Bidirectional DC-DC converters enable power flow in both directions supporting battery charging from external sources and discharging to loads or grids, requiring sophisticated four-quadrant control maintaining high efficiency (>95%) across charge and discharge modes while providing seamless mode transitions within milliseconds. These converters serve electric vehicles (400-800V traction batteries), stationary energy storage (residential through utility-scale), uninterruptible power supplies, and regenerative industrial drives requiring reliable bidirectional power management through thousands of charge-discharge cycles over 10-15 year operational lifetimes.

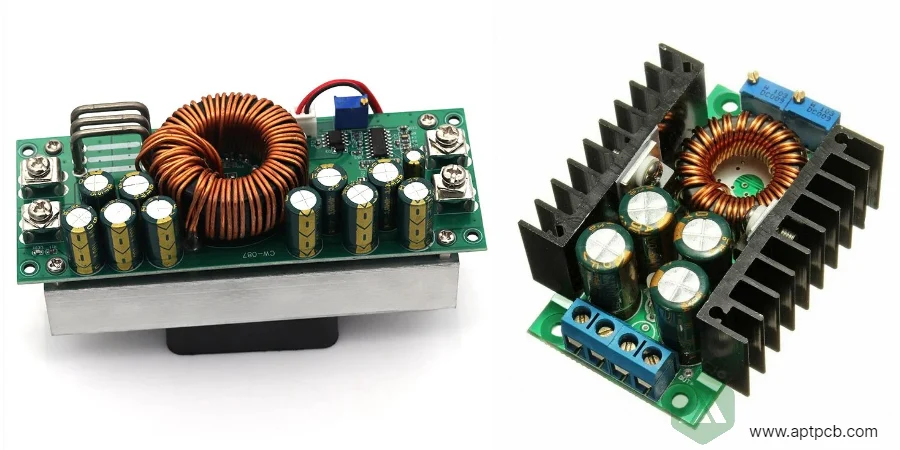

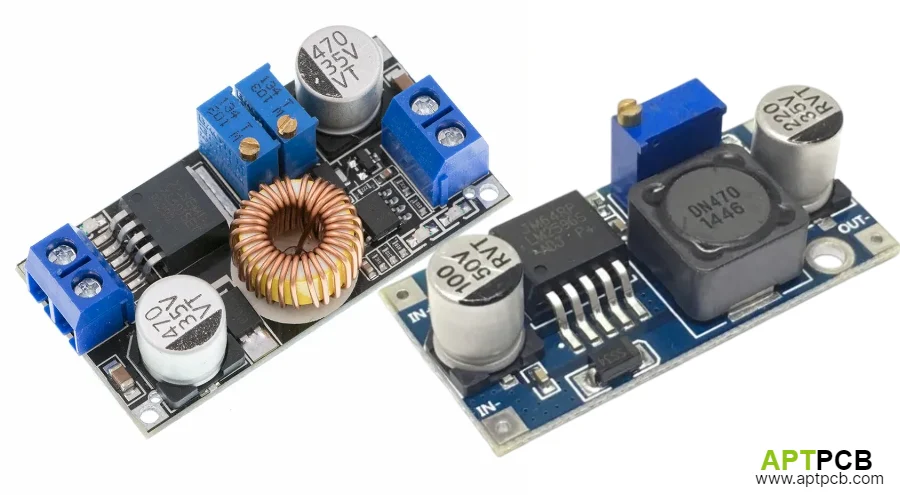

At APTPCB, we manufacture bidirectional converter PCBs with multilayer PCB expertise implementing symmetrical power stages, advanced control architectures, and comprehensive protection circuits. Our capabilities support power ranges from 1kW (residential storage) through 500kW+ (grid-scale ESS and EV fast charging) with validated manufacturing processes ensuring reliable bidirectional operation.

Implementing Four-Quadrant Power Flow

Bidirectional converters must efficiently transfer power in both directions requiring symmetrical power stage designs, bidirectional current sensing, and control algorithms managing smooth transitions between charging and discharging modes. Unlike unidirectional converters optimized for single power flow direction, bidirectional designs balance competing requirements ensuring high efficiency and reliable operation in both quadrants while maintaining compact size and competitive costs.

At APTPCB, our PCB manufacturing implements optimized layouts supporting bidirectional power flow with minimal compromises.

