Controlled impedance represents a fundamental requirement for high frequency printed circuit boards where signal wavelengths become comparable to trace lengths and transmission line effects dominate circuit behavior. Impedance mismatches cause reflections degrading signal integrity, reducing power transfer efficiency, and creating resonances affecting system performance. Achieving and maintaining precise impedance control requires coordinated attention to materials, design, and precision manufacturing processes.

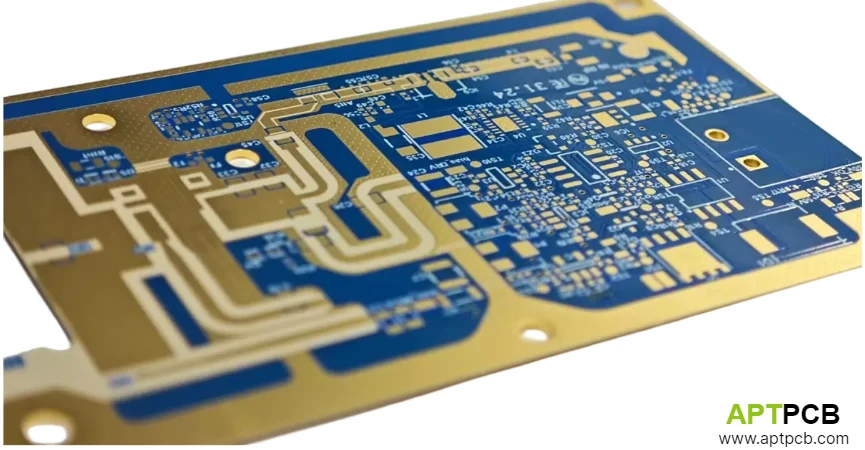

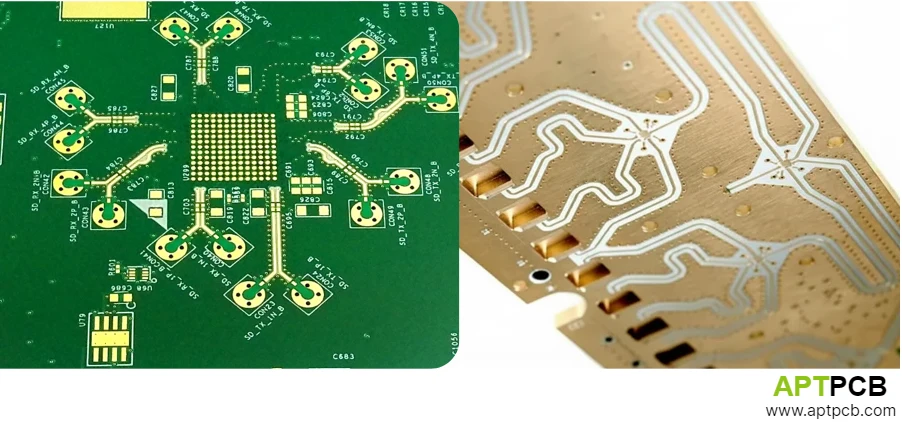

At APTPCB, we manufacture controlled impedance high frequency PCBs with specialized expertise implementing precision fabrication, tight tolerance control, and comprehensive verification. Our capabilities support RF high frequency PCB applications requiring ±5% impedance tolerance with validated manufacturing processes ensuring consistent performance.

Understanding Transmission Line Fundamentals

Characteristic impedance describes the instantaneous relationship between voltage and current on transmission lines, determined by distributed inductance and capacitance per unit length. Understanding impedance fundamentals guides design decisions and manufacturing requirements. Inadequate impedance understanding causes designs not meeting specifications, manufacturing processes not achieving tolerance, or mismatch issues affecting system performance — directly impacting product functionality and reliability.

At APTPCB, our manufacturing implements transmission line theory for precision impedance control.

Key Transmission Line Concepts

- Characteristic Impedance: Z₀ = √(L/C) relating distributed inductance and capacitance per unit length determined by conductor geometry, spacing from reference planes, and dielectric properties.

- Reflection and Matching: Impedance discontinuities causing signal reflections with reflection coefficient quantifying mismatch severity affecting power transfer through high frequency multilayer PCB constructions.

- Standing Waves and VSWR: Voltage standing wave ratio indicating mismatch severity with higher values creating stress points and efficiency reduction.

- Standard Impedance Values: 50Ω for single-ended RF transmission lines and 100Ω differential for high-speed digital representing practical industry standards.

- Frequency-Dependent Effects: Skin effect and dispersion modifying effective impedance at very high frequencies requiring consideration for millimeter-wave designs.

