automotive iatf linkage: what this playbook covers (and who it’s for)

This playbook addresses the critical gap between holding an automotive quality certificate and actually applying it to a specific printed circuit board (PCB) order. We define automotive iatf linkage as the operational connection between your specific design requirements and the supplier’s IATF 16949 Quality Management System. Often, buyers assume that because a factory is IATF certified, every board produced automatically meets automotive standards. In reality, without explicit linkage—defined through control plans, PPAP (Production Part Approval Process), and specific fabrication notes—an "automotive" order may be processed on a standard commercial line.

This guide is written for Procurement Managers, Sourcing Engineers, and Supplier Quality Engineers (SQEs) who need to ensure their automotive electronics are manufactured with genuine traceability and process control. It moves beyond the theoretical definitions of quality standards and focuses on the transactional steps required to enforce them. You will learn how to specify requirements that trigger IATF protocols, how to validate that those protocols are active, and how to audit a supplier’s capability effectively.

At APTPCB (APTPCB PCB Factory), we see the difference between successful automotive launches and stalled projects often comes down to how clearly this linkage is established during the RFQ phase. This document serves as a decision-making framework. It helps you navigate the trade-offs between cost, speed, and compliance, ensuring that your risk management strategy is built into the hardware itself, not just the paperwork.

When automotive iatf linkage is the right approach (and when it isn’t)

Understanding the scope of this playbook requires knowing when to enforce full automotive protocols and when standard manufacturing suffices.

automotive iatf linkage is mandatory when:

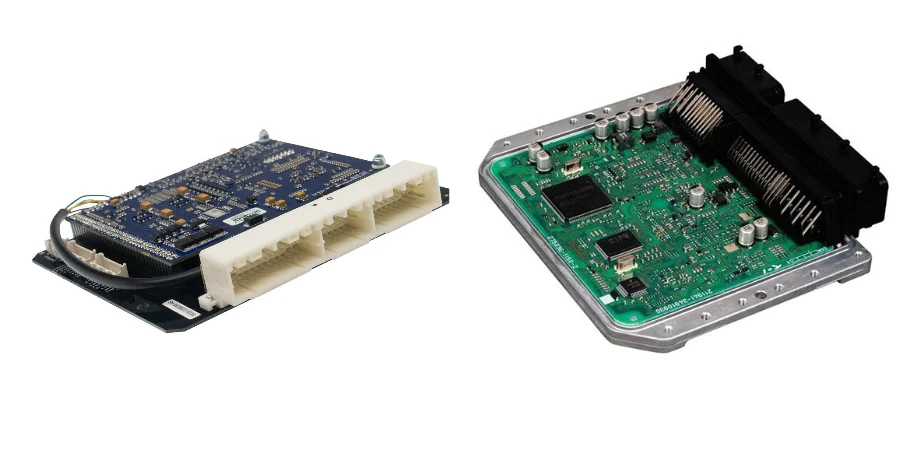

- Safety-Critical Systems: The PCB is part of ABS, airbag deployment, ADAS (Advanced Driver Assistance Systems), or steering controls. Failure here endangers life; full traceability down to the raw material batch is non-negotiable.

- Harsh Environments: The component sits under the hood (ECU), near the transmission, or in wheel wells where thermal cycling, vibration, and chemical exposure are constant.

- Long-Term Reliability: The vehicle warranty extends 10+ years. The PCB must resist conductive anodic filament (CAF) growth and solder joint fatigue over a decade of use.

- Regulatory Compliance: You are required to submit IMDS (International Material Data System) data or meet specific OEM customer specific requirements (CSRs).

It may be overkill when:

- Non-Functional Prototypes: You are testing form and fit only, not electrical performance or durability.

- Aftermarket Accessories: Non-integrated gadgets (e.g., generic USB chargers) that do not interface with the vehicle’s CAN bus or safety systems.

- Consumer Electronics: If you are building a standard remote control or a toy, the overhead of PPAP and APQP (Advanced Product Quality Planning) adds unnecessary cost and lead time.

