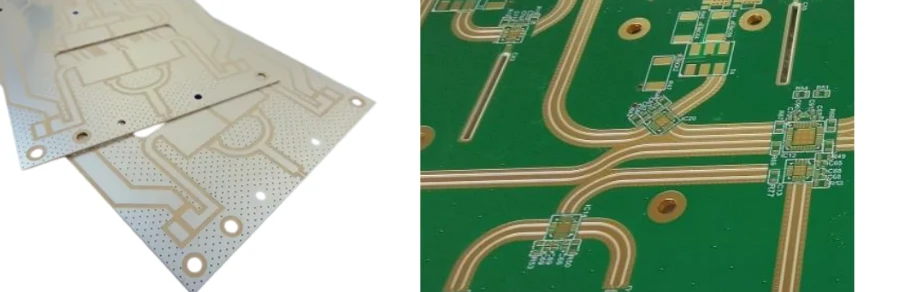

Antenna tuning and trimming is the critical process of adjusting an RF antenna's electrical or physical properties to ensure it resonates at the correct frequency and matches the system impedance (typically 50 Ohms). Without precise tuning, wireless devices suffer from reduced range, high power consumption, and signal dropouts. APTPCB (APTPCB PCB Factory) specializes in manufacturing high-frequency PCBs that support rigorous tuning requirements for IoT, automotive, and aerospace applications.

Antenna tuning and trimming quick answer (30 seconds)

- Goal: Achieve a Voltage Standing Wave Ratio (VSWR) of less than 2:1 or Return Loss better than -10dB at the operating frequency.

- Tuning vs. Trimming: Tuning usually involves adjusting capacitor and inductor values in a matching network (Pi or T network). Trimming involves physically cutting the antenna trace to shorten its electrical length, shifting the resonant frequency higher.

- Environment Matters: Always perform antenna tuning and trimming with the PCB inside its final enclosure (housing), as plastic and batteries shift the resonant frequency.

- Ground Plane: Ensure the ground plane clearance matches the datasheet exactly; deviations require significant re-tuning.

- Validation: A Vector Network Analyzer (VNA) is mandatory for verifying the Smith Chart impedance curve.

- Material Stability: Use stable substrates like Rogers or Teflon to prevent frequency drift due to temperature or humidity changes.

When antenna tuning and trimming applies (and when it doesn’t)

When it applies:

- Custom Trace Antennas: Designs using PCB traces (inverted-F, meander line) require physical trimming during the prototyping phase to account for substrate dielectric variations.

- Enclosure Integration: When a PCB is placed into a plastic or metal housing, the dielectric loading changes, requiring component value adjustments (tuning).

- Material Changes: Switching from FR4 to a high-frequency laminate alters the effective dielectric constant ($D_k$), necessitating re-tuning.

- Multi-band Applications: Devices operating on multiple bands (e.g., cellular + Wi-Fi) often need precise matching networks to isolate frequencies.

- High-Volume Production: Statistical tuning is applied to ensure yield when component tolerances vary.

When it doesn’t apply:

- Pre-certified Modules: RF modules with integrated ceramic chip antennas often forbid external tuning to maintain FCC/CE certification.

- Low-Frequency Non-Resonant Systems: Some NFC or RFID tags use magnetic induction where geometry is fixed, and only the reader side is tuned.

- Digital-Only Boards: PCBs without wireless transmission capabilities do not require antenna work.

- Wideband Antennas (sometimes): Ultra-wideband (UWB) antennas are designed to be less sensitive to minor detuning, though performance checks are still recommended.

Antenna tuning and trimming rules and specifications (key parameters and limits)

Adhering to specific rules ensures that the antenna radiates efficiently. The following table outlines critical parameters for successful antenna tuning and trimming.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Target Impedance | $50\Omega \pm 2\Omega$ (typical) | Maximizes power transfer; minimizes reflection. | VNA (Smith Chart center). | High signal reflection, poor range. |

| VSWR Limit | $< 2.0:1$ (ideally $< 1.5:1$) | Indicates efficiency of the match. | VNA measurement. | Power wasted as heat; transmitter damage. |

| Return Loss | $< -10\text{dB}$ | Correlates to 90% power delivered to antenna. | S11 parameter on VNA. | Weak signal reception. |

| Matching Network | Pi-network (Series/Shunt) | Allows flexibility to tune impedance in any direction. | Schematic review. | Inability to correct impedance shifts. |

| Trace Clearance | $> 2\times$ trace width (min) | Prevents parasitic coupling to ground. | Gerber viewer / DRC. | Antenna detuning; efficiency loss. |

| Component Tolerance | $\pm 0.1\text{pF}$ or $\pm 1%$ | High precision required for high frequencies ($> 2.4\text{GHz}$). | BOM check. | Inconsistent tuning across batches. |

| Via Stitching | $\lambda / 20$ spacing | Prevents ground loops and edge radiation. | Visual inspection. | Unstable radiation pattern. |

| Solder Mask | Keep out over antenna | Solder mask adds dielectric loss and shifts frequency. | Gerber viewer. | Frequency shifts down; higher loss. |

| Copper Thickness | 1 oz (standard) | Affects resistance and bandwidth slightly. | Cross-section analysis. | Minor efficiency variance. |

| Substrate $D_k$ | Tight tolerance ($\pm 0.05$) | Determines electrical length of the antenna. | Material datasheet. | Resonant frequency misses target. |

Antenna tuning and trimming implementation steps (process checkpoints)

Follow these steps to implement antenna tuning and trimming during the NPI (New Product Introduction) phase.

