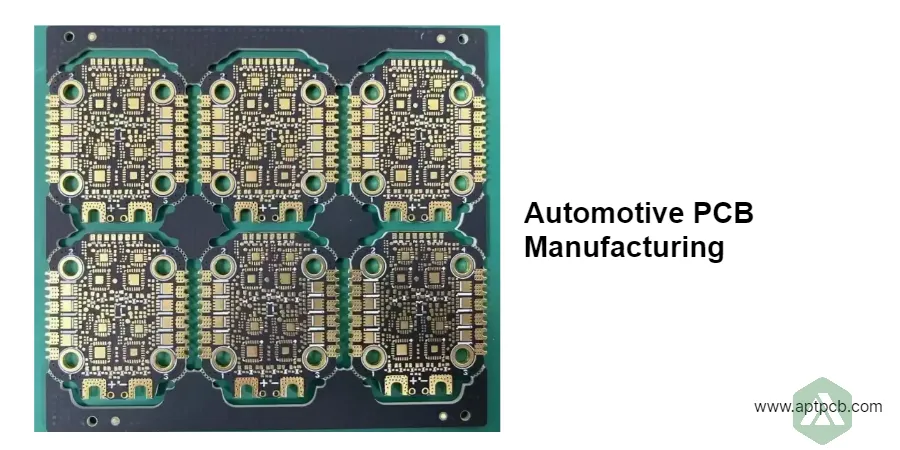

Automotive PCB manufacturing supports vehicle electronics requiring AEC-Q200 qualified components, extended temperature operation (-40 to +125°C), functional safety per ISO 26262, and 15+ year reliability across ADAS sensors, infotainment systems, powertrain controllers, and body electronics demanding robust construction surviving vibration, thermal cycling, and harsh environments throughout vehicle lifecycles with zero-defect expectations in safety-critical applications.

At APTPCB, we manufacture automotive PCBs with automotive electronics expertise implementing qualified processes, validated materials, and comprehensive testing supporting ADAS through powertrain applications.

Achieving AEC-Q Qualification and Automotive Standards

Automotive components require AEC-Q100 (ICs) and AEC-Q200 (passives) qualification validating reliability through extreme temperature cycling, humidity testing, and mechanical stress. Qualification challenges include extended temperature ranges (-40 to +150°C junction), qualification sample sizes, and long-term reliability validation. Inadequate qualification causes field failures from thermal stress, premature wear-out, or environmental degradation — significantly impacting warranty costs and brand reputation.

At APTPCB, our manufacturing implements automotive-qualified processes achieving long-term reliability.

Automotive Qualification Implementation

- AEC-Q Qualified Components: Complete automotive supply chain with qualified passives, semiconductors, and connectors through quality system supplier management.

- Extended Temperature Validation: Testing from -40 to +125°C confirming operation across automotive temperature specifications.

- Thermal Cycling: >1000 cycles validating solder joint reliability and preventing thermal fatigue failures.

- Vibration Testing: Random and sinusoidal vibration per automotive standards confirming mechanical robustness.

- Humidity and Corrosion: HAST and salt spray testing validating long-term environmental reliability.

Automotive Quality Standards

Through automotive-qualified manufacturing and comprehensive validation coordinated with NPI assembly development, APTPCB delivers automotive PCBs meeting industry reliability requirements.

Implementing Functional Safety per ISO 26262

Safety-critical automotive systems (ADAS, braking, steering) require functional safety implementation per ISO 26262 achieving ASIL-B through ASIL-D ratings through redundancy, diagnostics, and safe-state management. Safety challenges include implementing hardware safety mechanisms, achieving >90% diagnostic coverage, and validating systematic capability. Inadequate safety implementation prevents certification, causes liability exposure, or creates actual safety hazards — significantly impacting product viability in ADAS and autonomous vehicle markets.

At APTPCB, our manufacturing supports functional safety designs achieving ASIL compliance.

Functional Safety Implementation

- Redundant Architecture: Dual processors, sensors, or power supplies enabling continued operation despite single faults.

- Diagnostic Coverage: Self-test routines and hardware monitors detecting >90% of potential faults per ASIL requirements.

- Safe-State Management: Controlled shutdown or degraded operation during detected faults preventing unsafe conditions.

