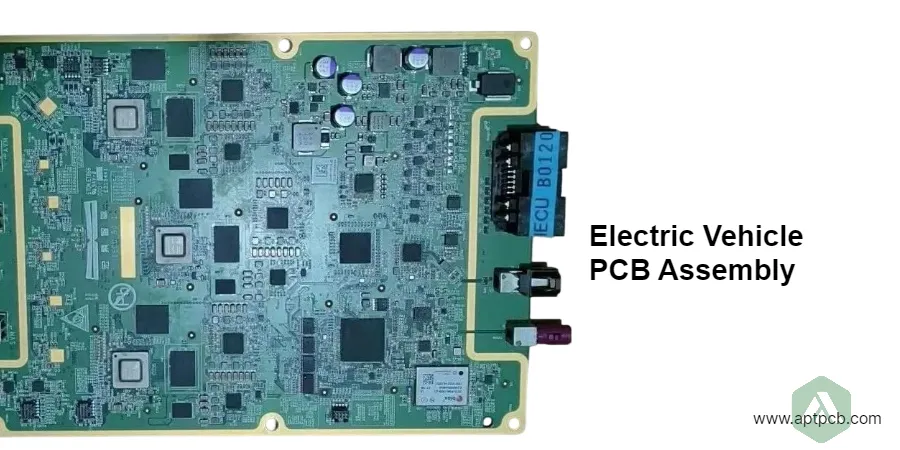

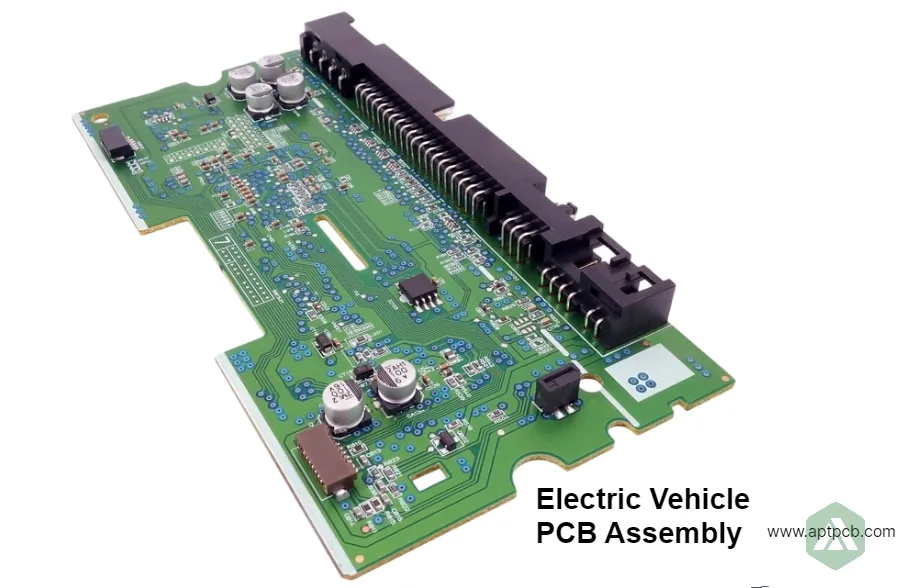

Electric vehicle PCB assemblies implement battery management, traction inverters, onboard chargers, and DC-DC converters handling 400-800V high-voltage systems requiring reinforced isolation, SiC power semiconductors, precision current/voltage measurement, and automotive functional safety supporting vehicle electrification across passenger EVs, commercial trucks, buses, and construction equipment demanding reliable operation through 20+ year vehicle lifecycles with millions of drive cycles.

At APTPCB, we deliver specialized EV assembly services implementing high-voltage isolation, power electronics, and automotive qualification with turnkey assembly capabilities supporting BMS through traction inverter applications.

Implementing High-Voltage Isolation and Safety

EV electronics interface between 400-800V battery systems and low-voltage control circuits requiring reinforced isolation (typically 4-6kV) preventing electric shock hazards while enabling precise measurement and control. Isolation challenges include creepage/clearance distances, high-voltage PCB materials, and isolation barrier validation. Inadequate isolation implementation creates shock hazards, prevents safety certification, or causes catastrophic failures — significantly impacting product safety and regulatory compliance.

At APTPCB, our assembly implements validated high-voltage isolation achieving automotive safety requirements.

