Contents

- Highlights

- What Is DFM Guidelines for PCB Layout? (Scope & Boundaries)

- Metrics That Matter (How to Evaluate It)

- How to Choose (Material & Design Selection)

- Implementation Checkpoints (from Design to Fab)

- Common Mistakes (and How to Avoid Them)

- Supplier Qualification Checklist: How to Vet Your Fab

- Glossary

- 6 Essential Rules for DFM Guidelines for PCB Layout (Cheat Sheet)

- FAQ

- Request a Quote / DFM Review for DFM Guidelines for PCB Layout

- Conclusion

In the world of electronics hardware, there is often a painful gap between a "perfect" CAD design and a physical board that works reliably. You might have routed every signal with precision and passed every electrical rule check (ERC), yet the board fails on the factory floor due to acid traps, insufficient annular rings, or impossible drill aspect ratios. This is where dfm guidelines for pcb layout (Design for Manufacturing) come into play. DFM is not just a checklist; it is an engineering philosophy that aligns your design intent with the physical realities of chemical etching, mechanical drilling, and lamination.

At APTPCB, we see thousands of designs annually. The difference between a project that launches on time and one that suffers weeks of "engineering questions" (EQs) almost always comes down to how well the designer understood the manufacturing process. This guide serves as your definitive authority on bridging that gap, ensuring your layouts are not just electrically correct, but manufacturable at scale.

Highlights

- The Core Definition: Understanding why DFM is distinct from DRC (Design Rule Check) and why it matters for yield.

- Critical Metrics: How to calculate Aspect Ratio, Annular Ring, and Copper-to-Edge clearance to prevent fabrication failures.

- Material Selection: Balancing electrical performance (Signal Integrity) with mechanical robustness (Tg and CTE).

- The Implementation Roadmap: A 4-step phase guide from initial setup to Gerber generation.

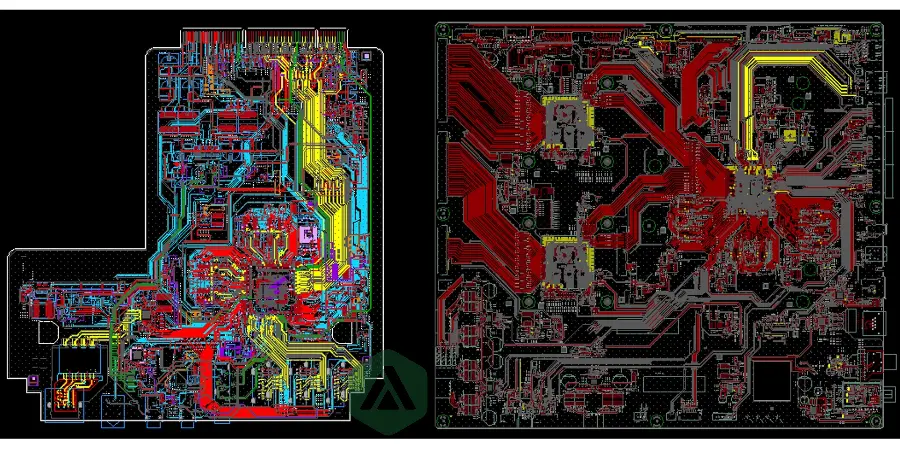

- Defect Prevention: Visual examples of common layout mistakes like slivers and acid traps.

- Supplier Vetting: The exact questions to ask your fabrication house before you start routing.

What Is DFM Guidelines for PCB Layout? (Scope & Boundaries)

dfm guidelines for pcb layout refer to the set of design practices that ensure a Printed Circuit Board can be manufactured cost-effectively and with high yield using current fabrication technologies. While Design Rule Checks (DRC) in your CAD software verify that you haven't shorted a net or left a pin unconnected, DFM verifies that the factory machinery can actually build what you have drawn.

For example, your CAD tool might allow you to place a 4-mil trace 3 mils away from a pad. However, in the physical world, the etching process might over-etch that trace, causing an open circuit, or the solder mask might not adhere to that sliver of space, causing a bridge during assembly. DFM is about managing tolerances.