Specs & requirements (before quoting)

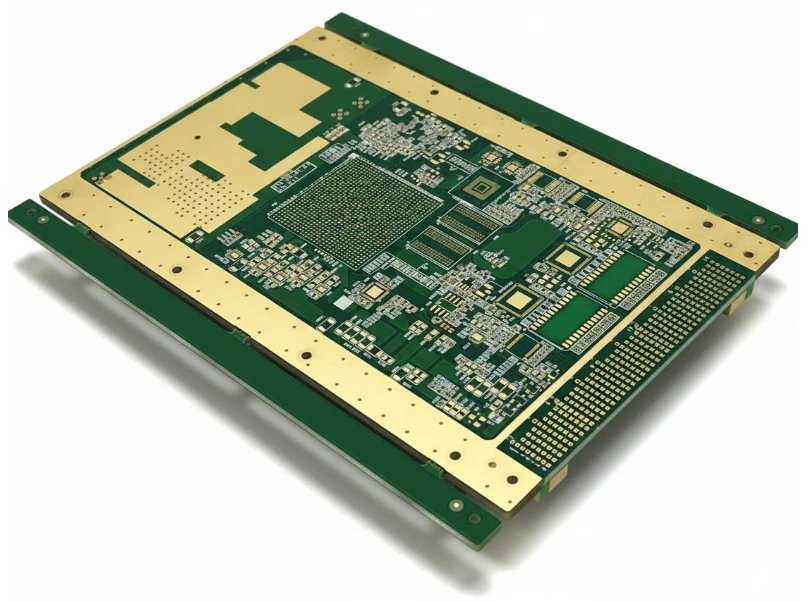

Once you have determined that automotive iatf linkage is necessary for your project, you must translate this intent into concrete engineering specifications. Vague notes like "Build to IPC Class 3" are insufficient for modern automotive supply chains. You must provide specific parameters that force the manufacturer to select the correct materials and process flows.

Define the following 10 requirements clearly in your fabrication drawing or technical specification document:

- Base Material Grade: Specify "Automotive Grade" laminate. Do not just say "FR4." Specify High-Tg (e.g., Tg > 170°C) and Low-CTE (Coefficient of Thermal Expansion) to withstand thermal shock.

- CTI (Comparative Tracking Index): Explicitly request CTI ≥ 600V (PLC 0) if the board handles high voltage or is in a humid environment, to prevent electrical arcing.

- Cleanliness Standards: Set a limit for ionic contamination, typically < 1.56 µg/cm² of NaCl equivalent, to prevent electrochemical migration.

- Solder Mask Specs: Require adherence to IPC-SM-840 Class H (High reliability). Specify that the mask must be resistant to automotive fluids (oil, fuel, brake fluid).

- Copper Plating Thickness: For power distribution, specify minimum hole wall copper (e.g., average 25µm, min 20µm) to ensure barrel integrity during thermal expansion.

- IPC Classification: State "IPC-6012 Class 3" for performance requirements. This dictates tighter tolerances on annular rings and plating voids.

- Traceability Level: Demand laser marking on individual PCBs (QR code or Datamatrix) containing the date code, lot number, and panel ID.

- PPAP Level: Define the submission level required (usually Level 3 for new automotive parts). This forces the supplier to generate a Control Plan and PFMEA.

- IMDS Registration: Require the supplier to upload material data to the IMDS database and provide the ID number before mass production.

- Solderability: Specify J-STD-003 compliance, ensuring the finish (e.g., ENIG, Immersion Silver) remains solderable after defined storage periods (aging tests).

Hidden risks (root causes & prevention)

Even with perfect specifications, the automotive iatf linkage can be broken by operational realities on the factory floor. These are "hidden" risks because they often don't show up in a standard audit but manifest as failures during mass production ramp-up.

1. Sub-tier Material Substitution

- Risk: The laminate supplier runs out of the specified "Brand A" automotive resin and substitutes "Brand B" with similar specs but different curing behaviors.

