Contents

- The Context: What Makes Drop Test Setup Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Drop Test Setup (What to Send)

- Conclusion

A drop test setup is the engineered configuration—comprising the drop tester, fixture, data acquisition system, and sensor array—designed to simulate these impact events in a controlled, repeatable manner. It is not merely dropping a product on the floor; it is a precise science of measuring G-forces, pulse durations, and PCB strain to ensure that the interconnects (solder joints, vias, and traces) can survive the sudden deceleration of impact.

For engineers and manufacturers, a "good" setup is defined by its ability to isolate variables. It must distinguish between a failure caused by a brittle solder joint and a failure caused by poor enclosure design. It requires a balance of rigid fixturing to transmit shock and realistic mounting to simulate actual use, ensuring that the data collected correlates directly to field survival rates.

Highlights

- Pulse Shaping is Critical: The difference between a 0.5ms half-sine pulse and an 11ms pulse fundamentally changes how the PCB flexes and which failure modes are triggered.

- Fixture Stiffness: In board-level testing (JEDEC), the fixture must be significantly stiffer than the PCB to ensure the board bends due to its own inertia, not fixture resonance.

- Strain vs. Shock: High G-force (shock) rarely breaks solder joints directly; it is the secondary bending (strain) of the PCB that shears the intermetallic connections.

- Event Detection: A robust setup uses high-speed resistance monitoring (daisy chains) to detect micro-second discontinuities that disappear once the board settles.

The Context: What Makes Drop Test Setup Challenging

The primary challenge in configuring a drop test setup lies in the transient nature of the event. An impact lasts only milliseconds, yet within that window, complex stress waves propagate through the device casing, into the mounting points, and across the PCB.

As electronics become denser, the margin for error shrinks. Modern Ball Grid Arrays (BGAs) and Chip Scale Packages (CSPs) have smaller solder balls and tighter pitches. This reduction in interconnect volume means there is less metal to absorb the strain energy during a drop. Consequently, the drop test setup must be sensitive enough to detect the initiation of cracks in these microscopic joints.

Furthermore, the industry faces a dichotomy between standardization and realism. Standards like JEDEC JESD22-B111 provide a strict baseline for comparing solder alloys and laminate materials using a standardized board design. However, these standards do not perfectly mimic the complex harmonics of a real product enclosure. Engineers at APTPCB (APTPCB PCB Factory) often have to navigate this trade-off, designing setups that satisfy industry compliance while also providing data relevant to the specific product's geometry and mass distribution.

Cost and lead time also play a role. Building custom fixtures for every product variant is expensive. A modular setup that allows for rapid changeover between different form factors without compromising the rigidity of the mount is a significant engineering hurdle.

The Core Technologies (What Actually Makes It Work)

A successful drop test setup relies on the integration of several distinct technologies. It is a system where mechanical engineering meets high-speed data acquisition.

The Drop Tester and Pulse Shapers The machine itself is usually a guided rail system or a free-fall tower. The critical component, however, is the "pulse shaper"—the material the drop table strikes.

- Felt or Rubber Pads: Used to create longer duration pulses (e.g., 11ms) typical of shipping handling.

- Hard Plastics or Steel: Used to create short, high-G pulses (e.g., 0.5ms, 1500G) typical of dropping a phone on concrete.

- Brake Systems: A secondary braking mechanism is essential to catch the drop table on the rebound, preventing a "double hit" that would corrupt the data.

Instrumentation and Sensors

- Accelerometers: Piezoelectric sensors are mounted on the drop table (to measure input G) and often on the PCB itself (to measure response G). Their bandwidth must be sufficient to capture high-frequency harmonics.

- Strain Gauges: These are glued to the PCB at critical stress points (usually corners of large BGAs). They measure the actual bending of the board. Since PCB quality depends on minimizing this strain, these gauges provide the most actionable data for layout improvements.

High-Speed Data Acquisition (DAQ) The DAQ system must sample at a rate high enough to capture the peak of the shock pulse without aliasing. For a 0.5ms pulse, a sampling rate of at least 100kHz to 1MHz is often required. This system also monitors the electrical continuity of the "daisy chain" nets on the PCB. A "failure" is often defined as a resistance spike exceeding 1000 ohms for a duration as short as 1 microsecond.