The scope of DFM covers three main physical constraints:

- Chemical Constraints: Etch factors, plating distribution, and surface finish planarity.

- Mechanical Constraints: Drill wander, registration tolerance, and routing profiles.

- Material Constraints: CTE (Coefficient of Thermal Expansion) mismatch, lamination pressure, and resin flow.

Ignoring these guidelines doesn't just mean higher costs; it often results in "scrap"—boards that fail electrical testing or delaminate under thermal stress.

Tech Feature → Buyer Impact

| Technical Feature / Decision | Direct Impact (Yield/Reliability) |

|---|---|

| Drill Aspect Ratio > 10:1 | High risk of incomplete plating in via barrels (open circuits) and increased cost for specialized plating cycles. |

| Min Trace/Space < 4 mil | Exponentially lower yield due to etching defects; requires advanced HDI equipment and stricter AOI inspection. |

| Insufficient Solder Mask Dam (< 3 mil) | Solder bridging during assembly (shorts) because the mask cannot adhere to the substrate between pads. |

| Copper too close to board edge (< 10 mil) | Exposed copper during routing/depanelization, leading to corrosion or shorts to the chassis. |

Metrics That Matter (How to Evaluate It)

To master dfm guidelines for pcb layout, you must move beyond qualitative "good practices" and look at quantitative metrics. These are the numbers fabrication engineers look at when they review your Gerber files.

| Metric | Definition | Standard Capability | Advanced Capability (HDI) | Why It Matters |

|---|---|---|---|---|

| Aspect Ratio | PCB Thickness ÷ Drill Diameter | 8:1 or 10:1 | 12:1 to 20:1 | Determines if plating solution can flow through the hole to plate the walls. |

| Annular Ring | (Pad Diameter - Drill Diameter) ÷ 2 | 5 mil (0.127mm) | 3 mil (0.076mm) | Accounts for drill wander. If too small, the drill breaks out of the pad (tangency/breakout). |

| Trace/Space | Width of trace / Distance between copper | 5/5 mil | 3/3 mil or less | Determines etching yield. Tighter spacing increases risk of shorts; thinner traces increase risk of opens. |

| Solder Mask Web | Min distance between mask openings | 3-4 mil | 2-3 mil | Prevents solder bridges between pins on fine-pitch components (like QFPs). |

| Bow & Twist | Flatness of the board percentage | < 0.75% | < 0.5% | Critical for automated assembly (SMT). Warped boards cause placement errors. |

For designers working on high-density interconnects, understanding these ratios is vital. You can explore our HDI PCB capabilities to see how microvias change these metrics, allowing for tighter aspect ratios and finer lines.

How to Choose (Material & Design Selection)

The foundation of DFM starts before a single track is routed: it starts with the stackup and material selection. A common error is designing a stackup in CAD that uses unavailable core thicknesses or prepreg combinations that are difficult to laminate.

1. Material Selection (Tg and Cte)

For standard applications, FR4 is the default. However, "FR4" is a category, not a specific material. You must specify the Tg (Glass Transition Temperature).

- Standard Tg (130-140°C): Good for consumer electronics with standard lead-free soldering.

- High Tg (170°C+): Essential for automotive, industrial, or multilayer boards (>6 layers) to prevent Z-axis expansion which can crack plated through-holes (PTH).

If you are designing for high-frequency applications, standard FR4 dielectric loss might be too high. In these cases, you might look at Rogers or Teflon materials, but be aware: these materials are softer and harder to drill, requiring specific DFM adjustments in drill speeds and feeds.

2. Copper Weight vs. Spacing

This is a critical DFM rule: The heavier the copper, the wider the spacing must be. Etching is a subtractive process. To etch through 2oz (70µm) of copper takes longer than 1oz (35µm). As the etchant eats down, it also eats sideways (undercut).

- 1oz Copper: Min space usually 4-5 mil.

- 2oz Copper: Min space usually 8-10 mil.

- 3oz+ Copper: Min space 12-15 mil+.

If you design a power board with 3oz copper but keep 5 mil spacing, the manufacturer cannot etch it cleanly without causing shorts. Always consult our Heavy Copper PCB guidelines if you are moving high current.