- Why it happens: Supply chain pressure and lack of locked BOMs at the raw material level.

- Detection: FTIR (Fourier Transform Infrared Spectroscopy) analysis on incoming raw materials.

- Prevention: Mandate a "No Change" policy on the laminate brand and type without prior PCN (Product Change Notification).

2. The "Golden Sample" Trap

- Risk: Prototypes are built on a dedicated engineering line, but mass production moves to a high-speed line with different chemical baths.

- Why it happens: Factories optimize for throughput in volume production.

- Detection: Discrepancies in microsection analysis between prototype and pilot run.

- Prevention: Require the "Safe Launch" plan where the pilot run uses the exact equipment intended for mass production.

3. Incomplete Curing of Solder Mask

- Risk: Solder mask peels or blisters under harsh thermal cycling.

- Why it happens: Rushing the UV bump or thermal cure process to clear bottlenecks.

- Detection: Solvent rub tests (MEK test) and tape tests per IPC-TM-650.

- Prevention: Audit the oven profiles and ensure cure times are logged automatically.

4. Drill Smear in High-Density Interconnects

- Risk: Intermittent open circuits in vias due to resin smear blocking the copper connection.

- Why it happens: Drill bits are overused (exceeding hit count) or desmear chemistry is weak.

- Detection: Microsectioning of the most complex via structures on the panel.

- Prevention: Enforce strict drill bit life management and automated dosing for desmear lines.

5. Traceability Gaps in Rework

- Risk: A PCB fails E-test, is manually repaired, and re-enters the line without a log entry.

- Why it happens: Operators trying to keep yield numbers high.

- Detection: Visual inspection often misses this; requires data log analysis.

- Prevention: Configure E-test machines to lock out failed serial numbers until authorized by a Quality Engineer.

6. Plating Voids in High Aspect Ratio Holes

- Risk: Thin plating in the center of deep holes leads to barrel cracks.

- Why it happens: Inadequate agitation or throwing power in the plating tank for thick boards.

- Detection: Thermal shock testing followed by resistance measurement.

- Prevention: Use aspect ratio-specific plating racks and flight bars with vibration.

7. CAF (Conductive Anodic Filament) Growth

- Risk: Short circuits developing internally over months of operation.

- Why it happens: Micro-cracks in the resin or poor glass-to-resin bonding allow moisture ingress.

- Detection: CAF testing (1000 hours at high voltage/humidity).

- Prevention: Use CAF-resistant materials and optimize drilling feeds/speeds to prevent wicking.

8. Handling Damage (ESD)

- Risk: Latent damage to the PCB substrate or embedded components.

- Why it happens: Poor grounding in the final inspection or packaging area.

- Detection: Often impossible to detect on bare boards; fails at assembly.

- Prevention: Strict ESD protocols and periodic audits of grounding straps and flooring.

Validation plan (what to test, when, and what “pass” means)

To secure the automotive iatf linkage, you cannot rely solely on the supplier's Certificate of Conformance (CoC). You need a validation plan that verifies the product meets the intent of the design. This plan should be executed during the NPI (New Product Introduction) phase and periodically during mass production.

1. Electrical Continuity & Isolation (100%)

- Objective: Ensure no opens or shorts.

- Method: Flying probe (for prototypes) or Bed of Nails (for volume).

- Acceptance: 100% Pass. No manual repairs allowed for safety-critical paths.

2. Microsection Analysis (Per Lot)

- Objective: Verify internal structural integrity.

- Method: Cross-sectioning coupons from the panel edge.

- Acceptance: Copper thickness meets spec, no plating cracks, registration within tolerance, dielectric thickness correct.

3. Thermal Shock Test (Periodic)

- Objective: Simulate rapid temperature changes in the vehicle.

- Method: -40°C to +125°C (or higher), 500+ cycles.

- Acceptance: Change in resistance < 10%. No delamination or barrel cracks.

4. Solderability Test (Per Lot)

- Objective: Ensure the PCBA process will be successful.

- Method: Dip and look / Wetting balance test.