Simulation and Initial Layout:

- Action: Design the antenna trace slightly longer than calculated.

- Parameter: Target frequency (e.g., 2.45 GHz).

- Check: Ensure a Pi-matching network footprint (0402 or 0201 size) is placed immediately at the antenna feed point.

Fabrication of Bare Board:

- Action: Manufacture the PCB with controlled impedance stackup.

- Parameter: Dielectric constant ($D_k$) control.

- Check: Verify stackup matches the simulation using an impedance calculator.

Baseline Measurement (Passive):

- Action: Solder a semi-rigid coax cable (pigtail) to the antenna feed point. Disconnect the radio chip.

- Parameter: S11 (Return Loss).

- Check: Measure the natural resonant frequency of the untuned antenna in free space.

Physical Trimming (If applicable):

- Action: If the resonant frequency is too low, carefully cut (trim) the distal end of the antenna trace.

- Parameter: Length reduction (0.5mm increments).

- Check: Frequency should shift upward. Stop when resonance is slightly above the target (housing will shift it down).

Housing Integration:

- Action: Place the PCB into the final plastic enclosure with batteries and screws.

- Parameter: Frequency shift (usually downward).

- Check: Re-measure S11. The plastic usually lowers the frequency and alters impedance.

Component Tuning (Matching Network):

- Action: Use the Smith Chart on the VNA to calculate required series/shunt inductors and capacitors.

- Parameter: Impedance move to $50\Omega$ center.

- Check: Solder calculated components and verify VSWR $< 2:1$ across the bandwidth.

Active Testing:

- Action: Connect the radio and run throughput or RSSI tests.

- Parameter: Packet Error Rate (PER).

- Check: Ensure real-world performance matches VNA data.

Documentation for Mass Production:

- Action: Lock the BOM values and antenna length.

- Parameter: Fixed component values.

- Check: Update fabrication drawings to ensure no copper pour changes in future revisions.

Antenna tuning and trimming troubleshooting (failure modes and fixes)

When performance fails, use this logic flow to diagnose issues related to antenna tuning and trimming.

Symptom: Resonant frequency is too low.

- Cause: Antenna trace is too long, or enclosure plastic $D_k$ is higher than expected.

- Check: Measure S11 without the enclosure.

- Fix: Trim the antenna length physically or use a series capacitor to shorten the electrical length.

- Prevention: Design the initial prototype antenna 10% shorter and use a 0-ohm resistor to extend if needed, or design it longer and trim back.

Symptom: High VSWR despite tuning.

- Cause: Metal objects (screws, battery, shield cans) are too close to the radiator.

- Check: Inspect the "Keep-out Zone" on all layers.

- Fix: Move the antenna or the metal object; increase ground clearance.

- Prevention: Define strict 3D keep-out zones in mechanical CAD.

Symptom: Tuning drifts when touched.

- Cause: "Hand effect" or weak ground plane reference.

- Check: Touch the board edge while watching the VNA.

- Fix: Improve grounding; add a larger ground plane or counterpoise.

- Prevention: Simulate human body interaction during design.

Symptom: Narrow Bandwidth.

- Cause: High-Q factor due to thin traces or thick substrate.

- Check: Verify trace width and substrate thickness.

- Fix: Widen the antenna trace or use a lower Q matching network.

- Prevention: Choose antenna PCB substrates optimized for bandwidth.

Symptom: Performance varies between batches.

- Cause: FR4 dielectric constant variation or etching tolerance issues.

- Check: Compare $D_k$ specs of the laminate batch.

- Fix: Switch to controlled dielectric materials or tighten etching tolerances.

- Prevention: Specify "Controlled Impedance" on fab notes.

Symptom: Signal loss in matching network.

- Cause: Low-Q inductors/capacitors used.

- Check: Verify component ESR/Q-factor at operating frequency.

- Fix: Use high-Q RF grade components (e.g., wire-wound inductors).

- Prevention: Specify RF-grade series in BOM.

How to choose: Tuning vs. Trimming vs. Ceramic Antennas

Deciding between physical trimming, component tuning, or using a ceramic chip depends on volume and precision.

1. Component Tuning (Lumped Elements)

- Best for: High-volume production, adjusting for enclosure effects without changing the PCB layout.

- Pros: Non-destructive, flexible, easy to automate pick-and-place.

- Cons: Adds BOM cost, introduces insertion loss.

2. Physical Trimming (Laser/Mechanical)

- Best for: Prototyping, ultra-high frequency (mmWave) where components add too much parasitic inductance.

- Pros: No added components, highest efficiency.

- Cons: Destructive, difficult to reverse, expensive for mass production (laser trimming).