- Temperature Effects: Material property changes with temperature causing impedance variations requiring consideration for wide temperature range applications.

Impedance Fundamentals Application

Through comprehensive understanding of transmission line behavior, appropriate design rules, and precision manufacturing coordinated with impedance requirements, APTPCB enables controlled impedance PCBs meeting demanding specifications.

Managing Factors Affecting Impedance

Multiple fabrication parameters affect achieved impedance including trace width, dielectric thickness, copper thickness, and material properties. Understanding parameter sensitivity guides manufacturing process control priorities. Inadequate parameter management causes impedance variations exceeding tolerance, inconsistent results between production lots, or inability to achieve tight specifications — directly impacting product quality and customer satisfaction.

At APTPCB, our manufacturing controls all factors affecting impedance.

Key Impedance Factors

- Trace Width Effects: Primary design variable with wider traces having lower impedance requiring tight width control through high frequency PCB fabrication precision etching achieving ±0.5 mil tolerance.

- Dielectric Thickness Effects: Thinner dielectric increasing capacitance and reducing impedance with lamination control maintaining consistent thickness.

- Dielectric Constant Effects: Higher dielectric constant reducing impedance with material selection and characterization ensuring accurate design calculations.

- Copper Thickness Effects: Secondary impedance factor through changes to inductance and capacitance distributions controlled through plating uniformity.

- Etch Factor Characterization: Trapezoidal conductor cross-sections from etching requiring compensation with process characterization establishing predictable etch factors.

- Adjacent Trace Coupling: Nearby traces affecting effective impedance requiring minimum spacing rules preventing coupling effects.

Parameter Control Excellence

By controlling all impedance factors through precision processes, material management, and statistical monitoring, APTPCB achieves impedance accuracy meeting demanding tolerance requirements.

Implementing Design Methods for Impedance Control

Controlled impedance design relies on field solver analysis, stackup planning, and design rule implementation translating impedance requirements into manufacturable geometries. Design methods must account for manufacturing tolerances and material variations. Inadequate design methods cause achievable impedance missing targets, tolerance stack-ups exceeding specifications, or designs not manufacturable with available processes — directly impacting development success and time to market.

At APTPCB, our engineering supports impedance-controlled design implementation.

Key Design Capabilities

- Field Solver Analysis: Two-dimensional electromagnetic analysis calculating accurate impedance from specified geometries with parameterized exploration of variations through high frequency PCB manufacturer engineering support.

- Stackup Planning: Layer configuration balancing impedance requirements, routing needs, and manufacturing constraints with target impedances constraining acceptable dielectric thicknesses.

- Differential Pair Design: Edge-coupled or broadside-coupled differential pairs with controlled coupling maintaining differential impedance through consistent spacing.

- Via Transition Optimization: Anti-pad sizing, via diameter, and ground via placement minimizing discontinuities in impedance-controlled paths.

- Tolerance Analysis: Statistical analysis predicting impedance variation from manufacturing tolerances guiding design margins.

- Design Rule Documentation: Clear specification of impedance targets, tolerances, and coupon requirements ensuring manufacturing understanding.

Design Support Excellence

Through field solver capabilities, stackup expertise, and design support coordinated with manufacturing capabilities, APTPCB enables controlled impedance designs achieving targets within tolerance.

Achieving Manufacturing Precision for Impedance

Controlled impedance manufacturing requires tight trace width control, consistent dielectric thickness, and uniform plating achieving specified tolerances. Different tolerance levels require different process capabilities. Inadequate manufacturing precision causes impedance outside specification, excessive variation between boards, or inability to achieve tighter tolerances — directly impacting yield and customer requirements.

At APTPCB, our manufacturing implements precision control for impedance accuracy.

Key Manufacturing Controls

- Precision Trace Width: Direct imaging and controlled etching achieving width tolerances to ±0.5 mil with statistical monitoring tracking dimensional results through RF circuit board manufacturing processes.

- Dielectric Thickness Control: Lamination processes achieving consistent thickness with copper balancing reducing variations from differential prepreg flow.

- Etch Compensation: Artwork dimension adjustment accounting for expected etch factor with compensation tailored to material and copper weight combinations.

- Plating Uniformity: Copper thickness control within ±10% affecting impedance and via reliability with pulse plating improving distribution.

- Process Characterization: Statistical data establishing achievable tolerances for each material and process combination enabling accurate quotation.

- Tolerance Achievement: Standard ±10%, enhanced ±7%, and premium ±5% impedance tolerance capabilities with process controls matched to requirements.