- Acceptance: > 95% wetting coverage. No dewetting or non-wetting.

5. Ionic Contamination Test (Per Lot)

- Objective: Prevent corrosion and electrochemical migration.

- Method: ROSE test (Resistivity of Solvent Extract) or Ion Chromatography.

- Acceptance: < 1.56 µg/cm² NaCl equivalent (or customer specific limit).

6. Dimensional Verification (First Article)

- Objective: Confirm physical fit.

- Method: CMM (Coordinate Measuring Machine) or optical measurement.

- Acceptance: All dimensions within tolerance. Cpk > 1.33 for critical dimensions.

7. Interconnect Stress Test (IST) (Qualification)

- Objective: Accelerated life testing of vias.

- Method: Thermal cycling of specific test coupons until failure.

- Acceptance: Cycles to failure must exceed the industry standard for the specific application class.

8. Impedance Control (Batch)

- Objective: Signal integrity for high-speed data (CAN-FD, Ethernet).

- Method: TDR (Time Domain Reflectometry) on test coupons.

- Acceptance: Within ±10% (or ±5%) of target impedance.

Supplier checklist (RFQ + audit questions)

Use this checklist to vet potential partners. A supplier capable of true automotive iatf linkage will answer these questions with data, not just "yes."

Group 1: RFQ Inputs (What you send)

- Gerber files (RS-274X or X2) with clear layer stackup.

- IPC Netlist (IPC-356) for electrical test comparison.

- Fabrication drawing referencing IPC-6012 Class 3.

- Material specification sheet (Slash sheet references).

- Panelization requirements (fiducials, tooling holes).

- Special process requirements (e.g., edge plating, via-in-pad).

- Volume projections (EAU) to determine tooling strategy.

- Packaging requirements (ESD bags, humidity indicators).

Group 2: Capability Proof (What they provide)

- Valid IATF 16949 Certificate (check expiration and scope).

- Equipment list showing automated optical inspection (AOI) capacity.

- Demonstrated capability for the required aspect ratio (e.g., 10:1).

- In-house lab capabilities (Microsection, Thermal shock, X-ray).

- Examples of similar automotive parts produced (redacted is fine).

- DFM report sample showing how they catch design issues.

Group 3: Quality System & Traceability

- Do they use a computerized MES (Manufacturing Execution System)?

- Can they trace a specific board back to the raw material lot?

- Is there a "Safe Launch" or "Early Production Containment" process?

- How are non-conforming materials quarantined and scrapped?

- Are operators certified for IPC-A-600 inspection?

- Is there a documented calibration schedule for all measurement tools?

Group 4: Change Control & Delivery

- Is there a formal PCN (Product Change Notification) agreement?

- What is the policy on sub-contracting processes (e.g., surface finish)?

- Do they have a Business Continuity Plan (disaster recovery)?

- How is buffer stock managed for automotive fluctuations?

- What is the standard response time for a corrective action report (8D)?

- Do they support EDI (Electronic Data Interchange) for orders?

Decision guidance (trade-offs you can actually choose)

Enforcing automotive iatf linkage involves trade-offs. You cannot maximize every parameter simultaneously. Here is how to navigate the common decision points.

1. Reliability vs. Cost (Class 2 vs. Class 3)

- If you prioritize absolute reliability for safety systems, choose IPC Class 3. It requires more copper, stricter plating controls, and more inspection.

- Otherwise, choose IPC Class 2 for infotainment or non-critical cabin electronics. It is significantly cheaper and faster to produce.

2. Speed vs. Compliance (Quick Turn vs. PPAP)

- If you prioritize getting prototypes to the lab next week, choose a "Standard Spec" quick turn without full PPAP.

- Otherwise, choose a standard lead time (3-4 weeks) to allow for the full APQP process, tooling verification, and documentation generation required for the production part approval.

3. Material Performance vs. Availability

- If you prioritize extreme thermal endurance, choose a specialized automotive laminate (e.g., Rogers or high-end Isola). Be prepared for longer lead times.