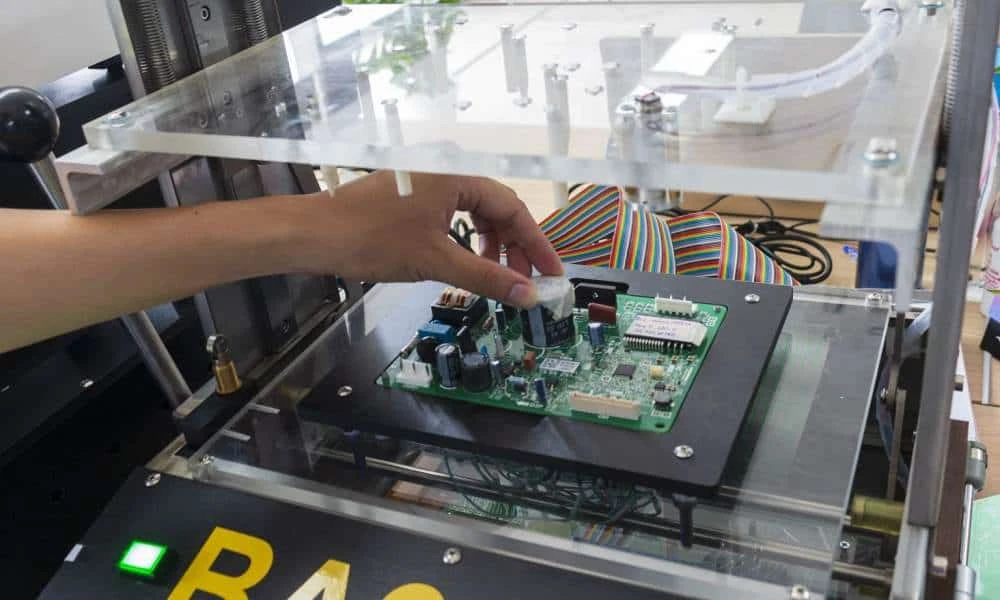

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

The drop test setup does not exist in a vacuum; it is deeply connected to the upstream design and manufacturing choices.

Material Selection and Stackup The stiffness of the PCB material affects how much it bends during impact. A high-Modulus material or a thicker core can reduce flexing, potentially saving the solder joints. Conversely, a thinner, more flexible board might require underfill to survive. When selecting materials, such as High Tg PCB laminates, engineers must consider their fracture toughness, not just their thermal properties.

Surface Finishes and Intermetallics The interface between the solder ball and the PCB pad is the weakest link during a drop.

- ENIG (Electroless Nickel Immersion Gold): While excellent for flatness, the nickel-tin intermetallic can be brittle.

- OSP (Organic Solderability Preservative): Often provides a copper-tin intermetallic that is more ductile and resistant to shock, though it has a shorter shelf life.

- Immersion Silver: Offers a middle ground but requires careful handling. Understanding these trade-offs is vital when specifying the PCB surface finishes for a ruggedized product.

Assembly Process Variables The reflow profile used during SMT assembly dictates the grain structure of the solder joint. A profile that cools too slowly can create large grain structures that are weaker against mechanical shock. Additionally, the presence of voids (air bubbles) in the solder joint can act as stress concentrators. APTPCB emphasizes that a robust drop test result is often a validation of the process window as much as the design itself.

Comparison: Common Options and What You Gain / Lose

When establishing a drop test setup, engineers usually choose between a standardized "Board-Level" approach and a "Product-Level" approach. There is also a choice regarding the depth of instrumentation.

Board-Level (JEDEC Style) vs. Product-Level

- Board-Level: The PCB is mounted to a rigid fixture with standoffs. This isolates the PCB performance. It is excellent for comparing different solder alloys or underfills but ignores the damping provided by a plastic housing.

- Product-Level: The entire device is dropped. This is realistic but chaotic. The battery might rattle, the casing might absorb energy, or the screen might crack before the board fails.

Instrumentation Depth

- Basic: Accelerometer on the table only. Tells you "it was dropped at 1000G."

- Advanced: Strain gauges on the board + in-situ resistance monitoring. Tells you "the board bent 1500 micro-strain, causing U12 to fail at the 3rd drop."

