Drone PCB manufacturing requires specialized expertise balancing ultra-lightweight construction, vibration and shock resistance, electromagnetic compatibility, and thermal management across flight controllers, ESCs, power distribution, FPV systems, and telemetry modules supporting consumer quadcopters, commercial inspection drones, and military surveillance UAVs operating in demanding environments from arctic conditions through desert heat requiring reliable electronics surviving thousands of flight cycles through temperature extremes, vibration, and electromagnetic interference.

At APTPCB, we manufacture drone PCBs with drone UAV industry expertise implementing lightweight materials, ruggedized construction, and comprehensive testing protocols. Our capabilities support racing drones requiring ultra-compact high-current ESCs through commercial inspection platforms demanding reliable long-endurance operation with validated manufacturing processes ensuring quality and performance.

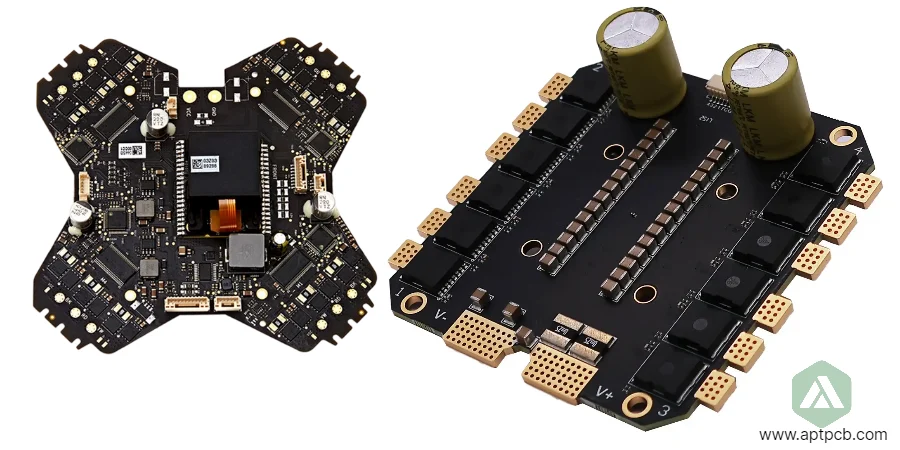

Achieving Ultra-Lightweight High-Density Designs

Every gram of electronics weight directly reduces flight time, payload capacity, or requires larger batteries increasing overall system weight creating vicious cycle limiting drone performance. Achieving <10g flight controller or <5g ESC weights while maintaining reliability, current handling capability, and electromagnetic compatibility presents significant design challenges. Inadequate weight optimization forces compromises in battery capacity reducing flight time, limits payload capacity affecting commercial viability, or requires oversized motors and props increasing power consumption — directly impacting drone performance and operational economics.

At APTPCB, our manufacturing implements advanced lightweight construction techniques achieving industry-leading power-to-weight ratios.

Key Lightweight Design Techniques

- Thin PCB Substrates: 0.6-0.8mm PCB thickness reducing weight 20-30% compared to standard 1.6mm boards while maintaining adequate mechanical strength through aerospace defense grade materials.

- High-Density Component Integration: 0201 or 01005 passive components, CSP ICs, and micro-BGAs maximizing functional density while minimizing board area and weight.

- Optimized Copper Distribution: Strategic copper removal from non-critical areas reducing weight while maintaining adequate current handling and thermal performance in power distribution paths.

- Material Selection: Lightweight core materials or thin prepreg stackups achieving required dielectric properties with minimal weight penalty.

- Miniaturized Connectors: Ultra-compact board-to-board connectors or direct soldering eliminating heavy traditional connectors where possible.

- Weight-Critical Tolerance Control: Manufacturing process controls ensuring consistent thickness and copper weight achieving target weight specifications through quality system validation.

Validated Lightweight Performance

By implementing comprehensive weight optimization strategies, advanced manufacturing techniques, and rigorous weight validation supported by precision manufacturing processes, APTPCB enables drone PCB designs achieving target weight specifications supporting maximum flight time, payload capacity, and operational performance across consumer, commercial, and specialty UAV applications.

Managing Vibration and Mechanical Shock Resistance

Drone electronics experience severe vibration from motor imbalance, propeller resonance, and aerodynamic turbulence plus hard landings or crashes creating shock loads potentially causing solder joint failures, component cracking, or connector disconnection. Inadequate mechanical robustness causes intermittent failures from vibration-induced connection problems, sudden failures from shock damage, or progressive fatigue failures from accumulated stress cycles — significantly impacting reliability, operational safety, and maintenance costs requiring frequent repairs or replacements.

At APTPCB, our manufacturing implements validated ruggedization techniques ensuring mechanical reliability.

Key Vibration Resistance Techniques

- Underfill and Potting Materials: Selective underfill on high-stress components (BGAs, large ICs) or complete board potting using flexible polyurethane preventing solder joint fatigue and component damage.

