Contents

- The Context: What Makes Common Mode Choke Layout Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Common Mode Choke Layout (What to Send)

- Conclusion

Highlights

- Parasitic Management: How trace geometry and stackup affect the "invisible capacitor" that ruins high-frequency performance.

- Placement Strategy: Why distance from the connector determines filtering efficiency.

- Thermal & Mechanical: Handling heat dissipation in power chokes and vibration in heavy through-hole components.

- Differential Integrity: Maintaining controlled impedance through the filter for high-speed interfaces like USB and Ethernet.

The Context: What Makes Common Mode Choke Layout Challenging

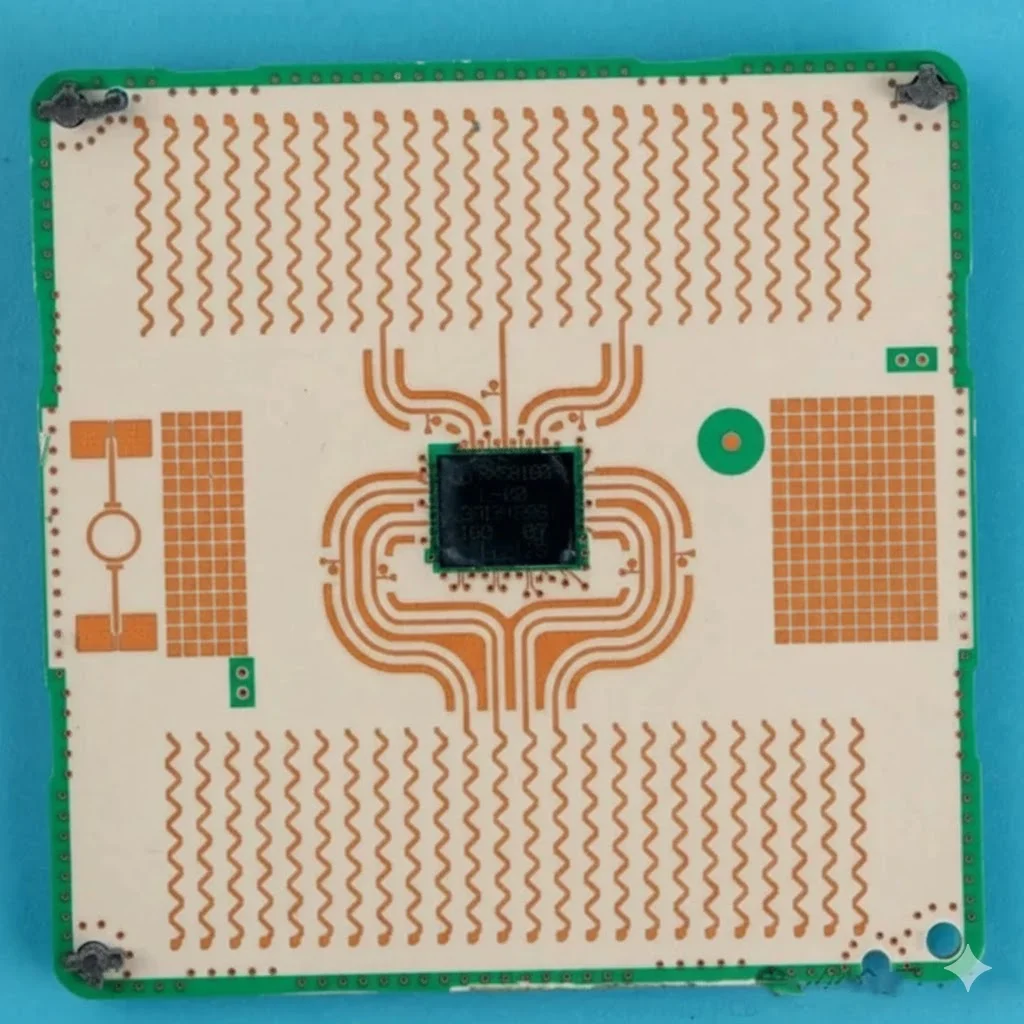

The fundamental challenge in laying out a common mode choke (CMC) is that the component does not exist in a vacuum. On a schematic, a CMC is a perfect inductor pair. On a printed circuit board (PCB), it is a complex 3D structure surrounded by copper that creates parasitic capacitance. If the input and output pads are too close, or if ground planes run beneath the component, high-frequency noise can capacitively couple across the choke, effectively bypassing the magnetic filtering you paid for.

