Contents

- The Context: What Makes Beacon Light PCB Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Beacon Light PCB (What to Send)

- Conclusion

"Good" performance in this domain is defined by thermal equilibrium and mechanical resilience. A well-engineered Beacon Light PCB ensures that the LEDs operate within their safe junction temperature limits to prevent color shift or premature burnout, while simultaneously withstanding the vibration and voltage spikes common in automotive and industrial environments.

Highlights

- Thermal Management is Critical: The primary failure mode for beacon lights is overheating; substrate choice (Aluminum vs. FR4) dictates longevity.

- Current Handling: High-brightness LEDs require robust copper weights and careful trace width calculations to minimize voltage drop.

- Environmental Protection: These boards often live in harsh outdoor conditions, requiring specific surface finishes and conformal coatings.

The Context: What Makes Beacon Light PCB Challenging

Designing a PCB for a beacon light seems straightforward—connect LEDs to power—until you consider the operating environment. These boards are frequently deployed in "always-on" or high-frequency strobe applications. The rapid cycling of power creates thermal fatigue, expanding and contracting the board materials thousands of times.

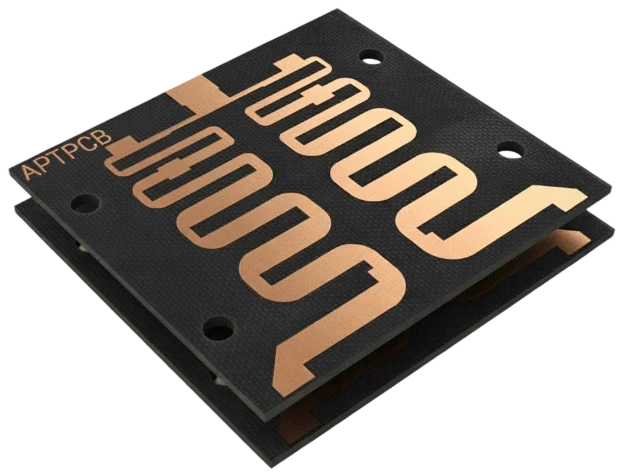

Furthermore, space is often constrained. A rotating beacon or a sleek aerodynamic light bar leaves little room for bulky heatsinks. The PCB itself must act as the primary thermal path. Manufacturers like APTPCB (APTPCB PCB Factory) often see designs fail not because the circuit logic was wrong, but because the stack-up could not transfer heat fast enough from the LED thermal pad to the ambient air.

Cost pressure is the final constraint. While a copper-base PCB offers the best performance, the market often demands the lower price point of aluminum or enhanced FR4. Balancing these physical realities with budget constraints is the central challenge of Beacon Light PCB fabrication.

The Core Technologies (What Actually Makes It Work)

To handle the demands of high-intensity lighting, several core technologies must converge on a single board.

Metal Core PCB (MCPCB) Substrates: The standard for beacon lights is the Metal Core PCB. By laminating a copper circuit layer onto a metal backing (usually aluminum) with a thin, thermally conductive dielectric, the board becomes a highly efficient heat spreader. This lowers the thermal resistance significantly compared to standard FR4.

Heavy Copper Traces: Beacon lights often draw significant current, especially in 12V or 24V automotive systems. Using Heavy Copper PCB technology (2oz, 3oz, or more) ensures that traces do not overheat and that voltage drop does not cause dimming in LEDs furthest from the connector.

Direct Thermal Path (DTP): In advanced designs, the dielectric layer under the LED thermal pad is removed, allowing the LED to be soldered directly to the metal base. This eliminates the thermal bottleneck of the dielectric layer, crucial for LEDs running at 3W or higher.

Transient Voltage Suppression: The circuitry must include robust protection against "load dump" events—sudden voltage spikes that occur in vehicle alternators. This is often integrated directly onto the PCB layout near the power entry point.

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

A Beacon Light PCB does not exist in a vacuum. It is part of a larger assembly ecosystem that dictates many design choices.

The Assembly Process: The assembly of these boards requires precise control. SMT Assembly for high-power LEDs is sensitive to voiding. If the solder paste under the thermal pad has voids (air pockets), heat cannot escape, creating hot spots that kill the LED. X-ray inspection is often necessary to verify void percentages are below 15-20%.

Housing and Enclosure: The PCB shape is rarely a simple rectangle. It is often circular or annular to fit inside a dome, or long and thin for a light bar. The mounting holes must align perfectly with the chassis to ensure the metal back of the PCB presses firmly against the housing for secondary heat dissipation.