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| Rigid 4-Point Fixture (JEDEC) | Maximizes board flex; ideal for worst-case solder joint validation. |

| Full Product Drop | Includes enclosure damping; realistic but harder to pinpoint root cause. |

| Daisy Chain Monitoring | Detects transient "open" circuits that reconnect after the event. |

| High-Speed Camera | Visualizes mode shapes and secondary impacts (slap-down). |

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

To ensure a drop test setup delivers valid results, specific pillars of performance must be controlled.

Signal Integrity of the Test Loop The "signal" in a drop test is the resistance of the daisy chain. The DAQ system must be immune to the mechanical noise of the impact. Cables must be strain-relieved so that the whip of the cable doesn't pull on the connector or generate triboelectric noise (charge generated by friction) that masks the data.

Thermal Considerations Drop testing is often performed at room temperature, but reliability demands testing at extremes. A solder joint that survives at 25°C might fail at -20°C due to the embrittlement of materials. Advanced setups include thermal chambers that enclose the drop table, allowing for impact testing under thermal load. This is crucial for automotive electronics PCB applications where cold-drop performance is a safety requirement.

Process Control and Repeatability The drop tester must be calibrated. If the guide rails are dirty or the pulse shaper is worn out, the G-force profile will drift. A 1500G pulse might degrade to 1200G, giving a false sense of security. Regular calibration of the accelerometer and the machine mechanics is essential for maintaining the integrity of the testing quality.

Acceptance Criteria A typical pass/fail criterion involves:

- Electrical: No resistance spikes >1000Ω for >1µs.

- Mechanical: No visible cracking of the laminate or components.

- Statistical: The "First Failure" usually dictates the limit, but Weibull analysis is used to predict the B10 or B1 life (when 10% or 1% of the population will fail).

The Future: Where This Is Going (Materials, Integration, Ai/automation)

The future of drop testing is moving from purely physical iteration to a hybrid of simulation and validation. Finite Element Analysis (FEA) is becoming accurate enough to predict where strain gauges should be placed, reducing the number of trial drops required.

Furthermore, the integration of non-destructive testing is improving. Instead of physically cross-sectioning a board after a drop test (which destroys the sample), high-resolution CT scans can now visualize micro-cracks inside the BGA balls while the board is still intact. This allows for "progressive" drop testing, where the same board is scanned, dropped again, and scanned again to track crack propagation.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Simulation Accuracy | Used for trends; requires physical validation. | Digital Twins replace 80% of physical tests. | Drastically reduces NPI lead time and prototype costs. |

| Sensor Integration | Wired accelerometers and strain gauges. | Wireless, embedded MEMS sensors. | Eliminates cable noise and drag; allows testing in sealed units. |

| Failure Analysis | Destructive (Dye & Pry, Cross-section). | In-line CT Scanning & AI detection. | Preserves samples for further testing; detects sub-surface defects. |

Request a Quote / DFM Review for Drop Test Setup (What to Send)

When engaging APTPCB for a project requiring drop test validation or a ruggedized design, providing specific details upfront ensures the manufacturing process aligns with your reliability goals. We need to understand not just the circuit, but the mechanical environment it must survive.

- Gerber Files: Standard RS-274X or ODB++ format.

- Stackup Requirements: Specify if high-modulus materials are needed for stiffness.

- Component BOM: Crucial for estimating the mass distribution on the board.

- Test Standard: Are you following JEDEC JESD22-B111, IEC 60068-2-31, or a custom profile?

- G-Force and Pulse Duration: E.g., "1500G, 0.5ms half-sine."

- Critical Components: Identify BGAs or heavy components that may require underfill or corner bonding.

- Daisy Chain Design: If you need a specific daisy chain test vehicle built, provide the netlist.

- Acceptance Criteria: Define what constitutes a failure (resistance threshold, cosmetic cracks, etc.).

Conclusion

The drop test setup is the gatekeeper of mechanical reliability. It transforms the chaotic violence of an impact into actionable data, allowing engineers to reinforce weak points before a product reaches the customer. Whether through optimizing the PCB stack-up, selecting the right surface finish, or applying underfill, the insights gained from a well-executed drop test are invaluable.

As devices continue to shrink and travel everywhere with us, the importance of this testing will only grow. By understanding the mechanics of the setup—from the pulse shaper to the strain gauge—you can design products that not only function electrically but endure physically. For robust manufacturing and expert guidance on ruggedized PCB assembly, contact APTPCB today.