Engineers designing real-time control systems for electric vehicles (EVs), ADAS test benches, or automated manufacturing lines often face a critical challenge: maintaining high-speed data integrity in harsh environments. An automotive-grade EtherCAT interface PCB requires more than just standard routing; it demands strict adherence to signal integrity rules, thermal management, and vibration resistance.

APTPCB (APTPCB PCB Factory) specializes in fabricating and assembling these high-reliability boards where microsecond latency and zero packet loss are non-negotiable. This guide covers the specific parameters, layout rules, and failure modes associated with automotive EtherCAT hardware.

automotive-grade EtherCAT interface PCB quick answer (30 seconds)

Designing a reliable EtherCAT interface for automotive environments involves strict control over the physical layer (PHY) and mechanical robustness.

- Impedance Control: Differential pairs (TX/RX) must be routed at 100Ω ±10%. Deviations cause signal reflection and CRC errors.

- Isolation Requirements: Automotive environments often require 1.5kV to 3kV galvanic isolation between the EtherCAT logic and the vehicle chassis ground to prevent ground loops.

- Component Grade: All active components (PHY transceivers, magnetics, processors) should meet AEC-Q100 or AEC-Q200 standards for temperature and stress.

- Connector Stability: Replace standard RJ45 jacks with M12 D-coded or X-coded connectors to withstand vibration (ISO 16750-3).

- EMI Mitigation: Use common-mode chokes and TVS diodes specifically rated for automotive transients (ISO 7637-2) on all data lines.

- PCB Material: Use High-Tg FR4 (Tg > 170°C) or specialized automotive laminates to prevent delamination during thermal cycling (-40°C to +125°C).

When automotive-grade EtherCAT interface PCB applies (and when it doesn’t)

Understanding the operational environment determines whether you need a standard industrial board or a specialized automotive-grade solution.

Applies when:

- In-Vehicle Testing: The PCB is mounted inside a moving vehicle for data logging or ADAS validation (Hardware-in-the-Loop).

- High Vibration Zones: The equipment is attached to robotic arms or stamping presses where G-forces exceed standard IT equipment limits.

- Extreme Temperatures: The device operates in unconditioned environments, such as outdoor charging stations or engine test cells (-40°C to 125°C).

- Safety-Critical Loops: The EtherCAT bus controls safety functions (e.g., emergency braking actuators) requiring ISO 26262 compliance.

- High EMI Noise: The system operates near high-voltage inverters or switching power supplies (common in EV powertrains).

Does not apply when:

- Controlled Server Rooms: The equipment sits in a climate-controlled rack with no vibration.

- Standard Office Automation: Simple data transfer where occasional packet loss is acceptable and retried by TCP/IP (EtherCAT is real-time UDP/Raw, so loss is critical).

- Low-Cost Consumer Gadgets: The cost of AEC-Q components and Class 3 manufacturing is unjustified for non-critical home devices.

- Static Lab Benches: If the environment is clean, temperature-stable, and vibration-free, a standard industrial-grade EtherCAT interface PCB is sufficient.

automotive-grade EtherCAT interface PCB rules and specifications (key parameters and limits)

The following table outlines the critical design rules for an automotive-grade EtherCAT interface PCB. Ignoring these parameters often leads to communication failures during EMC testing or field operation.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Differential Impedance | 100Ω ±10% | Matches PHY and cable impedance to minimize reflections. | TDR (Time Domain Reflectometry) test coupons. | Signal reflections, high Bit Error Rate (BER). |

| Pair-to-Pair Skew | < 1.6 ns (approx. 250mm) | Ensures TX and RX signals arrive within the sampling window. | Length matching in CAD tool. | Timing violations, link negotiation failure. |

| Intra-Pair Skew | < 10 mil (0.254 mm) | Maintains differential signaling balance to reject common-mode noise. | CAD constraint manager. | Increased EMI emission, susceptibility to noise. |

| Isolation Voltage | > 1500 Vrms | Protects low-voltage logic from high-voltage spikes in the vehicle chassis. | Hi-Pot testing during QA. | Component destruction, safety hazards. |

| Trace Width/Spacing | Calculated for 100Ω (e.g., 5/6 mil) | Defines the physical impedance profile. | Impedance Calculator | Incorrect impedance, signal loss. |

| Via Count on Diff Pairs | Max 2 per pair | Vias introduce impedance discontinuities (capacitive loading). | Visual inspection / Signal Integrity simulation. | Signal degradation at high frequencies. |

| Ground Reference | Solid continuous plane | Provides return path for high-speed signals. | Layer stackup review. | EMI radiation, poor signal integrity. |

| Magnetics Placement | < 25mm from connector | Minimizes the length of the "exposed" signal path. | Layout review. | Increased susceptibility to external noise. |

| ESD Protection | Contact ±8kV, Air ±15kV | Automotive environments are prone to static discharge. | ESD gun testing (ISO 10605). | PHY transceiver damage during handling or operation. |

| IPC Class | IPC-6012 Class 3 | Ensures high reliability (plating thickness, annular ring). | Cross-section analysis (microsection). | Early field failure due to thermal cycling or vibration. |

| Solder Mask Dam | > 4 mil | Prevents solder bridging on fine-pitch PHY chips. | DFM check. | Short circuits during assembly. |

automotive-grade EtherCAT interface PCB implementation steps (process checkpoints)

