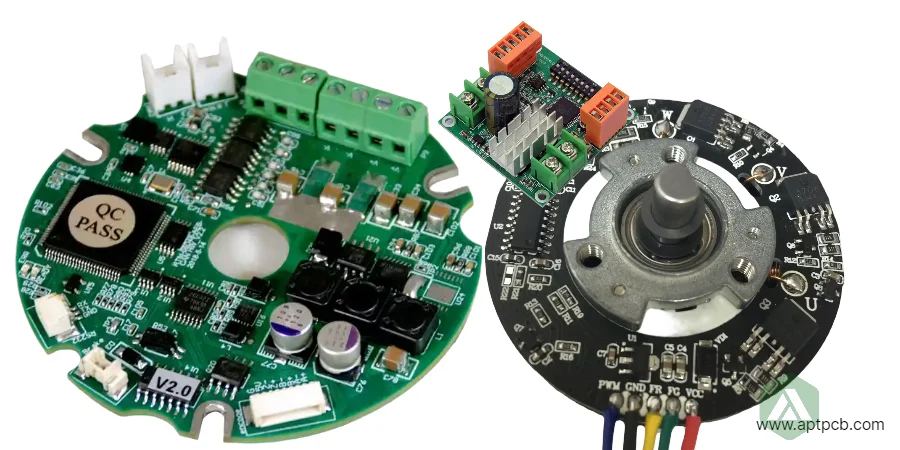

BLDC motor driver assemblies implement sophisticated control algorithms including six-step commutation, sinusoidal field-oriented control (FOC), and sensorless operation using back-EMF detection achieving high efficiency (>95%), smooth torque delivery, and precise speed regulation across drones (quadcopters, fixed-wing), power tools (drills, saws, grinders), appliances (fans, pumps, compressors), and industrial automation requiring reliable brushless motor operation handling 1-100A+ currents through millions of start-stop cycles.

At APTPCB, we deliver specialized BLDC driver assembly services implementing advanced control algorithms, high-current power stages, and comprehensive protection features with aerospace defense quality standards. Our capabilities support 12V through 800V BLDC applications across power ranges from 50W consumer through 50kW+ industrial drives with validated sensorless and FOC algorithm implementation.

Implementing Field-Oriented Control FOC

Field-oriented control transforms three-phase currents into rotating reference frame enabling independent control of torque-producing and magnetizing current components achieving superior performance compared to six-step commutation: smooth torque across speed range, reduced acoustic noise, higher efficiency, and precise torque control. FOC requires high-performance microcontrollers executing complex mathematical transformations (Clarke, Park, inverse Park) at 10-50kHz control loop rates.

At APTPCB, our assembly services support FOC-capable motor drivers with validated control implementations.

Key FOC Implementation Requirements

Control Algorithm Execution

- ARM Cortex-M4/M7 MCUs with DSP and floating-point capability executing FOC algorithms with medical devices reliability for critical applications

- Space vector modulation (SVM) generating optimal PWM patterns maximizing DC bus utilization

- PI current control loops regulating Id and Iq currents achieving desired torque

- Position/speed estimation using phase-locked loops or sliding-mode observers

- Coordinate transformations (Clarke, Park) converting between reference frames

- High-resolution PWM (>200MHz timer) achieving precise voltage vector synthesis

Current Measurement and Sensing

- Three-phase current sensing using shunt resistors or Hall effect sensors

- High-speed ADC sampling (1-2MSPS) capturing instantaneous phase currents

- Synchronous sampling aligned with PWM for accurate current reconstruction

- Amplifier and filtering optimizing signal-to-noise ratio in noisy motor environment

- Over-current detection protecting power stage during fault conditions

- Calibration and offset compensation maintaining accuracy across temperature

Executing Sensorless Control Algorithms

Sensorless BLDC control eliminates Hall sensors or encoders reducing cost, improving reliability, and enabling motor operation in harsh environments. Back-EMF sensing detects zero-crossing points determining rotor position enabling proper commutation timing. Sensorless operation requires sophisticated startup algorithms transitioning from open-loop acceleration through back-EMF detection threshold into closed-loop sensorless control.

APTPCB manufactures sensorless BLDC drivers with validated algorithm implementations.

Key Sensorless Implementation

Back-EMF Detection Methods

- Zero-crossing detection monitoring undriven phase voltage relative to neutral point

- Comparator and filtering extracting zero-crossing events from noisy signals

- Commutation timing adjustment optimizing efficiency across speed and load

- Bemf amplitude monitoring validating rotor position accuracy and detecting faults

- Hardware and software filtering preventing false triggers from switching noise

- Adaptive algorithms compensating for motor parameter variations and temperature

Startup and Transition Control

- Open-loop startup using I-f control ramping frequency with constant current

- Alignment phase establishing known rotor position before rotation

- Acceleration profile gradually increasing speed until back-EMF detectable

- Smooth transition from open-loop to closed-loop avoiding torque discontinuities

- Catch and spin algorithms detecting and synchronizing to already-rotating motors

- Stall detection and recovery restarting motor if synchronization lost

Optimizing for High-Performance Applications

High-performance BLDC applications including racing drones, power tools, and servo drives demand maximum power density, fast dynamic response, and efficient operation requiring optimized power stage design, advanced control algorithms, and comprehensive thermal management achieving continuous operation at rated power without derating.

APTPCB implements high-performance BLDC drivers supporting demanding applications.