3. Ceramic Chip Antennas

- Best for: Space-constrained designs, standard protocols (Bluetooth/Wi-Fi).

- Pros: Pre-tuned (mostly), small footprint.

- Cons: Still requires a matching network (tuning) to compensate for the ground plane size; less efficient than a full-size trace antenna.

Antenna tuning and trimming FAQ (cost, lead time, Design for Manufacturability (DFM))

Q: How does antenna tuning and trimming affect PCB cost? A: Physical trimming is labor-intensive and usually restricted to prototyping. For mass production, cost is driven by the need for high-precision components (High-Q) and potentially more expensive RF laminates. APTPCB optimizes cost by suggesting standard stackups that minimize variation.

Q: What is the lead time for boards requiring impedance control for antennas? A: Standard lead time is 5-7 days. If special materials (Rogers, Taconic) are required for stable tuning, lead time may extend to 10-12 days depending on stock.

Q: What files are needed for DFM regarding antenna tuning? A: Submit Gerber files, a stackup drawing specifying the target dielectric constant, and a drill file. Clearly mark the antenna keep-out zones on the silkscreen or assembly drawing.

Q: Can I tune an antenna without a VNA? A: No. While you can measure RSSI (signal strength), you cannot determine if the issue is impedance mismatch or resonance shift without a Vector Network Analyzer. Blind tuning often leads to transmitter burnout.

Q: What are the acceptance criteria for antenna tuning and trimming? A: Typically, a Return Loss of $< -10\text{dB}$ across the entire bandwidth (e.g., 2.40–2.48 GHz for BLE) is the standard acceptance criterion.

Q: How does the solder mask affect antenna tuning and trimming? A: Solder mask has a higher dielectric constant than air. Applying it over an antenna trace lowers the resonant frequency and increases loss. It is best practice to remove solder mask (windowing) over the antenna element.

Q: Why is my antenna tuning changing after potting? A: Potting compounds have a high dielectric constant ($D_k \approx 3-5$). This drastically shifts frequency downward. You must perform antenna tuning and trimming after potting or simulate the potting effect during design.

Q: Does APTPCB offer antenna design services? A: APTPCB focuses on manufacturing. We provide DFM reviews to ensure your layout is manufacturable and that impedance lines are within tolerance, but the RF design and active tuning should be done by an RF engineer.

Q: What is the difference between "tuning" and "matching"? A: They are often used interchangeably. Strictly speaking, "tuning" adjusts the resonant frequency (reactance), while "matching" transforms the resistive part of the impedance to 50 Ohms. Both are accomplished simultaneously using a matching network.

Q: How do I specify antenna tuning requirements in my order? A: Include a note in your fabrication drawing: "Controlled Impedance required on Layer 1. Antenna trace width tolerance $\pm 10%$. Remove solder mask over antenna area."

Resources for antenna tuning and trimming

- Antenna PCB Manufacturing: Specific capabilities for printing antennas.

- High Frequency PCB: Details on materials like Rogers and Teflon.

- Impedance Calculator: Tool to estimate trace width for 50-ohm lines.

Antenna tuning and trimming glossary (key terms)

| Term | Definition |

|---|---|

| VSWR | Voltage Standing Wave Ratio. A measure of how efficiently RF power is transmitted. Ideal is 1:1. |

| Return Loss (S11) | The loss of power in the signal returned/reflected by a discontinuity in a transmission line. |

| Smith Chart | A graphical tool used to plot impedance and design matching networks. |

| Pi-Network | A configuration of three components (C-L-C or L-C-L) shaped like the Greek letter Pi, used for impedance matching. |

| Detuning | The shift of an antenna's resonant frequency away from the target due to environmental factors. |

| Keep-out Zone | An area on the PCB where no copper, components, or screws should be placed to avoid interference. |

| Dielectric Constant ($D_k$) | A measure of a material's ability to store electrical energy. Affects signal speed and antenna length. |

| Parasitic Capacitance | Unwanted capacitance between circuit elements that can alter tuning. |

| Feed Point | The point where the transmission line connects to the antenna structure. |

| Counterpoise | The conductive surface (ground plane) that functions as the other half of a monopole antenna. |

Request a quote for antenna tuning and trimming (Design for Manufacturability (DFM) review + pricing)

APTPCB provides precision manufacturing for RF designs, ensuring your antenna geometry and stackup meet strict specifications. Send us your design files for a comprehensive DFM review to catch potential tuning issues before production.

Checklist for Quote Request:

- Gerber Files: RS-274X format.

- Stackup Details: Specify material type (FR4, Rogers, etc.) and target thickness.

- Impedance Requirements: List specific traces requiring 50-ohm control.

- Volume: Prototype (5-10 pcs) or Mass Production.

Conclusion (next steps)

Antenna tuning and trimming is the bridge between a theoretical RF design and a functional wireless product. By strictly controlling PCB manufacturing tolerances, managing enclosure effects, and utilizing precise matching networks, engineers can ensure optimal range and battery life. Whether you are physically trimming a prototype or statistically tuning a production batch, success relies on a stable, high-quality PCB foundation.