- Otherwise, choose a standard High-Tg FR4 from a major vendor (like Shengyi or Kingboard) that is readily stocked, provided it meets your basic Tg and CTI requirements.

4. Density vs. Yield (HDI vs. Through-Hole)

- If you prioritize miniaturization for a compact ECU, choose HDI (High Density Interconnect) with microvias.

- Otherwise, choose standard through-hole technology if space allows. It is more robust, easier to inspect, and has a lower risk of latent defects in the field.

5. Local Support vs. Global Scale

- If you prioritize rapid engineering changes and DFM collaboration, choose a supplier with strong local engineering support or a dedicated aptpcb compliance service team.

- Otherwise, choose a pure-play high-volume factory if the design is frozen and cost is the only driver.

FAQ

Q: What is the main difference between ISO 9001 and IATF 16949 for PCBs? A: ISO 9001 is a general quality management system. IATF 16949 adds specific automotive requirements like defect prevention, reduction of variation, and supply chain waste reduction, focusing heavily on risk management (FMEA).

Q: Can I use standard FR4 for automotive applications? A: It depends on the application. For non-critical cabin electronics, standard FR4 might work. For under-hood applications, you typically need High-Tg, halogen-free, or high-CTI materials to withstand heat and voltage.

Q: What is a PPAP and why do I need it? A: PPAP (Production Part Approval Process) is a data submission that proves the supplier can meet your specs at the quoted production rate. It prevents "lucky" prototypes from masking mass production issues.

Q: Why is CTI (Comparative Tracking Index) critical for EVs? A: Electric vehicles operate at higher voltages. A low CTI material can carbonize and create a conductive path (track) between traces, leading to shorts and potential fires.

Q: How does APTPCB handle automotive traceability? A: APTPCB utilizes a comprehensive MES that links every production step to the specific panel ID, ensuring full backward traceability to raw materials and forward traceability to shipping lots.

Q: Is "Aviation AS9100 PCB" the same as Automotive IATF? A: No, but they are related. Aviation AS9100 PCB standards focus heavily on configuration management and documentation for aerospace, while IATF focuses on process capability and continuous improvement for high-volume automotive production.

Q: What is the "Safe Launch" plan? A: It is a period of intensified inspection (often 200% visual or increased sampling) during the initial production ramp-up to catch any issues before they escape to the customer.

Q: Can I skip the E-test for cost savings? A: Never for automotive. Electrical testing is the final gatekeeper for opens and shorts. Skipping it breaks the IATF linkage and exposes you to massive liability.

Related pages & tools

- Automotive Electronics PCB – Explore specific capabilities for engine control units, infotainment, and safety systems.

- PCB Quality System – Deep dive into the certifications and quality control methodologies used to maintain high standards.

- First Article Inspection – Understand the detailed verification process that validates the manufacturing setup before volume runs.

- Isola PCB Materials – Review technical data on high-performance laminates often required for automotive thermal reliability.

- Heavy Copper PCB – Learn about solutions for high-power distribution in electric vehicle battery management systems.

- DFM Guidelines – Access design rules that help ensure your board is manufacturable and compliant from the start.

Request a quote

Ready to validate your design for automotive production? At APTPCB, we provide a comprehensive DFM review alongside your quote to identify potential compliance risks early.

To get an accurate DFM and Quote, please provide:

- Gerber Files: RS-274X or X2 format.

- Fabrication Drawing: Including stackup, material specs, and IPC class.

- Volume: Prototype quantity and estimated annual usage (EAU).

- Special Requirements: PPAP level, IMDS, or specific testing needs.

Conclusion

Establishing a robust automotive iatf linkage is not about collecting certificates; it is about engineering a supply chain that is resilient, traceable, and compliant by design. By defining clear requirements, understanding the hidden risks of scale-up, and enforcing a rigorous validation plan, you transform your PCB procurement from a commodity purchase into a strategic safety asset. Whether you are building the next generation of EV power systems or critical safety sensors, the steps outlined in this playbook provide the roadmap to secure, scalable manufacturing.