- Component Mounting Optimization: Strategic placement of heavy components near PCB centers minimizing bending moments and selecting components with robust package construction surviving vibration environments.

- Reinforced Solder Joints: Controlled solder profile optimization and proper pad design achieving reliable mechanical and electrical connections surviving millions of vibration cycles.

- Flexible PCB Integration: Strategic use of flexible circuits or rigid-flex construction accommodating relative motion between assemblies without inducing mechanical stress.

- Connector Selection and Locking: Vibration-resistant connectors with positive locks preventing disconnection plus strain relief preventing cable fatigue failures.

- Validation Testing: Vibration and shock testing per MIL-STD-810 or RTCA DO-160 protocols validating mechanical robustness supporting commercial and military applications through testing quality standards.

Mechanical Reliability Assurance

Through ruggedized construction techniques, validated component selection, and comprehensive mechanical testing supported by experienced manufacturing teams, APTPCB delivers drone PCBs achieving mechanical reliability specifications supporting reliable operation in demanding flight environments across diverse UAV applications and mission profiles.

Implementing EMI Control for Reliable RF Performance

Drone electronics integrate multiple RF systems (control link, video transmission, GPS, telemetry) operating simultaneously while high-current ESCs generate substantial electromagnetic interference potentially causing GPS loss, video static, or control link degradation. Inadequate EMI management causes intermittent control loss risking crashes, degraded video quality affecting commercial inspection operations, or GPS position errors compromising autonomous navigation — directly impacting operational safety, mission success, and regulatory compliance with FCC or CE EMC requirements.

At APTPCB, our manufacturing implements comprehensive EMI control strategies ensuring reliable RF coexistence.

Key EMI Management Techniques

- Strategic Shielding Implementation: Localized shielding cans over sensitive RF circuits (GPS, receivers) or complete board shields protecting against interference from ESC switching noise.

- Multi-Layer Stackup Optimization: Solid ground planes beneath RF traces providing return paths while creating electromagnetic barriers between noisy power sections and sensitive RF circuits.

- Component Placement Strategy: Physical separation between noisy circuits (ESCs, switching regulators) and sensitive RF circuits (GPS, receivers, video transmitters) minimizing coupling.

- Filtered Power Distribution: LC or pi-filters on power supplies feeding RF circuits preventing switching noise propagation through power rails.

- PCB Edge Grounding: Multiple ground vias along board perimeters creating electromagnetic barriers reducing emissions and preventing external interference ingress.

- Pre-Compliance Testing: EMI scanning during development identifying problem areas enabling optimization before flight testing through functional testing protocols.

RF Performance Assurance

By implementing comprehensive EMI control strategies, validated shielding techniques, and RF performance testing coordinated with manufacturing processes, APTPCB enables drone PCBs achieving reliable RF coexistence supporting simultaneous operation of control, video, GPS, and telemetry systems across diverse operational environments.

Ensuring Thermal Management in Compact Enclosures

Drone electronics dissipate 10-50W in compact volumes with limited airflow requiring efficient heat dissipation preventing overheating causing premature component failures, thermal shutdowns during flight, or reduced performance from thermal throttling. Inadequate thermal design causes ESC overheating limiting current capacity affecting flight performance, flight controller overheating causing sensor drift affecting stability, or battery management failures causing dangerous conditions — directly impacting flight safety, performance, and operational reliability.

At APTPCB, our manufacturing implements effective thermal strategies maintaining safe component temperatures.

Thermal Management Techniques

- Thermal Via Arrays: Dense via patterns beneath power components transferring heat through PCB to opposite side or mounting structures improving heat dissipation in double-sided assemblies.

- Heavy Copper Construction: 2-4oz copper in power paths improving lateral heat spreading while handling high continuous currents in ESC and power distribution boards.

- Heat Spreading Planes: Internal copper planes distributing heat across board area preventing localized hot spots and utilizing full board area for heat dissipation.

- Thermal Interface to Frame: Proper mounting ensuring thermal contact between PCB and drone frame utilizing carbon fiber or aluminum structures as heat sinks.

- Component Selection: Thermally-efficient components with low Rds(on) MOSFETs minimizing losses and ICs with thermal shutdown protection preventing damage from overheating.

- Thermal Testing Validation: Thermal imaging under flight-representative loads validating component temperatures remain within specifications throughout flight envelope.

Thermal Performance Validation

Through comprehensive thermal design, validated heat dissipation techniques, and thorough thermal testing coordinated with manufacturing processes, APTPCB enables drone PCBs maintaining safe operating temperatures supporting sustained high-power operation across consumer, commercial, and specialty UAV applications.