Interconnects: Reliability extends to the connectors. Wire-to-board connectors must be rated for high vibration. In some sealed units, wires are soldered directly to pads to eliminate connector failure points, requiring large pads and strain relief holes in the PCB design.

Comparison: Common Options and What You Gain / Lose

Engineers often face a choice between material cost and thermal performance. Is standard FR4 enough, or is a metal core required? The decision impacts the beacon's brightness capability and lifespan.

Here is how the common technical choices translate into practical outcomes:

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| FR4 with Thermal Vias | Lowest cost; suitable only for low-power indicator beacons or accent lights. Poor heat transfer for high-power LEDs. |

| Aluminum MCPCB (1-2W/mK) | Industry standard. Good balance of cost and performance. Handles typical 1W-3W LEDs effectively. |

| Copper Base MCPCB | High cost, extreme performance. Used in aviation strobes or mining equipment where failure is not an option. |

| Rigid-Flex Construction | Allows 3D installation in curved light bars. Complex to manufacture but eliminates wiring harnesses between LED modules. |

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

To ensure a Beacon Light PCB survives in the field, the design must satisfy specific pillars of reliability. It is not enough to just light up; it must stay lit under stress.

Thermal Reliability: The junction temperature ($T_j$) of the LED is the governing metric. The PCB design must keep $T_j$ below the manufacturer's limit (usually 125°C or 150°C) even when the ambient temperature is 50°C or higher. This requires verifying the thermal conductivity of the dielectric layer.

Electrical Robustness: For automotive applications, the PCB must handle voltage fluctuations from 9V to 32V. Trace spacing needs to account for potential arcing if moisture ingress occurs, although conformal coating usually mitigates this.

Surface Finish: PCB Surface Finishes matter. HASL (Hot Air Solder Leveling) is common and robust, but for fine-pitch LED drivers or perfectly flat thermal pads, ENIG (Electroless Nickel Immersion Gold) is preferred to ensure even solder paste deposition.

| Feature | Acceptance Criteria | Why it Matters |

|---|---|---|

| Dielectric Breakdown | > 3000V AC | Prevents shorting between the copper circuit and the metal base. |

| Solder Voiding | < 20% under thermal pad | Ensures heat can actually transfer to the substrate. |

| Peel Strength | > 1.4 N/mm | Prevents traces from lifting under thermal cycling stress. |

The Future: Where This Is Going (Materials, Integration, Ai/automation)

The beacon light industry is moving toward smarter, more integrated solutions. We are seeing a shift from simple "dumb" lights to intelligent nodes that communicate status.

Materials are evolving too. As LEDs become more power-dense, standard aluminum substrates are being pushed to their limits, driving the adoption of nano-ceramic coatings and hybrid materials. APTPCB observes a trend toward integrating control logic directly onto the LED board, reducing the need for separate controller units.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Thermal Conductivity | 1.0 - 2.0 W/mK | 5.0 - 8.0 W/mK | Allows for smaller boards with brighter, hotter LEDs. |

| Integration Level | Discrete Drivers | SoC / Smart Drivers | Enables programmable flash patterns and health monitoring. |

| Form Factor | Rigid Flat Boards | 3D Molded / Flex | Permits aerodynamic designs and seamless vehicle integration. |

Request a Quote / DFM Review for Beacon Light PCB (What to Send)

When you are ready to move from prototype to production, clear communication of your requirements is key. Providing a complete data package helps manufacturers identify potential thermal or assembly risks early.

- Gerber Files: Include all copper layers, soldermask, and silkscreen.

- Material Spec: Explicitly state if you need Aluminum or FR4, and the required thermal conductivity (e.g., 2W/mK).

- LED Datasheets: Providing the specific LED part number helps the factory understand the thermal footprint and soldering profile.

- Copper Weight: Specify if 1oz is sufficient or if 2oz+ is needed for current handling.

- Solder Mask Color: White is often preferred for reflectivity in lighting applications.

- Quantity & Lead Time: Be clear about your ramp-up schedule (e.g., 50 prototypes now, 5k production later).

- Testing Requirements: Do you need Functional Testing (FCT) or specific voltage breakdown tests?

Conclusion

Beacon Light PCBs represent a critical intersection of thermal engineering, power electronics, and mechanical durability. Whether for a police cruiser, an ambulance, or a factory floor, the reliability of the PCB directly impacts safety. Success lies in selecting the right substrate, managing heat effectively, and ensuring rigorous quality control during assembly.

As lighting technology advances, the demands on these boards will only increase. By understanding the trade-offs between material cost and thermal performance, you can design beacons that are both brilliant and enduring. For expert guidance on your next lighting project, contact APTPCB to review your design for manufacturability and performance.