Energy storage system PCB assemblies enable bidirectional power conversion between battery packs and AC grids or solar arrays, implementing sophisticated energy management, grid-interactive controls, and battery protection across residential, commercial, and utility-scale installations. These assemblies integrate power electronics, digital control, communication interfaces, and safety systems requiring precision manufacturing and comprehensive validation supporting 10-15 year operational lifetimes.

At APTPCB, we deliver specialized energy storage assembly services combining high-power electronics manufacturing, control system integration, and validated testing. Our capabilities support battery inverters, hybrid inverters, and grid-interactive ESS serving diverse energy storage applications.

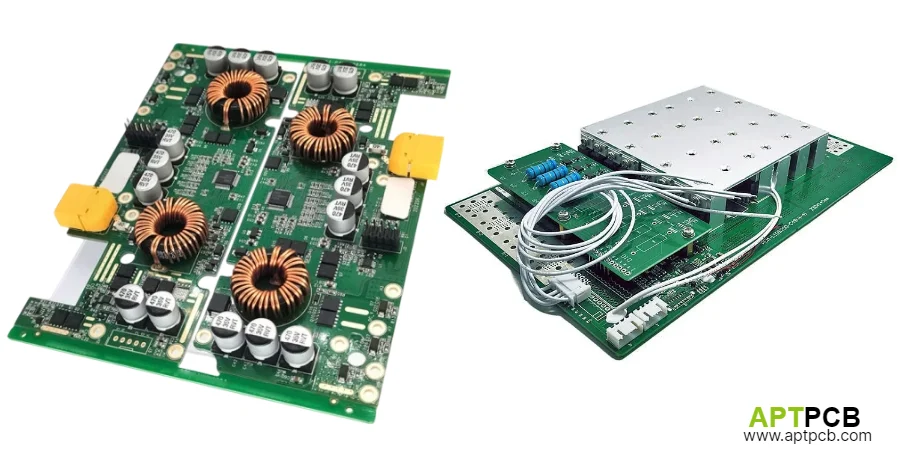

Implementing Bidirectional Power Conversion Electronics

ESS assemblies must efficiently convert DC battery power to AC grid voltage (discharge) and AC grid power to DC battery charging (charge) maintaining >95% round-trip efficiency. Bidirectional operation requires sophisticated power stage design, control algorithms, and protection circuits managing power flow in both directions.

At APTPCB, our assembly expertise implements reliable bidirectional power electronics.

Key Bidirectional Conversion Features

- Synchronous Power Stage: Four-quadrant power conversion using IGBT or MOSFET bridges enabling efficient bidirectional power flow with minimal switching losses.

- Inductor and Filter Design: Turnkey assembly implementing output filters managing harmonic currents and achieving grid power quality compliance.

- DC Bus Capacitors: High-voltage capacitor banks providing energy buffering and supporting rapid power transitions during load changes.

- Thermal Management: Heat dissipation strategies maintaining safe operating temperatures during continuous charge-discharge cycling at rated power.

- Gate Drive Circuits: High-reliability gate drivers ensuring proper IGBT/MOSFET switching preventing shoot-through or cross-conduction failures.

- Protection Implementation: Overcurrent, overvoltage, and short circuit protection preventing damage during fault conditions or grid disturbances.

High-Efficiency Energy Transfer

Through precision assembly and testing quality validation, APTPCB delivers power electronics achieving >97% conversion efficiency maximizing usable energy storage capacity.

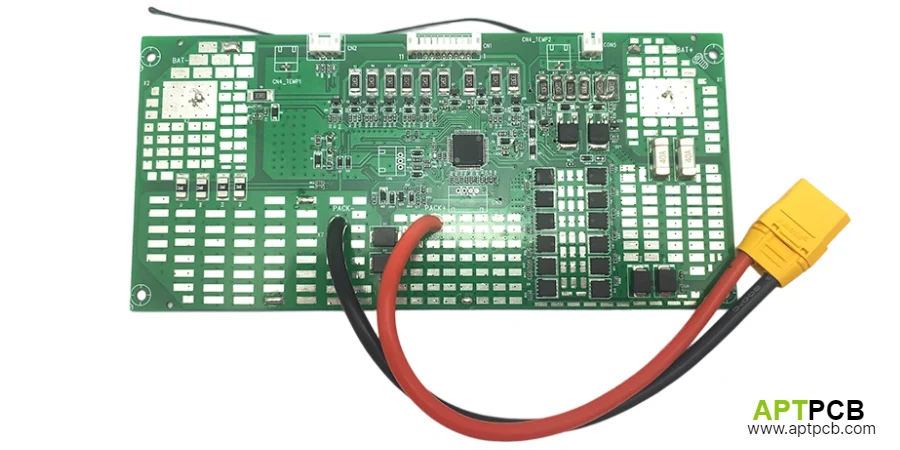

Integrating Battery Management System Interface

ESS assemblies communicate with battery management systems (BMS) coordinating state-of-charge, voltage limits, current limits, and protection status ensuring safe battery operation and maximizing cycle life. Proper BMS integration prevents battery damage, thermal events, and premature capacity degradation.

APTPCB implements comprehensive BMS interface capabilities.

Key BMS Integration Features

- CAN Bus Communication: High-reliability CAN interface exchanging real-time battery parameters between BMS and power conversion control.

- Safety Interlock: Hardware safety interlocks immediately shutting down power conversion upon BMS fault detection preventing hazardous conditions.

- State Management: Coordinated state machines managing charge, discharge, standby, and fault conditions based on BMS commands and grid status.