High-Performance Features

Power Stage Optimization

- Low Rds(on) MOSFETs minimizing conduction losses at high currents

- Fast switching (10-50kHz) reducing torque ripple and acoustic noise

- Parallel device configurations distributing high currents reducing thermal stress

- Dead-time optimization minimizing body diode conduction losses

- Synchronous rectification during regeneration recovering energy during deceleration

- Thermal management maintaining safe junction temperatures during peak power

Dynamic Response Enhancement

- High-bandwidth current control loops (>5kHz) achieving fast torque response

- Feed-forward control compensating for predictable load changes

- Anti-windup techniques preventing integrator saturation during transients

- Voltage compensation adjusting control based on battery voltage variations

- Adaptive algorithms learning motor characteristics optimizing performance

- Telemetry and tuning interfaces enabling field optimization and diagnostics

Providing Protection and Safety Features

BLDC drivers require comprehensive protection preventing motor and driver damage from overcurrent (stalled rotor, overload), overvoltage (regenerative overvoltage), undervoltage (battery depletion), overtemperature (insufficient cooling), and motor faults (open phase, short circuit). Protection must respond quickly while avoiding false trips during normal operation.

APTPCB implements multi-layer BLDC protection ensuring safe operation.

Protection Implementation

Overcurrent and Stall Protection

- Hardware overcurrent shutdown responding within microseconds

- Software current limiting reducing power during sustained overload

- Stall detection identifying blocked rotor triggering shutdown

- I²t thermal model preventing thermal damage from transient overcurrents

- Phase current monitoring detecting open or shorted motor phases

- Diagnostic codes identifying specific fault conditions supporting troubleshooting

Battery and Thermal Management

- Under-voltage cutoff protecting LiPo batteries from over-discharge damage

- Over-voltage protection during regenerative braking preventing bus overvoltage

- Active brake resistor control dissipating regenerative energy when necessary

- Temperature monitoring and derating reducing power at elevated temperatures

- Thermal shutdown preventing component damage from overheating

- Battery cell monitoring coordinating with BMS systems in equipped applications

Supporting Diverse BLDC Applications

BLDC drivers serve applications including drones and UAVs (multirotors, fixed-wing), power tools (cordless drills, impact drivers), consumer appliances (fans, pumps, vacuum cleaners), and e-mobility (e-bikes, e-scooters, electric skateboards) requiring application-specific optimizations in control algorithms, interfaces, power levels, and environmental specifications.

APTPCB provides flexible BLDC manufacturing supporting diverse applications.

Application-Specific Optimization

Drone and UAV Applications

- Ultra-light weight minimizing payload impact maximizing flight time

- High power density (>100W/cm³) enabling compact ESC integration

- Fast throttle response (<10ms) supporting aggressive flight maneuvers

- Smooth torque minimizing vibration affecting flight control and camera

- Telemetry interfaces (PWM, DShot, UART) communicating with flight controllers

- Waterproof conformal coating surviving outdoor operation in weather

Power Tools and Appliances

- Cost optimization meeting competitive consumer electronics pricing

- Battery compatibility supporting various cell chemistries (Li-ion, NiMH, NiCd)

- Soft-start reducing mechanical stress on gearbox and motor

- Electronic brake quickly stopping motor for safety and convenience

- Thermal management surviving sustained high-power operation

- Regulatory compliance (CE, FCC, UL) enabling global market access

Through application-optimized designs, flexible manufacturing, and comprehensive testing coordinated with server data center quality standards, APTPCB enables BLDC driver manufacturers serving diverse consumer, industrial, and specialty markets worldwide.

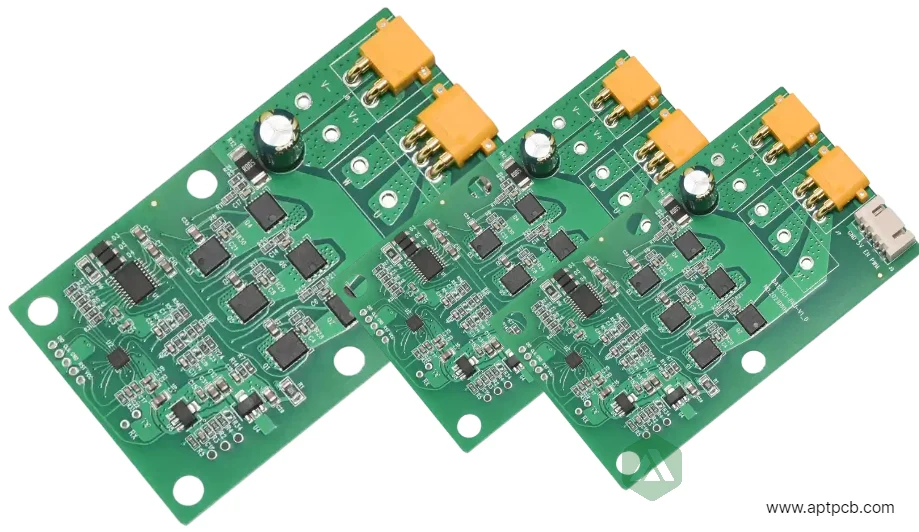

Enabling Volume Manufacturing

BLDC driver production for consumer electronics and drones requires high-volume manufacturing capability achieving competitive costs while maintaining performance and reliability. Manufacturing optimization through automation, testing efficiency, and supply chain management enables volume production supporting successful mass-market products.

APTPCB delivers high-volume BLDC driver manufacturing.

Volume Production Excellence

Manufacturing Capabilities

- Automated assembly handling fine-pitch components and precise placement

- Motor load testing validating driver performance with actual BLDC motors

- Functional testing verifying control algorithms, protection, and interfaces

- Environmental testing confirming operation across temperature and humidity ranges

- Statistical process control monitoring quality enabling continuous improvement

- Global manufacturing footprint supporting regional customer requirements

Through high-volume manufacturing capabilities, comprehensive testing, and quality management coordinated with security equipment standards, APTPCB enables BLDC driver manufacturers deploying cost-effective, high-performance brushless motor control solutions in competitive global markets.