Key Bidirectional Design Requirements

Symmetrical Power Stage Architecture

- Four-quadrant H-bridge or full-bridge topologies using bidirectional switches (MOSFETs with antiparallel diodes or synchronous rectification) enabling current flow in either direction with heavy copper PCB construction handling high currents

- Matched component selection ensuring equivalent forward and reverse voltage drops, switching losses, and thermal characteristics preventing efficiency imbalance between charge and discharge modes

- Synchronous rectification in both directions eliminating diode forward voltage drops improving efficiency by 2-4% compared to passive rectification particularly important at low voltages

- Interleaved multi-phase designs distributing power across parallel stages reducing current stress per device, improving thermal distribution, and enabling higher aggregate power levels

- Isolated or non-isolated configurations depending on safety requirements and voltage matching between battery and load/grid sides

- Modular power stage design enabling scalability to higher power levels through parallel converter stacking maintaining consistent control complexity

Advanced Control Implementation

- Digital control using DSP, FPGA, or microcontrollers executing bidirectional control algorithms at >100kHz update rates maintaining stability across operating modes

- Seamless mode transition logic managing changeover between charge and discharge preventing current discontinuities, voltage overshoots, or protection false trips

- Current mode control with averaged or peak current sensing providing fast dynamic response and inherent overcurrent limiting in both directions

- Voltage mode control maintaining stable DC bus voltage despite bidirectional power flow variations and load/source impedance changes

- Power management algorithms optimizing efficiency across load ranges through adaptive dead-time control, switching frequency modulation, and loss minimization strategies

- Battery management interface coordinating with BMS systems respecting charge voltage limits, discharge cutoff voltages, and current limits ensuring safe battery operation

Bidirectional Current Sensing

- Hall effect sensors measuring DC, AC, or pulsating currents in both directions without polarity concerns providing galvanic isolation

- Bidirectional shunt resistors with differential amplifiers handling positive and negative currents with equal accuracy and bandwidth

- Current transformer sensing for AC current components in resonant or AC-coupled stages providing isolation and wide dynamic range

- High-side and low-side sensing options optimizing for common-mode voltage ranges, isolation requirements, and accuracy specifications

- Proper sensing location minimizing parasitic inductance effects and ensuring measurement represents actual battery or load current

- High-Tg PCB materials maintaining signal integrity and measurement accuracy across temperature ranges

Magnetic Component Design

- Bidirectional transformer or coupled inductor designs accommodating current flow in both directions without saturation or excessive losses

- Flux balancing techniques preventing core bias accumulation which could cause saturation in one direction despite balanced average current

- Winding arrangements minimizing leakage inductance critical for soft-switching operation and voltage spike reduction

- Core material selection (ferrite, powder cores) balancing frequency response, saturation characteristics, and temperature stability

- Thermal management through potting, heat sinks, or forced cooling maintaining core temperatures within specifications during continuous bidirectional power transfer

- Custom magnetics design and validation ensuring performance across full operating envelope including transient conditions during mode transitions

PCB Layout Optimization

- Symmetrical power stage layout ensuring balanced parasitic inductance and thermal distribution in forward and reverse power flow paths

- Ground plane management preventing current loops and ground bounce affecting control signals or measurement accuracy

- Gate drive circuit placement minimizing inductance in gate loops enabling fast, controlled switching in both power flow directions

- Flex PCB or rigid-flex PCB integration enabling three-dimensional layouts optimizing power stage density and thermal management in compact enclosures

- Component placement separating high-frequency switching sections from sensitive analog sensing and control circuits

- Thermal via arrays and copper pours spreading heat from power semiconductors to heat sinks or ambient air

Validated Bidirectional Performance

Through symmetrical power stage design, advanced control implementation, and precision PCB manufacturing supported by our power energy industry expertise, APTPCB delivers bidirectional converter PCBs achieving high efficiency and reliable operation across diverse energy storage and electric vehicle applications.

Optimizing for Battery Charging and Discharging

Battery interface converters require specific optimizations accommodating battery characteristics including voltage ranges varying with state-of-charge (SOC), current limits depending on temperature and age, and charging profiles following multi-stage algorithms (constant-current, constant-voltage, taper charging). Proper battery interface design maximizes battery lifetime, ensures safety during fault conditions, and optimizes energy transfer efficiency reducing losses and heat generation.

APTPCB implements battery-optimized converter designs ensuring safe, efficient energy storage operation.

Key Battery Interface Features

Voltage Range Accommodation

- Wide input/output voltage range (±20-40% around nominal) accommodating battery voltage variation from fully discharged to fully charged states

- Soft-start and pre-charge circuits limiting inrush currents when connecting discharged capacitor banks preventing contact arcing or voltage sag

- Overvoltage and undervoltage protection preventing battery damage from charger malfunctions or excessive discharge despite control system failures

- Voltage balancing in multi-battery systems ensuring even SOC distribution preventing premature capacity loss from imbalanced charging

- Precision voltage regulation (<±0.5%) maintaining charging voltage accuracy critical for lithium-ion batteries where overcharge causes safety risks

- Dynamic voltage adjustment responding to BMS commands accommodating temperature-compensated charging or cell balancing requirements

