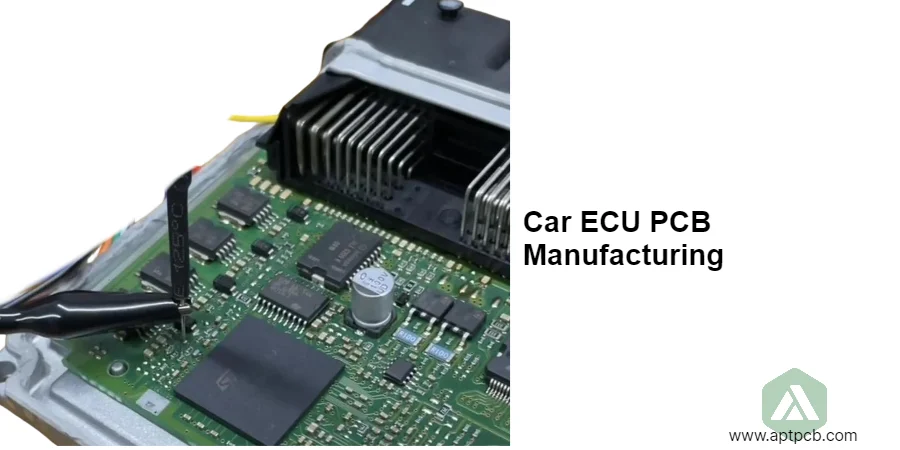

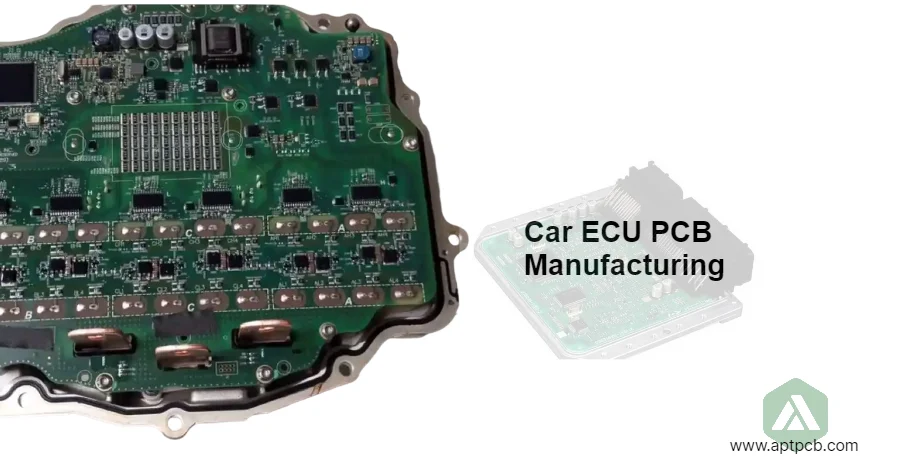

Automotive ECU PCB manufacturing supports engine control, transmission control, body electronics, and vehicle systems requiring AEC-Q qualified components, extended temperature operation (-40 to +125°C), robust EMC performance, and 15+ year reliability across powertrain management, transmission control, body control modules, and specialized vehicle functions demanding precise sensor processing, actuator control, and CAN network communication supporting millions of operating hours through vehicle lifecycles.

At APTPCB, we manufacture automotive ECU PCBs with automotive electronics expertise implementing qualified processes and comprehensive testing supporting diverse ECU applications.

Implementing Robust Powertrain Control

Engine and transmission ECUs execute real-time control algorithms managing fuel injection, ignition timing, valve timing, and transmission shifting requiring high-speed ADCs sampling sensors at 1-10kHz, precise PWM output controlling actuators, and deterministic execution meeting <1ms control loop timing. Powertrain control challenges include maintaining calibration accuracy across temperature variations, achieving emissions compliance through precise fuel control, and providing fail-safe operation during sensor or actuator failures. Inadequate control implementation causes poor engine performance, increased emissions failing regulations, or drivability issues affecting customer satisfaction — significantly impacting vehicle compliance, fuel economy, and driving experience.

At APTPCB, our manufacturing supports precision powertrain control achieving emissions compliance and optimal performance.

Powertrain Control Implementation

- Automotive Microcontrollers: Multi-core MCUs (Infineon AURIX, NXP MPC5xxx, Renesas RH850) with real-time capabilities and quality system qualification.

- High-Resolution ADCs: 12-16 bit converters sampling oxygen sensors, temperature, pressure, and position sensors at kHz rates enabling precise control.