Providing Waterproofing and Environmental Protection

Commercial and military drones operate in diverse environments including rain, snow, humidity, dust, and salt spray requiring electronics protection preventing corrosion, short circuits, or insulation degradation. Inadequate environmental protection causes premature failures from moisture ingress, corrosion on exposed conductors, or contamination affecting sensors and connectors — significantly impacting operational reliability, maintenance costs, and mission availability especially for inspection, agriculture, or maritime applications requiring operation in challenging environmental conditions.

At APTPCB, our manufacturing implements environmental protection ensuring reliable operation across diverse conditions.

Environmental Protection Techniques

- Conformal Coating Application: Acrylic, polyurethane, or parylene coatings protecting circuits from moisture, dust, and chemical exposure while maintaining electrical performance through PCB conformal coating processes.

- Potting and Encapsulation: Complete board potting using flexible materials providing maximum environmental protection for critical electronics in harsh-environment applications.

- Connector Sealing: Sealed connectors with O-rings or gaskets preventing moisture ingress at cable interfaces plus proper strain relief preventing water intrusion from cable movement.

- Corrosion-Resistant Finishes: ENIG, immersion silver, or OSP surface finishes providing long-term corrosion resistance in humid or salt environments.

- IP Rating Validation: Environmental testing per IP standards (IP54, IP65, IP67) validating protection against dust and water ingress supporting various operational requirements.

- Material Selection: Components rated for extended temperature and humidity ranges (-40 to +85°C, 95% RH) ensuring reliable operation across environmental extremes.

Environmental Reliability

Through comprehensive environmental protection strategies, validated coating processes, and environmental testing supported by manufacturing expertise, APTPCB enables drone PCBs achieving IP ratings and environmental specifications supporting reliable operation across commercial inspection, agriculture, maritime, and military UAV applications in challenging environmental conditions worldwide.

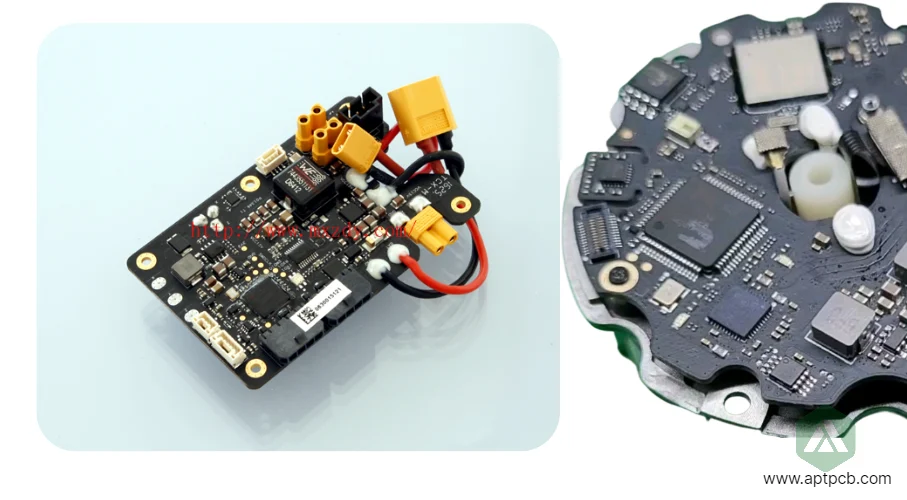

Supporting Diverse UAV Applications and Customization

Drone PCBs serve diverse applications from consumer FPV racing requiring ultra-compact high-current electronics through commercial inspection platforms demanding reliable sensors and long-endurance operation to military ISR systems requiring secure communications and extended mission capabilities. Application-specific requirements drive customization in form factor, interface protocols, sensor integration, and certification requirements necessitating flexible manufacturing supporting rapid prototyping through volume production.

At APTPCB, we provide comprehensive drone PCB manufacturing supporting diverse applications.

Application Support Capabilities

Consumer and Racing Drones

- Ultra-compact high-current ESCs (30-60A continuous) in minimal footprints supporting aggressive flight maneuvers and fast response.

- Lightweight flight controllers (<10g) integrating gyroscopes, accelerometers, barometers, and microcontrollers supporting advanced flight modes.

- FPV systems integrating cameras, video transmitters, and OSD circuits supporting immersive first-person flight experience.

- Cost optimization achieving competitive consumer pricing while maintaining performance and reliability specifications.

Commercial and Industrial UAVs

- Industrial-grade components and environmental protection supporting IP ratings for inspection, agriculture, and surveying applications.

- Long-endurance optimization prioritizing efficiency over peak performance supporting extended mission times.

- Sensor integration supporting cameras, multispectral sensors, LiDAR, or specialized payload interfaces enabling diverse commercial applications.

- Certification support (FCC, CE, FAA Part 107) enabling commercial operations across regulated markets.

Through application-specific optimization, flexible manufacturing capabilities, and comprehensive support services coordinated with robotics industry expertise, APTPCB enables drone manufacturers deploying reliable electronics across consumer, commercial, military, and specialty UAV markets supporting diverse mission requirements and operational environments worldwide.