Current Control and Limiting

- Programmable charge and discharge current limits configurable based on battery specifications, temperature, and aging characteristics

- Accurate current regulation (±1-2%) ensuring battery manufacturers' specifications met preventing warranty violations or safety incidents

- Current slew rate limiting controlling di/dt during mode transitions preventing mechanical stress on battery connections or internal current distribution

- Peak current capability handling brief overloads during motor acceleration or regenerative braking in automotive applications

- Temperature-dependent current derating reducing charge/discharge rates at temperature extremes protecting battery health and safety

- Communication interface with BMS systems receiving real-time current limit updates based on battery state, temperature, and estimated impedance

Multi-Stage Charging Implementation

- Constant-current (CC) charging phase regulating current while battery voltage rises delivering maximum power safely

- Constant-voltage (CV) charging phase regulating voltage as current tapers approaching full charge preventing overcharge

- Taper termination detecting end-of-charge conditions (current drop to 2-5% rated) or timeout preventing excessive overcharge

- Equalization or balancing modes supporting periodic high-voltage charging correcting cell imbalances in series battery strings

- Fast charging algorithms supporting DC fast charging (DCFC) at 1-3C rates with proper thermal management and battery monitoring

- Battery chemistry adaptation supporting diverse chemistries (lithium-ion, LiFePO4, lead-acid) with appropriate voltage and current profiles

Protection and Safety Features

- Battery isolation contactors or solid-state switches disconnecting battery during faults, maintenance, or emergency conditions

- Ground fault detection identifying insulation failures in high-voltage battery systems preventing shock hazards

- Arc flash detection protecting against internal battery shorts or connection failures potentially causing fires

- Thermal runaway detection monitoring rapid temperature rise rates triggering emergency shutdown and external alarms

- Redundant protection layers combining hardware and software safeguards ensuring safe operation despite single-point failures

- Automotive electronics grade components and processes meeting functional safety requirements (ISO 26262) for automotive applications

Managing Mode Transition Control

Smooth transitions between charging and discharging modes prevent current discontinuities causing voltage spikes, electromagnetic interference, or protection circuit false trips. Transition management becomes particularly critical in regenerative applications (electric vehicles, elevators, cranes) where power flow direction changes rapidly based on acceleration or deceleration commands requiring seamless handoff without perceivable delays or torque disturbances.

APTPCB manufactures converters with validated transition control ensuring reliable mode switching.

Key Transition Management Techniques

Zero-Current Switching Strategies

- Current reduction to near-zero before switching power flow direction minimizing switching losses and voltage transients

- Gradual current reversal through controlled ramp rates preventing mechanical shock on battery connections or downstream equipment

- Dead-time insertion during mode transitions ensuring both directions not active simultaneously preventing shoot-through or short circuits

- State machine implementation managing transition sequences, interlocks, and timing ensuring deterministic behavior under all conditions

- Fault detection during transitions identifying abnormal conditions (excessive voltage swing, current overshoot, timing violations) triggering protective shutdown

- Validation testing across thousands of transition cycles at various load levels and battery SOC conditions ensuring reliable switching

Voltage Regulation During Transitions

- Output capacitor sizing providing energy buffering during brief transition periods maintaining load voltage within specifications

- Active voltage control maintaining regulation despite changing input/output roles preventing voltage dips or spikes

- Pre-bias detection verifying voltage matching before closing switches preventing inrush currents during connection

- Load current feedforward adjusting control signals based on predicted load changes improving transient response

- Adaptive control gain scheduling optimizing response across different operating points and power flow directions

- Comprehensive testing validating voltage regulation during transitions across full load range and battery voltage variations

Communication and Coordination

- High-speed communication with battery management systems (CAN bus, SPI) exchanging status, limits, and commands within milliseconds

- Vehicle control unit (VCU) integration receiving torque commands, state-of-charge information, and coordinating regenerative braking

- Grid-tie synchronization in storage applications coordinating with inverters managing power flow direction based on grid demand or solar production

- Redundant communication paths and timeout detection ensuring safe operation despite communication failures

- State broadcasting enabling external systems (displays, diagnostic tools, SCADA) monitoring converter status and power flow

- Support services including protocol development and integration testing ensuring reliable system-level communication

Ensuring Bidirectional Current Sensing

Accurate current measurement in both directions enables closed-loop control, state-of-charge estimation, efficiency monitoring, and protection functions requiring sensors and signal conditioning handling positive and negative currents with equal performance. Sensing errors cause control instability, incorrect SOC calculations, or delayed protection response compromising system performance and safety.

APTPCB implements validated current sensing solutions ensuring measurement accuracy across bidirectional operation.