Furthermore, modern electronics demand conflicting requirements: higher power density (requiring larger, hotter chokes) and smaller form factors (forcing components closer together). Engineers must balance the need for wide traces to handle current against the need for separation to prevent noise coupling. This is compounded by manufacturing constraints; heavy chokes can suffer from solder joint fatigue if not properly supported, making the layout a structural concern as well as an electrical one.

The Core Technologies (What Actually Makes It Work)

Successful common mode choke layout relies on mastering a few core physical mechanisms. It is rarely about just dropping a footprint on the board; it is about shaping the electromagnetic fields around that footprint.

- Parasitic Capacitance Minimization: The primary goal is to reduce the stray capacitance between the "noisy" input side and the "quiet" output side. This is often achieved by removing copper planes (ground and power) from all layers directly underneath the choke body. This "void" prevents the ground plane from acting as a capacitive bridge.

- Controlled Impedance Routing: For data lines (like USB, HDMI, or Ethernet), the traces entering and exiting the choke must maintain a specific differential impedance (usually 90 or 100 ohms). A sudden change in trace width or separation at the choke pads causes reflections, degrading signal integrity. Advanced High Speed PCB fabrication techniques ensure these tolerances are met even around component pads.

- Magnetic Separation: CMCs work by magnetic coupling. If they are placed too close to other magnetic components (like transformers or other inductors), their fields can interact, leading to crosstalk or saturation. Proper spacing and orientation (sometimes rotating adjacent chokes by 90 degrees) are critical technologies in the layout phase.

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

The layout of a common mode choke is deeply intertwined with the rest of the system, particularly the mechanical enclosure and the external interfaces.

The Connector Interface The most critical relationship is between the CMC and the I/O connector. The "Golden Rule" of EMC layout is to place the filter as close to the connector as possible. If there is a long trace between the choke and the connector, that trace acts as an antenna, picking up noise from inside the enclosure and radiating it out, or vice versa.

Grounding Architecture The chassis ground and signal ground often meet near the I/O area. The CMC layout must respect the isolation between these grounds. In many designs, a "moat" or separation line exists in the ground plane, bridged only by the CMC and specific capacitors. This forces common-mode currents to pass through the choke rather than flowing around it through the ground plane.

Assembly and Handling From a manufacturing perspective, large CMCs (especially for power applications) are heavy. During Box Build Assembly, shock and vibration can crack solder joints. Layouts often need to include extra space for adhesive bonding or use robust through-hole footprints instead of surface mount pads for mechanical stability.

Comparison: Common Options and What You Gain / Lose

Engineers often face trade-offs when integrating CMCs. Should you prioritize thermal performance or noise isolation? Should you use a compact SMD part or a rugged through-hole part? The layout decisions ripple through the product's performance.

One common debate is regarding the ground plane beneath the component. While a solid ground plane provides shielding and heat spreading, it increases parasitic capacitance. Removing it improves filtering but reduces thermal dissipation.

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| Voiding ground under choke | Reduces input-to-output parasitic capacitance; improves high-frequency noise rejection significantly. |

| Placing choke near connector | Maximizes filtering efficiency by preventing noise from bypassing the filter via radiative coupling on long traces. |

| Using thick copper (2oz+) | Lowers DC resistance and heat generation but requires larger clearance gaps, consuming more board space. |

| Symmetric differential routing | Prevents "mode conversion" where differential signals accidentally convert into common-mode noise due to imbalances. |

For high-power applications, the trade-off often leans toward thermal management. In these cases, Heavy Copper PCB technology allows for substantial heat dissipation through the traces themselves, mitigating the need for a ground plane directly under the hot component.