- Precision PWM Outputs: High-frequency PWM (10-100kHz) controlling fuel injectors, ignition coils, and variable valve timing with microsecond timing accuracy.

- Robust Sensor Interfaces: Pull-ups, filtering, and protection circuits handling diverse sensor types across automotive electrical environment.

- Actuator Drivers: High-side/low-side drivers with current limiting and diagnostic feedback controlling solenoids, motors, and heaters.

Ensuring EMC Compliance and Electrical Robustness

ECUs operate in electrically harsh automotive environments with ignition transients, alternator ripple, and EMI from surrounding electronics requiring comprehensive EMC design achieving conducted and radiated emissions limits while surviving electrical transients per ISO 7637. EMC challenges include filtering high-frequency noise, protecting against load dump (100V transients), and preventing radiated emissions affecting radio reception. Inadequate EMC implementation causes AM radio interference, ECU resets from transients, or component damage from electrical events — significantly impacting vehicle electrical reliability and regulatory compliance.

At APTPCB, our manufacturing implements automotive EMC strategies achieving regulatory compliance and electrical robustness.

EMC Implementation

- Transient Protection: TVS diodes and suppression networks protecting against load dump, inductive kickback, and ESD events per testing quality standards.

- Input Filtering: Pi-filters and ferrite beads attenuating conducted emissions and susceptibility on power and CAN lines.

- PCB Layout Optimization: Ground plane integrity, signal trace routing, and via stitching minimizing loop areas reducing radiated emissions.

- Shielded Enclosures: Grounded metal housings with gaskets and filtered connectors containing emissions and improving immunity.

Managing Thermal Performance in Underhood Environments

Powertrain ECUs mounted near engines experience -40 to +125°C operating temperatures requiring robust thermal management, temperature-qualified components, and validated thermal design. Thermal challenges include dissipating heat from power drivers and regulators, maintaining electronic performance at temperature extremes, and preventing thermal runaway. Inadequate thermal design causes premature component failure, intermittent operation at temperature extremes, or thermal shutdown during normal operation — significantly impacting reliability and warranty costs.

At APTPCB, our manufacturing implements thermal strategies ensuring reliable underhood operation.

Thermal Management

- Heavy Copper Construction: 2-4oz copper distributing heat from power components across PCB area with NPI assembly validation.

- Thermal Interface to Housing: Precision gap control between power devices and metal enclosure enabling heat extraction to vehicle structure.

- High-Temperature Components: AEC-Q200 parts rated to 150-175°C junction temperatures surviving underhood conditions.

- Thermal Simulation: CFD analysis predicting component temperatures validating thermal design before production.

Supporting CAN Network Communication

Modern vehicles use CAN, CAN-FD, LIN, and FlexRay networks connecting 50-100+ ECUs requiring robust network interfaces, protocol implementation, and diagnostic capabilities. Network challenges include achieving bus loading requirements, implementing error handling and recovery, and providing diagnostic access. Inadequate network implementation causes communication errors affecting vehicle operation, slow diagnostic response complicating service, or EMC susceptibility disrupting networks — significantly impacting vehicle electrical reliability and serviceability.

At APTPCB, our manufacturing supports automotive network integration achieving reliable vehicle communication.

Network Implementation

- CAN Transceivers: Automotive-qualified transceivers with fault protection and bus monitoring capabilities.

- Termination and Biasing: Proper network termination maintaining signal integrity across temperature and preventing reflections.

- Protocol Implementation: Validated communication stacks implementing CAN/CAN-FD protocols with diagnostic services.

- Network Diagnostics: OBD-II and UDS diagnostic support enabling vehicle troubleshooting and ECU reprogramming.

Providing Long-Term Automotive Support

ECU production programs span 15+ years requiring component availability, design change control, and field support. Lifecycle challenges include managing component obsolescence, validating design changes, and supporting field failures. Inadequate lifecycle support causes supply interruptions, expensive last-time buys, or inability to repair vehicles — significantly impacting total cost of ownership and customer satisfaction.

At APTPCB, we provide comprehensive ECU lifecycle support throughout vehicle production.

Lifecycle Support

- Long-Term Component Availability: Automotive-grade components with extended lifecycle commitments and mass production scalability.

- Obsolescence Management: Proactive monitoring and alternative qualification before availability issues.

- Change Control: Rigorous PPAP process validating modifications maintaining form, fit, and function.

- Field Failure Analysis: Root cause analysis and corrective action supporting continuous improvement.

Through comprehensive lifecycle support and automotive expertise coordinated with component sourcing management, APTPCB enables successful ECU programs from development through end-of-life.