Key Current Sensing Requirements

Hall Effect Sensor Integration

- Closed-loop Hall effect sensors providing galvanic isolation, bidirectional capability, and wide bandwidth (DC to >100kHz)

- Zero-drift performance through temperature-compensated designs maintaining accuracy across automotive and industrial temperature ranges

- Proper sensor mounting maintaining mechanical stability and minimizing external magnetic field interference

- Calibration procedures accounting for sensor offset, gain errors, and temperature coefficients improving absolute accuracy

- PCB layout minimizing current loop areas and maintaining symmetry ensuring Hall sensor measures intended current path

- Final quality inspection validating sensor installation and calibration before shipment

Differential Amplifier Signal Conditioning

- High common-mode rejection ratio (CMRR >80dB) preventing ground potential differences from affecting measurement accuracy

- Bidirectional input range supporting positive and negative voltages with equal linearity and accuracy

- Bandwidth optimization balancing fast response for control loops against noise filtering preventing measurement errors from switching transients

- Offset and gain calibration compensating for component tolerances and temperature drift maintaining specified accuracy

- Isolation amplifiers when required providing galvanic barrier between high-voltage power stage and low-voltage control electronics

- Incoming quality control screening precision resistors and amplifiers ensuring component quality

Providing Comprehensive Protection

Bidirectional converters require protection against faults in both power flow directions including overcurrent during charge or discharge, overvoltage from battery or source, short circuits on either side, and thermal overload from sustained high-power operation. Protection systems must respond within microseconds to fast-developing faults preventing semiconductor destruction while avoiding false trips during normal transient conditions.

APTPCB implements multi-layer protection ensuring safe operation across all scenarios.

Key Protection Implementation

Bidirectional Overcurrent Protection

- Separate charge and discharge current limits accommodating different battery capabilities in each direction

- Fast overcurrent detection (<10μs) during short circuit conditions immediately opening circuit preventing semiconductor or battery damage

- Slower time-averaged overcurrent protection handling sustained overload conditions implementing thermal protection and derating

- Current-dependent response times coordinating with upstream/downstream protection devices achieving proper selectivity

- Hardware backup protection using comparators or dedicated ICs providing redundancy if primary microcontroller-based protection fails

- Comprehensive testing validating protection activation thresholds, response times, and recovery behavior across production units

Voltage Protection

- Overvoltage protection monitoring both input and output preventing damage from battery overcharge, grid transients, or control failures

- Undervoltage protection detecting battery over-discharge or loss of input power triggering graceful shutdown

- Clamping circuits limiting voltage spikes from switching transients or inductive kickback protecting semiconductors

- Isolated voltage sensing maintaining safety barriers while enabling accurate monitoring of both battery and load/grid voltages

- Protection threshold programming accommodating different battery chemistries and system voltage configurations

- Coordination with external protection devices (contactors, fuses, circuit breakers) ensuring proper fault isolation

Enabling EV and ESS Applications

Electric vehicles and energy storage systems represent primary applications for bidirectional DC-DC converters requiring specific optimizations for automotive functional safety, grid interconnection standards, and high-volume production. Application-specific requirements influence component selection, testing protocols, and certification strategies necessitating flexible manufacturing accommodating diverse specifications.

APTPCB supports EV and ESS manufacturers with application-optimized manufacturing and comprehensive certification support.

Key Application Support

Electric Vehicle Integration

- Automotive-grade components (AEC-Q100/200 qualified) withstanding extended temperature ranges, vibration, and harsh environments

- Functional safety implementation (ISO 26262 ASIL-C/D) ensuring safe operation despite single-point failures

- Onboard charging integration coordinating with AC charging systems managing power flow from grid to battery

- DC fast charging support enabling 50-350kW charging rates with proper thermal management and battery protection

- Vehicle-to-grid (V2G) capability discharging battery to grid during peak demand supporting grid stability and revenue generation

- Compact packaging fitting within vehicle space constraints while maintaining thermal performance and serviceability

Energy Storage Applications

- Grid interconnection compliance meeting IEEE 1547, UL 1741, or regional standards for distributed energy resources

- Wide power scaling from 5kW residential systems through 1MW+ commercial and utility installations

- Multiple battery chemistry support (lithium-ion, LFP, flow batteries) with configurable voltage ranges and charging profiles

- Modular architecture enabling redundancy (N+1 configurations) ensuring high availability in mission-critical applications

- Remote monitoring and control via Modbus, Ethernet, or proprietary protocols integrating into energy management systems

- 20+ year design life matching PV system warranties through robust component selection and derating strategies

Through application-specific optimizations, flexible manufacturing processes, and comprehensive support services, APTPCB enables manufacturers deploying reliable bidirectional converters across rapidly growing electric vehicle and energy storage markets worldwide.