High-Voltage Isolation Implementation

- Reinforced Isolation Design: >8mm creepage/clearance distances between HV and LV circuits per automotive safety standards with testing quality validation.

- Isolation Monitoring: Insulation resistance measurement detecting degradation before safety compromised.

- High-Voltage PCB Materials: Enhanced tracking resistance preventing surface breakdown under contamination.

- Isolation Testing: Hipot testing at 2x working voltage + 2kV validating dielectric integrity.

- Interlocks and Detection: HV presence detection and connector interlocks preventing access during operation.

Validated HV Safety

Through automotive safety expertise and comprehensive isolation testing, APTPCB enables EV electronics meeting high-voltage safety requirements.

Integrating SiC Power Electronics

Silicon carbide power semiconductors enable 150kW+ traction inverters in compact packages operating at 150-200°C junction temperatures improving efficiency 2-3% versus IGBTs. SiC integration challenges include ultra-fast switching managing EMI, gate drive design for wide bandgap devices, and thermal management at elevated temperatures. Inadequate SiC implementation limits efficiency gains, causes EMI issues, or reduces reliability — significantly impacting EV range and competitiveness.

At APTPCB, our manufacturing supports SiC power electronics achieving >99% inverter efficiency.

SiC Integration Implementation

- SiC MOSFET/Module Assembly: Precision mounting maintaining thermal interfaces for 150kW+ power modules.

- Gate Drive Design: Isolated gate drivers managing dv/dt >50kV/μs preventing parasitic turn-on.

- EMI Management: Shielding and filtering controlling emissions from 100kHz+ switching frequencies.

- Thermal Interface: Phase-change or liquid cooling interfaces managing junction temperatures <175°C.

- High-Temperature Components: 150-175°C rated components surviving underhood environments.

Through SiC expertise coordinated with functional testing validation, APTPCB enables next-generation EV powertrains achieving premium efficiency.

Supporting Battery Management Systems

BMS electronics monitor hundreds of cells managing charging, balancing, and protection requiring precision measurement (<10mV voltage, <100mA current accuracy), robust communication, and fail-safe operation. BMS challenges include scalability across cell counts, thermal management of balancing circuits, and safety-critical protection functions. Inadequate BMS implementation causes range inaccuracy, cell degradation from improper balancing, or safety incidents from protection failures — significantly impacting vehicle safety and battery longevity.

At APTPCB, we support BMS manufacturing achieving precision measurement and automotive reliability.

BMS Implementation

- Multi-Cell Monitoring: Cascaded AFE ICs monitoring 12-18 cells per IC scaling to 100+ cell packs.

- Precision Voltage Measurement: <10mV accuracy enabling accurate SOC/SOH estimation.

- Active/Passive Balancing: Cell balancing circuits optimizing pack capacity and longevity.

- Isolation and Communication: Isolated CAN/SPI communication maintaining safety barriers.

- Functional Safety: ASIL-C/D implementation with redundant monitoring and safe-state management.

Through BMS expertise and automotive qualification, APTPCB enables reliable battery systems supporting EV performance and safety.

Providing EV Charging Systems Integration

Onboard chargers convert AC to DC charging 400-800V batteries at 3-22kW while DC fast charging electronics manage 50-350kW power transfer requiring PFC, isolation, and battery communication. Charging challenges include universal input compatibility, efficiency >95%, and communication protocol support. Inadequate charging implementation causes slow charging, compatibility issues, or inefficiency reducing range — significantly impacting charging experience and vehicle utility.

At APTPCB, we support EV charging manufacturing across onboard and DC fast charging applications.

Charging System Implementation

Onboard Chargers

- PFC boost converter achieving >0.99 power factor across 85-265VAC inputs.

- Isolated DC-DC converter delivering regulated voltage/current to battery.

- CCS/CHAdeMO communication implementing charging protocols.

- Thermal management maintaining <85°C component temperatures in underhood installation.

DC Fast Charging

- High-power rectification and filtering managing 50-350kW power levels.

- Battery communication coordinating charge parameters and monitoring.

- Liquid cooling managing kW-level heat dissipation.

- Safety interlocks and monitoring ensuring safe high-power operation.

Through charging expertise coordinated with quality system compliance, APTPCB enables comprehensive EV charging solutions.