Designing and manufacturing these boards requires a structured workflow to ensure compliance with automotive standards.

Component Selection & BOM Scrub

- Action: Select PHYs (e.g., Beckhoff ET1100/ET1200 or Microchip LAN9252) and magnetics that are AEC-Q100/Q200 qualified.

- Check: Verify operating temperature ranges match the target environment (e.g., Grade 1: -40°C to +125°C).

Stackup Definition

- Action: Define layer stackup with APTPCB engineers to achieve 100Ω differential impedance on specific layers.

- Check: Confirm dielectric constant (Dk) and prepreg thickness support the required trace widths.

Schematic Design & Isolation Strategy

- Action: Implement galvanic isolation using transformers or capacitive isolators. Add TVS diodes on MDI lines.

- Check: Ensure the isolation barrier cuts across all layers (no copper crossing the gap).

Placement & Layout (Critical Phase)

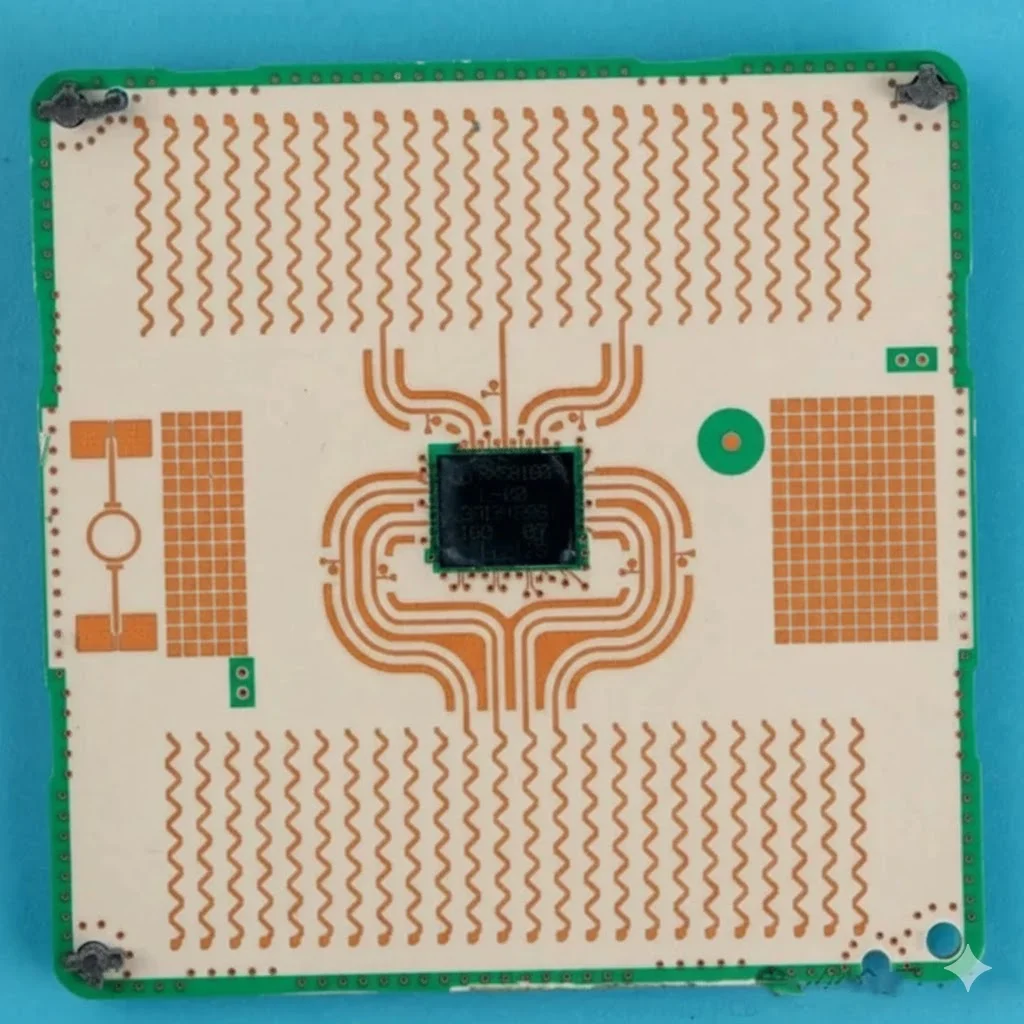

- Action: Place the PHY, magnetics, and connector in a straight line to minimize trace length. Route differential pairs first.