- Current Limiting: Dynamic current limit adjustment based on BMS-reported battery temperature, SOC, and health maintaining safe operation.

- Voltage Regulation: Precise DC bus voltage control respecting BMS-defined charging voltage limits across battery chemistries and operating conditions.

- Fault Coordination: Comprehensive fault handling coordinating between power electronics, BMS, and grid interface ensuring safe shutdown sequences.

Safe Battery Integration

By implementing robust BMS interfaces through IC programming and validated testing, APTPCB enables ESS assemblies protecting battery investments and ensuring safe operation.

Providing Grid-Interactive Control and Compliance

Modern ESS systems provide advanced grid services—frequency regulation, peak shaving, load shifting, backup power—requiring sophisticated control algorithms and compliance with grid interconnection standards (IEEE 1547, UL 1741). Grid-interactive capabilities maximize system value while ensuring utility grid safety.

APTPCB manufactures assemblies with comprehensive grid-interactive features.

Key Grid Control Capabilities

- Grid Synchronization: Precision phase-locked loops achieving fast, stable synchronization to grid voltage enabling seamless transition between grid-connected and islanded operation.

- Power Factor Control: Active and reactive power control providing power factor correction and voltage support services to grid operators.

- Anti-Islanding Protection: Rapid islanding detection meeting IEEE 1547 requirements preventing energizing isolated grid sections during utility outages.

- Frequency/Voltage Regulation: Automatic adjustment of power output responding to grid frequency or voltage deviations supporting grid stability.

- Communication Protocols: Modbus, SunSpec, or proprietary interfaces enabling aggregation and control by virtual power plant (VPP) operators.

- Firmware Updateability: Remote firmware updates enabling new features, grid code compliance, and performance optimization post-deployment.

Advanced Grid Services

Through sophisticated control implementation and functional testing, APTPCB delivers ESS assemblies providing valuable grid services maximizing system economics.

Ensuring Safety and Protection Systems

Energy storage systems require comprehensive safety systems protecting personnel, equipment, and property from electrical hazards, thermal events, and fault conditions. Multi-layer protection implementation ensures safe operation across all operating modes and failure scenarios.

APTPCB implements comprehensive safety and protection circuits.

Key Safety Implementation

- Ground Fault Detection: High-sensitivity ground fault monitoring detecting insulation failures enabling rapid shutdown preventing electric shock hazards.

- Arc Flash Protection: Arc fault detection circuits identifying dangerous arcing conditions triggering immediate disconnection preventing fire hazards.

- Thermal Monitoring: Multiple temperature sensors monitoring power electronics, battery interface, and enclosure temperature triggering protection at safe thresholds.

- Overcurrent Protection: Fast-acting overcurrent detection protecting power semiconductors and battery during short circuit or overload conditions.

- Emergency Shutdown: Hardware emergency stop ensuring complete system de-energization independent of software control.

- Safety Certification: Manufacturing processes and documentation supporting UL 1741, UL 9540, and regional safety certifications.

Multi-Layer Safety Protection

By implementing comprehensive safety systems and quality inspection, APTPCB delivers ESS assemblies meeting stringent safety requirements for residential and commercial installations.

Executing Comprehensive System Testing

Energy storage validation requires testing power conversion efficiency, grid compliance, BMS integration, protection circuits, and thermal performance under realistic operating conditions. Thorough testing prevents field failures and ensures reliable operation across diverse applications.

APTPCB provides dedicated ESS test capabilities.

Key Testing Requirements

- Efficiency Mapping: Testing across charge/discharge power levels and battery voltage ranges verifying >95% round-trip efficiency targets.

- Grid Compliance Testing: Validating voltage/frequency response, power factor control, and anti-islanding protection meeting IEEE 1547 requirements.

- BMS Communication: Verifying CAN bus communication, safety interlocks, and coordinated operation with battery management systems.

- Protection Validation: Triggering overcurrent, ground fault, arc fault, and thermal conditions verifying proper protective responses.

- Thermal Performance: Full-power testing with temperature monitoring verifying designs maintain safe operating temperatures.

- Environmental Stress: Temperature cycling and burn-in identifying early failures and validating long-term reliability.

Validated System Performance

Through comprehensive testing and incoming quality control, APTPCB delivers ESS assemblies meeting efficiency, safety, and reliability specifications.

Supporting Flexible Production for Diverse Markets

Energy storage markets span residential battery backup, commercial peak shaving, grid-scale frequency regulation, and microgrid applications requiring manufacturing flexibility supporting diverse specifications, power levels, and customization requirements.

APTPCB provides scalable production from prototypes through volume manufacturing.

Key Production Capabilities

- Rapid Development: NPI assembly delivering functional prototypes supporting certification testing and customer demonstrations.

- Power Level Scaling: Flexible manufacturing accommodating power ratings from 5kW residential systems through 100kW+ commercial installations.

- Volume Production: Mass production capability supporting thousands of units annually with consistent quality and competitive pricing.

- Component Engineering: Component sourcing managing IGBTs, capacitors, and specialized power components ensuring material availability.

- Certification Support: Manufacturing documentation supporting UL 9540, IEEE 1547, and regional certifications enabling global market access.

- Technical Support: Engineering assistance with power electronics design, control algorithms, and manufacturing throughout product lifecycle.

Responsive Manufacturing Partnership

Through flexible capabilities and support services, APTPCB enables energy storage manufacturers serving diverse markets efficiently. Our power energy experience supports successful ESS product programs globally.