Quick Answer (30 seconds)

Designing or sourcing a Gantry Control PCB requires balancing high-power motor driving with sensitive feedback signal integrity.

- Synchronization is critical: The PCB layout must support dual-drive logic (master/slave) with zero latency to prevent mechanical skewing of the gantry beam.

- Noise immunity: Encoder signals run through long drag chains; the PCB must utilize differential pair routing and dedicated ground planes to reject EMI.

- Vibration resistance: Gantry systems are dynamic. Use locking connectors (Molex/JST) and consider mixed-technology assembly (SMT + rugged THT) for high-stress components.

- Thermal management: Motor drivers integrated onto the Gantry Control PCB require heavy copper (2oz+) or metal-core substrates to dissipate heat without active cooling.

- Power isolation: Physically separate high-voltage motor rails (24V/48V) from 3.3V/5V logic to prevent controller resets during braking (back-EMF).

- Validation: Always perform functional testing for "following error" and "skew detection" before mass production.

When Gantry Control PCB applies (and when it doesn’t)

Gantry systems differ from standard single-axis motion because they often drive one mechanical axis with two motors (Y1 and Y2). The PCB must handle this coordination.

When to use a specialized Gantry Control PCB:

- Dual-Drive Systems: CNC routers, laser cutters, or pick-and-place machines where a heavy beam is moved by motors on both ends.

- High-Speed Motion: Applications requiring real-time feedback loops (PID) where signal latency on the PCB must be minimized.

- Integrated Heads: When the print head, spindle, or sensor array needs a local breakout board (Actuator Control PCB) mounted directly on the moving gantry.

- Complex I/O: Systems requiring synchronized control of auxiliary devices like a Control Valve PCB for pneumatics or vacuum solenoids alongside motion.

When it is unnecessary (use standard drivers instead):

- Single-Axis Actuators: Simple linear slides where a standard off-the-shelf stepper driver suffices.

- Low-Precision Conveyors: Where mechanical skew is acceptable or the gantry is mechanically linked via a driveshaft rather than electronic synchronization.

- Static Control Panels: If the motion logic is entirely centralized in a remote PLC and the gantry only carries cables, a complex PCB on the gantry itself is not needed.

- Low-Speed Batch Processing: Simple Batch Control PCB logic for fluid filling often does not require the high-speed synchronization of a motion gantry.

Rules & specifications

The following specifications ensure the Gantry Control PCB can withstand the electrical noise and mechanical stress of industrial environments.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Copper Weight | 2 oz (70µm) or higher | Handles high current surges during motor acceleration/deceleration. | Microsection analysis or E-Test. | Traces overheat or fuse open during rapid moves. |

| Trace Width (Power) | > 40 mil per Amp | Prevents voltage drop that causes motor torque loss. | IPC-2221 Calculator check. | Motors lose steps; drivers fault out under load. |

| Differential Impedance | 90Ω or 100Ω ±10% | Critical for RS-422/RS-485 encoder signals to prevent pulse loss. | TDR (Time Domain Reflectometry). | Encoder counts are lost; positioning errors occur. |

| Isolation Gap | > 0.5mm (HV to Logic) | Prevents inductive spikes from motors damaging the MCU. | High-pot test / Visual inspection. | Logic crashes or permanent MCU damage. |

| Via Tenting | Plugged or Tented | Prevents shorting from conductive dust or debris in machining environments. | Visual inspection. | Intermittent shorts causing system resets. |

| Connector Rating | High-vibration / Locking | Gantry motion creates constant vibration; standard headers will walk out. | Shake/Vibration test profile. | Intermittent connection failures during operation. |

| Ground Plane | Solid, Unbroken | Provides return path for noise; essential for Conductivity Control PCB sections. | Gerber review (layer view). | EMI causes false sensor triggers or communication loss. |

| Thermal Vias | Under Driver Pads | Transfers heat from FETs/Drivers to inner/bottom layers. | X-Ray inspection. | Drivers overheat and shut down thermally. |

| Solder Mask | Matte Green/Black | Reduces glare for automated optical inspection (AOI); matte resists scratching. | Visual check. | Minor aesthetic issue; gloss can fatigue manual inspectors. |

| Material Tg | > 170°C (High Tg) | Prevents pad lifting during rework or high-temp operation. | Datasheet verification. | PCB delamination in hot industrial enclosures. |

Implementation steps

Designing and deploying a reliable Gantry Control PCB involves strict adherence to signal integrity and mechanical constraints.