Implementation Checkpoints (from Design to Fab)

Implementing dfm guidelines for pcb layout is a workflow, not a one-time check. We recommend breaking the process down into four distinct phases.

Implementation Roadmap

From Concept to Production

Before routing, input the manufacturer's capabilities into your CAD DRC. Set min trace width, clearance, and via sizes based on the "Standard" column of your fab house to avoid cost premiums. Define your layer stackup now.

Place connectors and mounting holes first. Ensure components are oriented consistently (pin 1 direction) to aid inspection. Leave 2-3mm clearance from board edges for conveyor rails or panelization tabs.

Route critical signals first. Use teardrops on via exits to strengthen the connection against drill breakout. Balance copper distribution on layers to prevent warping (bow and twist) during the heating cycle.

Run a final DRC. Check for "slivers" (tiny copper islands) and acid traps. Export Gerbers (RS-274X) and Drill files. View them in a 3rd party viewer to confirm the output matches your intent.

Common Mistakes (and How to Avoid Them)

Even experienced engineers fall into specific traps. Here are the most frequent issues we see at the APTPCB CAM station:

1. Acid Traps

When traces meet at acute angles (less than 90 degrees), acid can get trapped in the corner during the etching process. This residual acid can continue to eat away the copper over time, causing an open circuit.

- Fix: Always route at 45-degree or 90-degree angles. If an acute angle is necessary, curve the trace.

2. Insufficient Annular Ring

The annular ring is the copper pad area remaining around a drilled hole. Mechanical drills wander slightly (tolerance). If the ring is too small (e.g., < 4 mil), the drill might hit the edge of the pad or break out completely, severing the connection.

- Fix: For a 10 mil drill, use at least an 18-20 mil pad. See our PCB Drilling guide for tolerance charts.

3. Missing Solder Mask Dams

On fine-pitch components, if the space between pads is too small, the solder mask cannot be printed there. This creates a "gang opening." During assembly, solder will flow between pins, causing shorts.

- Fix: Ensure at least 3-4 mils of space between the copper of adjacent pads to allow for a solder mask dam.

4. Copper to Edge Violations

Placing copper too close to the board outline (routing path) or V-score line. The mechanical router can tear the copper, or the exposed copper can oxidize.

- Fix: Keep copper 10-20 mils (0.25mm - 0.5mm) away from the board edge.

Supplier Qualification Checklist: How to Vet Your Fab

Before you finalize your design, you need to know if your manufacturer can build it. Send this checklist to your potential partner (or check it against APTPCB's capabilities):

- What is your minimum Trace/Space for 1oz copper? (Standard is usually 5/5 mil; advanced is 3/3 mil).

- What is your maximum Aspect Ratio for plated through-holes? (Ensures they can plate your thick boards).

- Do you perform Automated Optical Inspection (AOI) on inner layers? (Critical for multilayer reliability).

- What is your drill positional tolerance? (Helps you calculate required annular ring).

- Do you support my required stackup and impedance control? (Ask for a stackup simulation report).

- What are your requirements for Via-in-Pad? (Do they require resin plugging and capping?).

- Do you perform cross-section analysis to verify plating thickness?

Glossary

Annular Ring: The ring of copper around a plated through-hole. It is the pad diameter minus the drill diameter, divided by two. It ensures the drill makes a solid connection to the trace.

Aspect Ratio: The ratio of the PCB thickness to the diameter of the drilled hole. A high aspect ratio (e.g., 10:1) makes it difficult to plate copper inside the hole barrel reliably.

Acid Trap: An acute angle in a copper trace that can trap etching acid during manufacturing, potentially causing the trace to corrode and open over time.

Fiducial Marker: A specific optical marker (usually a round copper pad) placed on the PCB panel to help assembly machines (Pick and Place) align the board accurately.

Solder Mask Sliver: A narrow strip of solder mask. If too thin, it can flake off during manufacturing and land on pads, preventing soldering.