Manufacturing Precision Excellence

By implementing precision processes, statistical control, and continuous improvement supported by process characterization, APTPCB achieves manufacturing accuracy enabling controlled impedance PCBs meeting demanding tolerance specifications.

Verifying Impedance Through Comprehensive Testing

Production impedance verification using test coupons confirms achieved values with statistical analysis supporting process control. Coupon design, measurement procedures, and data analysis determine verification effectiveness. Inadequate verification misses impedance issues, provides inaccurate data for process control, or lacks documentation supporting customer requirements — impacting product quality and customer confidence.

At APTPCB, our testing provides comprehensive impedance verification.

Key Verification Capabilities

- TDR Measurement: Time domain reflectometry measuring characteristic impedance along transmission line test structures with calibrated equipment ensuring accuracy through testing quality protocols.

- Coupon Design: Test structures representing actual product geometries with line widths, spacings, and stackup positions matching controlled impedance traces in designs.

- Multiple Coupon Locations: Coupons positioned across panel area revealing uniformity with statistical analysis of coupon data supporting process control.

- Differential Pair Testing: Odd and even mode impedance measurement for differential pairs confirming both single-ended and differential values.

- Statistical Reporting: Mean, standard deviation, and Cpk data documenting process capability with trend analysis identifying drift requiring attention.

- Correlation Validation: Comparison between coupon measurements and product performance validating test approach with ongoing monitoring.

Verification Excellence

Through comprehensive impedance testing, calibrated equipment, and systematic data analysis coordinated with quality requirements, APTPCB validates controlled impedance PCB performance meeting customer specifications.

Supporting Application-Specific Requirements

Different applications impose varying controlled impedance requirements from digital protocols specifying particular values to RF systems requiring precision matching. Understanding application context guides appropriate tolerance specifications and verification approaches. Inadequate application understanding causes over-specification increasing cost, under-specification risking performance, or inappropriate verification approaches — impacting product suitability and economics.

At APTPCB, our manufacturing supports diverse controlled impedance applications.

Key Application Areas

High-Speed Digital Interfaces

- PCIe, USB, HDMI, and other protocols specifying impedance values and tolerances for reliable signal transmission.

- DDR memory interfaces requiring controlled impedance for signal integrity at high data rates.

- Ethernet and networking interfaces with specified impedance for proper termination matching.

- LVDS and other differential signaling requiring precise differential impedance for high frequency multilayer PCB digital applications.

RF and Microwave Systems

- 50Ω transmission lines standard for RF systems with tight tolerance for matching network performance through microwave RF PCB capabilities.

- Phased array systems requiring consistent impedance across production volumes for array calibration.

- Filter and matching network implementations depending critically on terminating impedances.

- Test equipment requiring precision impedance for accurate measurements.

Mixed-Signal Applications

- Combining digital interfaces with RF circuits on single boards with appropriate impedance control for each section.

- Medical devices requiring reliable signal transmission with controlled impedance paths.

- Industrial equipment with high-speed digital and analog circuits requiring isolation and impedance control.

Application Excellence

Through application understanding, appropriate tolerance specification, and verification aligned with requirements, APTPCB delivers controlled impedance PCBs meeting diverse application needs.

Managing Impedance Discontinuities

Real PCB designs contain impedance discontinuities from via transitions, connector interfaces, and component connections despite best control efforts. Cumulative discontinuity effects impact system performance requiring design strategies and manufacturing precision to minimize impacts. Inadequate discontinuity management causes reflections degrading signal integrity, resonances affecting frequency response, or excessive return loss — directly impacting circuit performance.

At APTPCB, our manufacturing supports discontinuity minimization strategies.

Key Discontinuity Management Capabilities

- Via Transition Optimization: Anti-pad sizing, via diameter, and ground via placement minimizing transition discontinuities through low-loss high frequency PCB design practices.

- Backdrilling: Controlled-depth drilling removing via stubs preventing resonances from unused via barrel portions.

- Connector Launch Design: Precision fabrication of connector interface geometries maintaining impedance continuity.

- Taper Transitions: Gradual impedance transitions between different characteristic impedance sections when required.

- Compensation Structures: Fabrication of compensation geometries offsetting discontinuity reactance.

- Time Domain Analysis: TDR measurement revealing discontinuity locations and magnitudes for optimization validation.

Discontinuity Excellence

By supporting optimized transition designs, precision fabrication, and verification through TDR analysis, APTPCB enables controlled impedance PCBs minimizing discontinuity impacts on system performance.