- Define Motion Profile: Determine the peak current and continuous current for the gantry motors. This dictates the copper weight and trace width.

- Schematic Capture (Dual Loop): Design the schematic to support dual-feedback loops if using dual motors. Ensure the MCU has dedicated quadrature encoder inputs for both axes.

- Component Placement: Place high-current motor drivers near the power entry connector. Place the MCU and sensitive Control Panel PCB interfaces as far as possible from the motor drivers.

- Routing Critical Signals: Route encoder and communication lines (EtherCAT, CAN bus) as differential pairs first. Do not cross splits in the ground plane.

- Power Plane Design: Create wide polygons for V_MOTOR and GND. Use a star-ground topology to separate "noisy" motor ground from "quiet" logic ground.

- Mechanical Fit Check: Export the 3D PCB model. Verify clearance for the gantry housing, especially for tall capacitors and connectors.

- DFM Review: Send Gerbers to APTPCB (APTPCB PCB Factory) for a Design for Manufacturing check. Focus on minimum annular rings and copper-to-edge clearance.

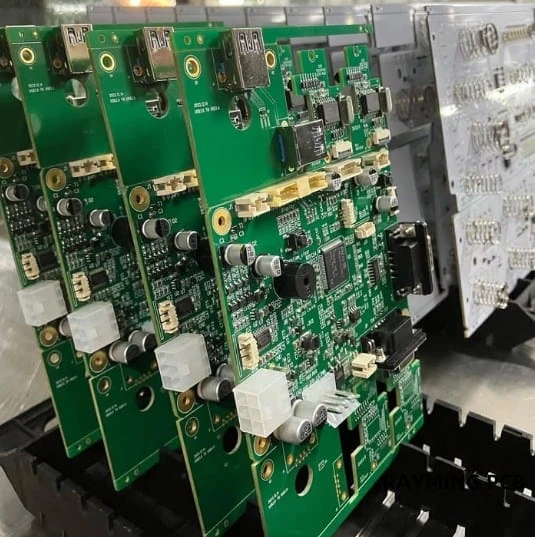

- Prototype Fabrication: Order a small batch (5-10 units). Specify controlled impedance if using high-speed encoders.

- Bench Testing: Power up with current limiting. Test logic communication before enabling high-voltage motor power.

- Load Testing: Install on the gantry. Run "burn-in" cycles (rapid back-and-forth motion) to test thermal performance and connector stability.

Failure modes & troubleshooting

Gantry systems are prone to specific failures due to movement and noise.

1. Gantry Skewing (One side lags)

- Symptom: The gantry binds or twists; motors fight each other.

- Causes: High resistance in one motor trace; signal loss in one encoder channel; mechanical binding.

- Check: Measure resistance from driver output to motor connector. Verify trace width consistency.

- Fix: Reinforce traces with solder or jumper wire (prototype); redesign for wider traces (production).

2. Intermittent Encoder Errors

- Symptom: Position loss or "jumpy" motion.

- Causes: EMI noise coupling into encoder lines; impedance mismatch.

- Check: Use an oscilloscope to check signal squareness. Look for ringing.

- Fix: Add termination resistors (120Ω). Ensure differential pairs are length-matched.

3. Driver Overheating

- Symptom: Axis shuts down after 10-20 minutes of operation.

- Causes: Insufficient thermal relief; poor heatsink contact.

- Check: Measure PCB temperature near driver pad.

- Fix: Use Heavy Copper PCB technology or aluminum-backed substrates. Add thermal vias.

4. Connector Burnout

- Symptom: Charred plastic around power connectors.

- Causes: Connector rated current exceeded; fretting corrosion from vibration.

- Check: Inspect contact plating. Verify current rating vs. actual load.

- Fix: Switch to high-current industrial connectors (e.g., Phoenix Contact, Molex Mega-Fit).

5. Logic Resets during Braking

- Symptom: MCU reboots when the gantry stops suddenly.

- Causes: Back-EMF spikes feeding back into the logic supply.

- Check: Monitor 5V/3.3V rail during deceleration.

- Fix: Add flyback diodes and bulk capacitance. Improve isolation between HV and LV grounds.

Design decisions

Successful Gantry Control PCB projects often hinge on architectural decisions made early in the process.

Centralized vs. Distributed Control Should the drivers be on the gantry or in the cabinet?