6 Essential Rules for DFM Guidelines for PCB Layout (Cheat Sheet)

| Golden Rule | Why It Matters | Implementation Key |

|---|---|---|

| 1. The "5/5" Rule | Standard etching capability for 1oz copper. | Keep Trace/Space ≥ 5 mil for standard cost. |

| 2. Annular Ring Safety | Prevents drill breakout (open circuits). | Pad size = Drill size + 10 mil (min). |

| 3. Edge Clearance | Prevents copper tearing during routing. | Keep copper > 10 mil (0.25mm) from edge. |

| 4. Aspect Ratio < 8:1 | Ensures reliable barrel plating. | For 1.6mm board, min via drill 0.2mm. |

| 5. Solder Mask Dams | Prevents assembly shorts. | Min 3-4 mil mask web between pads. |

| 6. Balance Copper | Prevents board warping (bow/twist). | Use copper pours on empty areas of layers. |

FAQ

Q: What is the difference between DRC and DFM?

A: DRC (Design Rule Check) is a software check within your CAD tool to ensure the design meets logical electrical rules (e.g., no shorts). DFM (Design for Manufacturing) is a broader check to ensure the design fits the physical manufacturing process capabilities (e.g., acid traps, drill tolerance, plating feasibility). Passing DRC does not guarantee passing DFM.

Q: How does copper weight affect my layout DFM?

A: Heavier copper (e.g., 2oz or 3oz) requires wider spacing between traces. Because etching is isotropic (eats in all directions), thicker copper requires more time in the etchant, leading to more "undercut." If traces are too close, they will not etch completely, causing shorts. You generally need 2-3 mils of extra spacing for every ounce of copper added.

Q: Can I place vias inside component pads (Via-in-Pad)?

A: Yes, but it requires specific manufacturing steps. If you leave an open via in a pad, solder will wick down the hole during assembly, starving the joint. You must specify "Via-in-Pad Plated Over" (POFV), where the manufacturer plugs the via with resin, cures it, and plates copper over it to create a flat surface. This adds cost but is essential for HDI designs.

Q: What is the standard drill tolerance I should account for?

A: For mechanical drilling, the standard tolerance is usually ±3 mil (0.075mm). This is why an annular ring of at least 5-6 mil is recommended for standard boards. Laser drilling (for microvias) has much tighter tolerances but is used for specific HDI stackups.

Q: Why do I need teardrops on my vias?

A: Teardrops add extra copper at the junction where the trace meets the via pad. This provides mechanical reinforcement. If the drill wanders slightly and breaks out of the pad, the teardrop ensures the connection to the trace remains intact, preventing an open circuit.

Q: How do I handle DFM for flex PCBs compared to rigid PCBs?

A: Flex PCBs have unique DFM rules. You must avoid sharp corners in traces to prevent stress cracking, use "anchors" (spurs) for pads to prevent them from peeling off the polyimide, and ensure the coverlay openings are sized correctly. Refer to our Flex PCB capabilities for specific bend radius and trace routing guidelines.

Request a Quote / DFM Review for DFM Guidelines for PCB Layout

Ready to move your design from screen to production? At APTPCB, we perform a comprehensive DFM review on every order to catch issues before they become costly scrap.

To get a precise quote and DFM check, please provide:

- Gerber Files: RS-274X format (preferred).

- Drill Files: Excellon format (include a drill map).

- Fabrication Drawing: Specifying board thickness, copper weight, surface finish (e.g., ENIG, HASL), and solder mask color.

- Stackup Details: If you have specific impedance requirements.

- Quantities: Prototype vs. Mass Production volumes.

>> Get Your Instant Quote & DFM Review Here

Conclusion

Mastering dfm guidelines for pcb layout is the hallmark of a professional PCB designer. It shifts the focus from "making it connect" to "making it buildable." By adhering to proper aspect ratios, respecting copper-to-edge clearances, and understanding the chemical realities of etching, you ensure high yields, lower costs, and faster time-to-market.

At APTPCB, we are more than just a factory; we are your engineering partner. Whether you are building a simple 2-layer prototype or a complex Rigid-Flex PCB, our team is here to guide you through the manufacturing process. Don't leave your board's success to chance—design with manufacturing in mind.