- Check: Verify no stubs on differential pairs and ensure continuous ground reference planes beneath them.

Power Integrity & Filtering

- Action: Place decoupling capacitors (0.1µF and 10µF) as close as possible to PHY power pins. Use ferrite beads to isolate PLL power.

- Check: Simulate PDN (Power Delivery Network) to ensure stable voltage during high current switching.

EMI/EMC Simulation

- Action: Simulate return paths and shield effectiveness.

- Check: Identify potential radiation loops before fabrication.

DFM & Fabrication

- Action: Submit Gerbers for Automotive Electronics PCB manufacturing.

- Check: Specify IPC Class 3 and TDR testing requirements in fabrication notes.

Assembly & Conformal Coating

- Action: Assemble using lead-free automotive-grade solder paste. Apply conformal coating (acrylic or silicone) if moisture is a risk.

- Check: Perform AOI and X-ray inspection on BGA/QFN packages.

Functional & Environmental Testing

- Action: Run EtherCAT conformance tests (CTT) and thermal cycling tests.

- Check: Verify zero packet loss during vibration testing.

automotive-grade EtherCAT interface PCB troubleshooting (failure modes and fixes)

Even with robust design, issues can arise during validation. Use this guide to diagnose common failures in automotive-grade EtherCAT interface PCB units.

Symptom 1: Intermittent Link Loss

- Possible Cause: Vibration causing momentary contact failure or impedance mismatch causing marginal signal quality.

- Check: Inspect connector solder joints (especially M12/RJ45). Use a TDR to check for impedance discontinuities >10%.

- Fix: Reflow connectors; adjust trace width in layout; switch to stranded patch cables for vibration zones.

Symptom 2: High CRC Error Count

- Possible Cause: EMI coupling from nearby motor drives or poor ground return path.

- Check: Verify if the error rate correlates with motor speed/load. Check for ground loops.

- Fix: Improve shielding; add common-mode chokes; ensure the shield of the EtherCAT cable is terminated correctly (usually to chassis ground via a capacitor).

Symptom 3: PHY Overheating / Thermal Shutdown

- Possible Cause: Inefficient linear regulators (LDO) dropping high voltage, or lack of thermal relief.

- Check: Measure case temperature with a thermal camera.

- Fix: Switch to a DC-DC buck converter; increase copper area connected to the PHY's thermal pad.

Symptom 4: Device Not Detected (Init State Stuck)

- Possible Cause: Incorrect EEPROM configuration or crystal oscillator startup failure.

- Check: Probe the crystal pins (carefully, low capacitance probe) to verify oscillation. Read EEPROM via I2C.

- Fix: Correct the EtherCAT Slave Information (ESI) file; replace crystal with an automotive-grade oscillator with higher drive strength.

Symptom 5: EMC Test Failure (Radiated Emissions)

- Possible Cause: Common-mode noise escaping through the cable shield or board edges.

- Check: Near-field probe scan of the PCB edges and connector area.

- Fix: Add stitching vias around the board edge (Faraday cage); improve common-mode filtering on the MDI lines.

Symptom 6: Physical Damage to Components

- Possible Cause: Board flexure during installation or thermal expansion mismatch.

- Check: Look for cracked MLCC capacitors or solder joint fractures.

- Fix: Move components away from mounting holes/V-score lines; use soft-termination capacitors.

How to choose automotive-grade EtherCAT interface PCB (design decisions and trade-offs)

When selecting or designing an automotive-grade EtherCAT interface PCB, engineers must balance performance, cost, and durability.

1. Connector Type: RJ45 vs. M12

- RJ45: Standard, cheap, easy to debug. Risk: Poor vibration resistance; contacts can fret and fail in vehicles.

- M12 (D-coded/X-coded): Waterproof (IP67), vibration-proof. Trade-off: Higher cost, requires specialized cables. Recommendation: Always use M12 for in-vehicle or chassis-mounted units.

2. PCB Material: Standard FR4 vs. Automotive Laminates

- Standard FR4 (Tg 130-140°C): Low cost. Risk: Softens at high temps, leading to via barrel cracks.

- High-Tg FR4 (Tg 170°C+): Essential for automotive under-hood applications. Trade-off: Slightly harder to drill, higher material cost.

3. Layer Count: 2-Layer vs. 4-Layer+

- 2-Layer: Very difficult to control impedance and contain EMI. Risk: High failure rate in EMC testing.