- Development Process Compliance: ISO 26262 design practices, DFMEA, and validation per automotive safety standards.

- Systematic Capability: Manufacturing processes achieving required failure rates and avoiding systematic errors.

Through functional safety expertise and validated processes, APTPCB enables safety-critical automotive applications achieving ISO 26262 compliance.

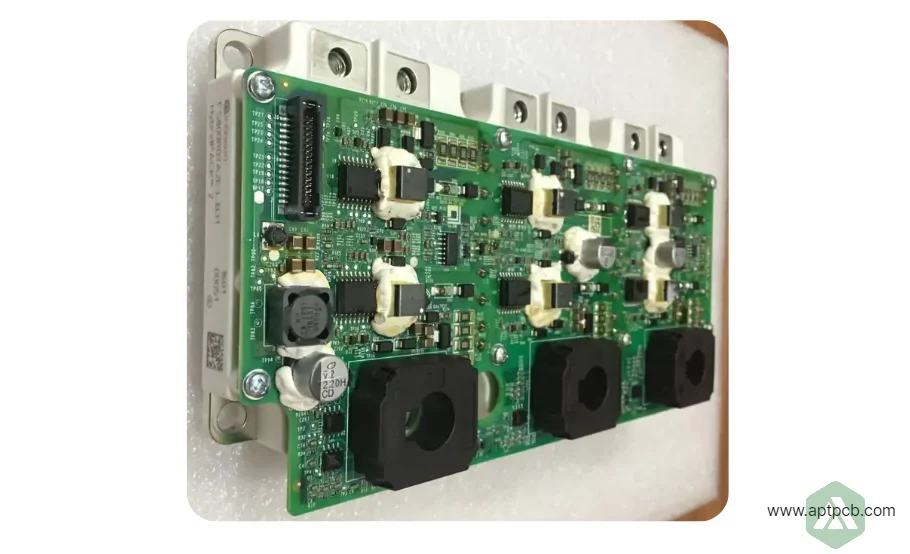

Supporting ADAS and Autonomous Vehicle Applications

Advanced driver assistance and autonomous vehicles integrate radar, cameras, lidar, and sensor fusion requiring high-speed data processing, automotive Ethernet networking, and functional safety. ADAS challenges include sensor data synchronization, deterministic processing latency, and redundant architecture for fail-operational systems. Inadequate ADAS implementation affects system performance, prevents safety certification, or limits autonomous capability — significantly impacting competitiveness in automated driving markets.

At APTPCB, we support ADAS manufacturing with specialized processes and validation.

ADAS Implementation Support

Sensor Processing Platforms

- High-performance processors (NVIDIA, Qualcomm, TI) executing neural networks and sensor fusion algorithms.

- Automotive Ethernet (100/1000BASE-T1) connecting sensors to central compute platforms.

- Power-over-Ethernet delivering power to distributed cameras and sensors.

- Thermal management for AI accelerators dissipating 20-50W in compact enclosures.

Fail-Operational Architecture

- Redundant processors and sensors enabling continued operation despite single failures.

- Diverse processing paths using different algorithms reducing common-mode failures.

- Health monitoring and degradation detection enabling predictive maintenance.

Through ADAS-optimized manufacturing coordinated with mass production scalability, APTPCB enables autonomous vehicle platforms.

Providing Long-Term Automotive Lifecycle Support

Automotive programs require 15+ year lifecycle support maintaining component availability, supporting field updates, and providing warranty support. Lifecycle challenges include component obsolescence, design change management, and field failure analysis. Inadequate lifecycle support causes supply interruptions, expensive last-time buys, or inability to support field repairs — significantly impacting total cost of ownership and customer satisfaction.

At APTPCB, we provide comprehensive automotive lifecycle support throughout vehicle production.

Lifecycle Support Capabilities

- Long-Term Component Availability: Automotive-grade components with extended availability commitments.

- Obsolescence Management: Proactive monitoring and alternative component qualification before availability issues.

- Design Change Control: Rigorous change management validating modifications maintaining form, fit, and function.

- Field Failure Analysis: Root cause analysis and corrective action preventing recurrence.

- Production Part Approval: PPAP documentation supporting automotive supply chain requirements.

Through comprehensive lifecycle support and automotive expertise, APTPCB enables successful automotive electronics programs from development through end-of-life.