aerospace board, our engineering team is here to guide your stackup and layout for maximum yield.

Signed, The Engineering Team at APTPCB