- Cabinet (Remote): Keeps the PCB on the gantry simple (just a breakout). Better for thermal management but requires long, expensive motor cables.

- On-Gantry (Local): Reduces cabling to just power and comms. Requires a robust Actuator Control PCB capable of handling vibration and heat. This is the modern trend for modular machines.

Rigid vs. Rigid-Flex For the connection between the moving gantry and the stationary frame:

- Cables in Drag Chain: Standard solution. Low cost, but cables eventually fatigue.

- Rigid-Flex PCB: Eliminates connectors and cables. Extremely reliable for millions of cycles but higher initial tooling cost. Best for compact medical or aerospace gantries.

Integration of Auxiliary Functions Modern gantries often carry more than just a tool head.

- Fluid Control: Integrating drivers for a Control Valve PCB directly onto the main gantry board saves space and wiring complexity.

- Sensing: On-board inputs for Conductivity Control PCB circuits (for liquid handling gantries) reduce the need for separate sensor modules.

FAQ

Q: What is the best surface finish for a Gantry Control PCB? A: ENIG (Electroless Nickel Immersion Gold) is recommended. It provides a flat surface for fine-pitch driver components and excellent corrosion resistance for industrial environments.

Q: How do I handle the high current requirements for NEMA 34 or larger motors? A: Use wide traces on outer layers or 2oz/3oz copper on inner layers. For very high current (>10A), consider soldering copper bus bars onto the PCB or using Industrial Control PCB standards with heavy copper.

Q: Can I route encoder signals next to motor power traces? A: No. Motor power traces carry high-frequency switching noise (PWM). Keep encoder signals at least 50 mils away from power traces, preferably separated by a ground plane.

Q: What is the difference between an Actuator Control PCB and a Gantry Control PCB? A: An Actuator Control PCB typically drives a single axis or end-effector. A Gantry Control PCB coordinates multiple axes (often synchronized) and manages the kinematics of the entire beam movement.

Q: Why does my gantry PCB fail during the "E-Stop" test? A: Emergency stops cut power abruptly, causing inductive loads (motors) to dump energy. Without sufficient TVS diodes or clamp circuits, this voltage spike destroys driver chips.

Q: Do I need impedance control for stepper motor signals? A: Not for the motor power lines, but absolutely yes for the step/direction or fieldbus (EtherCAT/CAN) signals controlling the drivers.

Glossary (key terms)

| Term | Definition |

|---|---|

| Gantry | A bridge-like overhead structure with a platform supporting equipment such as a crane, camera, or tool head. |

| Dual-Loop Control | A control method using feedback from both the motor shaft and a linear scale on the load to correct backlash. |

| Back-EMF | Voltage generated by a spinning motor when it acts as a generator (e.g., during braking), potentially damaging the PCB. |

| Differential Pair | Two complementary signals (D+ and D-) used to transmit data with high immunity to external noise. |

| Drag Chain | A flexible track that guides and protects cables/hoses connected to the moving gantry. |

| Skew | The misalignment between the left and right sides of a gantry, causing mechanical binding. |

| PWM (Pulse Width Modulation) | A method of controlling power to the motors by switching the voltage on and off rapidly. |

| Creepage | The shortest distance between two conductive parts along the surface of the insulation material. |

| Actuator | The component (motor, solenoid) responsible for moving or controlling a mechanism. |

| Gerber Files | The standard file format used by APTPCB to manufacture the PCB layers, mask, and silkscreen. |

Request a quote

Ready to build your Gantry Control PCB? APTPCB specializes in high-reliability boards for industrial automation, offering heavy copper options and strict impedance control.

What to send for a DFM review & Quote:

- Gerber Files (RS-274X): Include all copper layers, drill files, and outline.

- Stackup Requirements: Specify copper weight (e.g., 2oz) and dielectric thickness if impedance is controlled.

- Assembly BOM: If you need PCBA, include the Bill of Materials with manufacturer part numbers.

- Volume: Prototype quantity vs. estimated annual usage.

Conclusion

The Gantry Control PCB is the nervous system of any precision motion platform. Whether you are synchronizing dual servo motors for a CNC router or managing delicate sensor feedback on a medical scanner, the PCB design must prioritize signal integrity, thermal capacity, and vibration resistance. By following strict layout rules—such as isolating high-voltage rails and utilizing differential pairs for feedback—you ensure your gantry operates smoothly without skew or downtime. Trust APTPCB to deliver the manufacturing precision required for these critical industrial control systems.