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

Reliability in common mode choke layout is multi-dimensional. It is not just about the part surviving; it is about the signal surviving the part.

Signal Integrity (SI) For high-speed differential pairs, the CMC is a discontinuity. The layout must minimize the "stub" length of the pads. The transition from the trace to the pad should be tapered if possible to reduce impedance mismatch. If the layout is poor, the "eye diagram" of the signal will close, leading to data errors.

Thermal Reliability Power line CMCs can get very hot. The layout must provide adequate copper area on the pads to act as a heatsink. If the layout restricts airflow or lacks thermal mass, the core temperature may exceed the Curie temperature of the ferrite, causing the choke to lose its magnetic properties and stop filtering noise entirely.

Process Control During manufacturing, the orientation of the component matters. For wave soldering, the orientation of a through-hole choke relative to the wave direction affects solder fill. For reflow, the thermal balance of the pads prevents "tombstoning."

| Verification Step | Acceptance Criteria | Why it Matters |

|---|---|---|

| Impedance Check | ±10% of target (e.g., 90Ω) | Ensures data integrity across the filter. |

| High-Pot Test | No breakdown at 1.5kV (typical) | Verifies isolation spacing under the choke. |

| Thermal Scan | < 40°C rise at max current | Prevents core saturation and board damage. |

| Vibration Test | No solder cracks after sweep | Ensures heavy chokes are mechanically stable. |

Proper PCB Stack-up planning is essential here, ensuring that internal layers provide the necessary reference planes for the traces leading up to the choke, without compromising the isolation void under the choke itself.

The Future: Where This Is Going (Materials, Integration, Ai/automation)

As switching frequencies in power electronics rise with the adoption of Gallium Nitride (GaN) and Silicon Carbide (SiC), the demands on common mode chokes are changing. We are moving away from bulky wire-wound toroids toward planar magnetics and integrated solutions that require very different layout strategies.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Operating Frequency | kHz to low MHz | High MHz to GHz | Faster switching speeds (GaN/SiC) generate noise at much higher frequencies. |

| Integration Level | Discrete components | Embedded Planar Coils | Reduces assembly height and improves consistency by printing windings directly on the PCB. |

| Thermal Management | Passive air/copper | Active substrate cooling | High power density requires heat to be pulled directly through the board substrate. |

The shift toward Ceramic PCB materials is also enabling better thermal management for these high-frequency, high-power integrated magnetics, allowing the layout itself to become the cooling solution.

Request a Quote / DFM Review for Common Mode Choke Layout (What to Send)

When requesting a quote or a Design for Manufacturing (DFM) review for a board featuring critical common mode choke layouts, providing specific details helps APTPCB (APTPCB PCB Factory) ensure your EMI performance goals are met.

- Gerber Files: Include all copper layers and drill files.

- Impedance Requirements: Specify if the traces entering the choke are differential pairs (e.g., 90Ω or 100Ω).

- Component Datasheet: Provide the datasheet for the specific CMC to verify pad geometry and thermal needs.

- Current Rating: High-current chokes may require heavier copper weights (2oz, 3oz, etc.).

- Keep-out Areas: Clearly mark areas where ground planes must be voided under the component.

- Stackup Preference: If you have a specific layer stackup for EMI control, include it.

- Testing Requirements: Mention if Hi-Pot testing or specific impedance testing is required on the bare board.

Conclusion

The layout of a common mode choke is a subtle art that balances electrical isolation, signal integrity, and thermal endurance. It transforms a simple component into a robust filter capable of silencing noise and passing compliance tests. Ignoring the layout details—like the ground void or connector proximity—can render even the best filter ineffective.

As designs become more compact and frequencies rise, partnering with a manufacturer who understands these nuances becomes critical. APTPCB combines advanced fabrication capabilities with deep engineering support to ensure your layout translates into a reliable, compliant product. Whether you are filtering a high-speed data line or a kilowatt-class power supply, precise execution in the PCB fab is the final step in securing your design's success.