- 4-Layer (Sig/Gnd/Pwr/Sig): Provides solid reference planes. Trade-off: Higher manufacturing cost. Recommendation: Minimum 4 layers for any High-Speed PCB with EtherCAT.

4. Manufacturing Class: Class 2 vs. Class 3

- Class 2: Standard electronics.

- Class 3: High reliability (aerospace/automotive). Requires stricter plating and inspection. Recommendation: Class 3 for safety-critical or inaccessible units.

automotive-grade EtherCAT interface PCB FAQ (cost, lead time, common defects, acceptance criteria, Design for Manufacturability (DFM) files)

Q: How much does an automotive-grade EtherCAT interface PCB cost compared to a standard one? A: Expect a 30-50% premium. This covers AEC-Q components, High-Tg materials, Class 3 manufacturing controls, and additional testing (TDR, ionic contamination).

Q: What is the typical lead time for these boards? A: Prototype fabrication takes 5-7 days. Full turnkey assembly can take 3-5 weeks, primarily driven by the sourcing lead time for specialized automotive connectors and PHY chips.

Q: What are the most common defects found in these PCBs? A: Impedance mismatch (due to incorrect stackup), solder joint fractures (vibration), and ionic contamination (causing dendritic growth in humid environments).

Q: What acceptance criteria should I specify? A: Specify IPC-6012 Class 3 for fabrication and IPC-A-610 Class 3 for assembly. Require TDR reports for all differential pairs and a Certificate of Conformance (CoC) for materials.

Q: Can I use standard Ethernet magnetics? A: No. Automotive Ethernet/EtherCAT requires magnetics with higher isolation and common-mode rejection ratios, often tested to stricter vibration and temperature standards.

Q: What files does APTPCB need for a DFM review? A: Gerber files (RS-274X), Drill files, IPC-356 (Netlist), Layer Stackup details (material, thickness), and Assembly drawings (XY coordinates, rotation).

Q: How do I validate the signal integrity before manufacturing? A: Perform post-layout simulation using IBIS models of your EtherCAT PHY. APTPCB can also assist with stackup verification using our Impedance Calculator.

Resources for automotive-grade EtherCAT interface PCB (related pages and tools)

- Automotive Electronics PCB: Overview of our capabilities in the automotive sector.

- High-Speed PCB: Detailed capabilities for impedance-controlled boards.

- PCBA Turnkey Assembly: Full service from PCB fabrication to component sourcing and assembly.

- Impedance Calculator: Tool to calculate trace width and spacing for 100Ω differential pairs.

automotive-grade EtherCAT interface PCB glossary (key terms)

| Term | Definition |

|---|---|

| EtherCAT | Ethernet for Control Automation Technology; a high-performance, real-time industrial Ethernet protocol. |

| PHY (Physical Layer) | The chip that interfaces the digital link layer controller with the physical medium (cable). |

| MDI (Medium Dependent Interface) | The physical port (connector and magnetics) connecting the PCB to the network cable. |

| Differential Impedance | The impedance between two conductors in a differential pair, critical for signal integrity (target 100Ω). |

| AEC-Q100 | Failure mechanism-based stress test qualification for packaged integrated circuits in automotive applications. |

| TDR (Time Domain Reflectometry) | A measurement technique used to determine the impedance characteristics of PCB traces. |

| Skew | The time difference between the arrival of signals on two different lines (e.g., intra-pair or inter-pair). |

| Galvanic Isolation | Separating electrical circuits to prevent current flow between them, usually via transformers or optocouplers. |

| Common Mode Choke | An inductor used to block higher-frequency alternating current (noise) while passing direct current (signals). |

| IPC-6012 Class 3 | Performance specification for high-reliability rigid printed boards (automotive, aerospace, medical). |

Request a quote for automotive-grade EtherCAT interface PCB

Ready to move your design from prototype to production? APTPCB provides comprehensive DFM reviews to catch impedance and layout issues before manufacturing begins.

To get an accurate quote, please prepare:

- Gerber Files: Including all copper, solder mask, and silk layers.

- Stackup Requirements: Desired material (Tg), thickness, and impedance constraints.

- BOM (Bill of Materials): If requesting assembly, highlight any specific AEC-Q components.

- Volume & Lead Time: Prototype quantity vs. mass production targets.

Conclusion (next steps)

Developing a robust automotive-grade EtherCAT interface PCB requires a disciplined approach to signal integrity, material selection, and manufacturing quality. By adhering to strict impedance rules, utilizing automotive-qualified components, and validating designs against harsh environmental standards, engineers can ensure reliable real-time communication in the most demanding vehicle and industrial applications. APTPCB is equipped to support these high-reliability requirements with precision fabrication and assembly services.