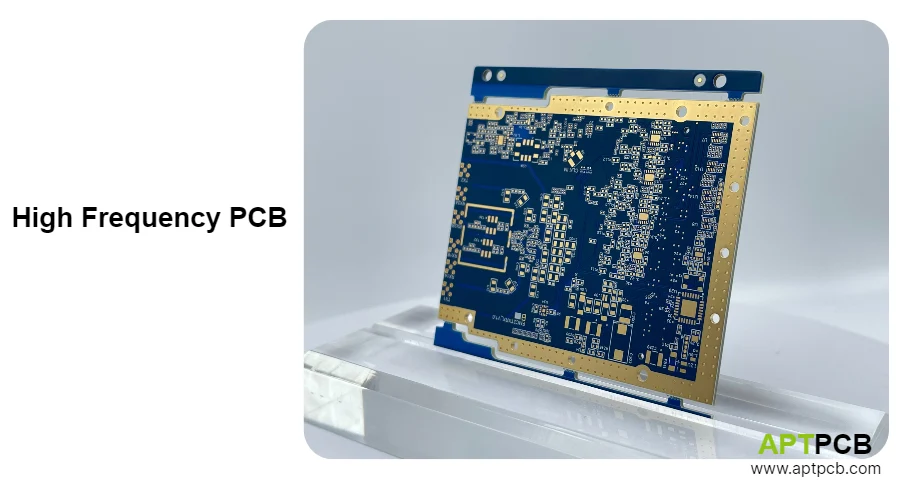

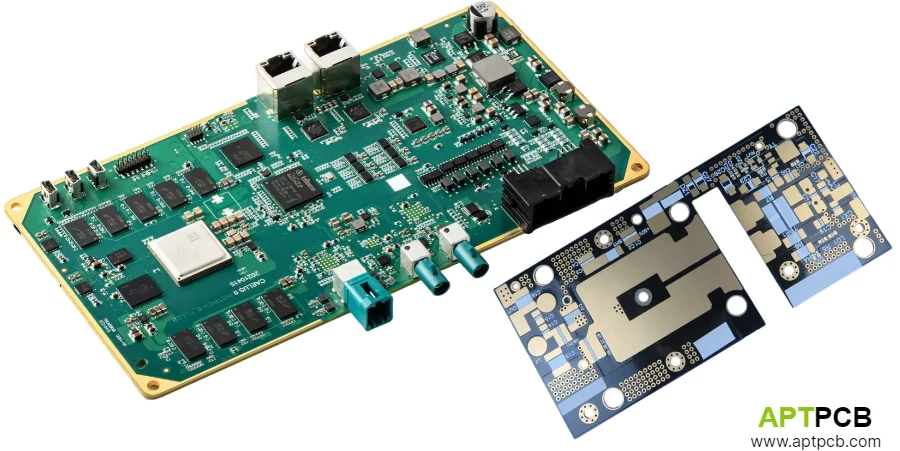

High frequency multilayer printed circuit boards combine complex multilayer construction with demanding high frequency signal integrity requirements. These sophisticated assemblies enable modern radar systems, satellite communications, wireless infrastructure, and high-speed computing platforms providing routing density, power distribution, and electromagnetic shielding while maintaining precise electrical characteristics for reliable operation across the frequency spectrum.

At APTPCB, we manufacture high frequency multilayer PCBs with specialized expertise implementing optimized stackups, sequential lamination, and precision fabrication. Our capabilities support RF high frequency PCB applications with complex layer requirements through validated manufacturing processes ensuring consistent performance.

Optimizing Multilayer Stackup Architecture

Effective multilayer high frequency design begins with thoughtful stackup architecture allocating layer functions and material selections for optimal electrical performance. Signal layers, reference planes, and power distribution must be configured supporting high frequency behavior. Inadequate stackup design causes impedance control difficulties, insufficient isolation between circuits, or electromagnetic coupling degrading performance — directly impacting design success and system reliability.

At APTPCB, our engineering supports optimized stackup design for high frequency applications.

Key Stackup Design Considerations

- Layer Function Allocation: Signal layers adjacent to continuous ground planes maintaining field containment with symmetric construction minimizing warpage during high frequency PCB fabrication thermal processing.

- Reference Plane Design: Continuous ground planes containing electromagnetic fields with minimized openings preventing return current path disruption near high frequency traces.

- Dielectric Layer Configuration: Material selection and thickness determining transmission line impedance and coupling with different materials for different layer functions optimizing performance and cost.

- Hybrid Material Constructions: Low-loss materials for high frequency signal layers combined with cost-effective materials for digital and power layers through low-loss high frequency PCB technology.

- Stackup Documentation: Complete specification including materials, thicknesses, tolerances, and impedance targets ensuring manufacturing understanding.

- DFM Review: Engineering analysis of proposed stackups identifying fabrication challenges and optimization opportunities before release.

Stackup Excellence

Through stackup expertise, material knowledge, and DFM support coordinated with manufacturing capabilities, APTPCB enables high frequency multilayer designs achieving electrical performance requirements.

Implementing Precision Impedance Control

Multilayer high frequency PCBs require controlled impedance on multiple signal layers with single-ended and differential configurations. Manufacturing must achieve specified tolerances across all impedance-controlled structures. Inadequate impedance control causes signal reflections degrading integrity, mismatch between channels affecting balance, or protocol compliance failures — directly impacting circuit functionality and system performance.

At APTPCB, our manufacturing achieves precision impedance control across multilayer structures.

Key Impedance Control Capabilities

- Single-Ended Transmission Lines: Microstrip on outer layers and stripline on internal layers achieving target impedance with controlled impedance high frequency PCB fabrication precision.

- Differential Pair Implementation: Edge-coupled pairs on same layer or broadside-coupled on adjacent layers with consistent spacing maintaining differential impedance.

- Field Solver Analysis: Accurate impedance prediction for complex multilayer geometries accounting for all surrounding conductors and dielectrics.

- Manufacturing Tolerance Management: Statistical analysis predicting impedance variation with design margins accommodating process tolerances.

- Coupon Verification: TDR testing of multiple impedance classes across panel positions confirming achieved values meet specifications.

- Multiple Impedance Classes: Different impedance values on different layers or within same layer with separate coupon verification for each class.

Impedance Control Excellence

By implementing precision fabrication, field solver analysis, and comprehensive verification coordinated with design requirements, APTPCB achieves impedance control meeting demanding multilayer specifications.

Managing Via Transition Performance

Via transitions between layers introduce impedance discontinuities requiring careful management in high frequency multilayer designs. Via barrel inductance, pad capacitance, and stub length affect transition performance. Inadequate via management causes reflections at layer transitions, resonances from via stubs at high frequencies, or excessive insertion loss through transitions — significantly impacting signal integrity and system performance.

At APTPCB, our manufacturing optimizes via transition performance.

Key Via Transition Capabilities

- Via Optimization: Anti-pad sizing and via diameter selection balancing electrical performance with manufacturing requirements for microwave RF PCB applications.

- Ground Via Implementation: Proper ground via placement around signal vias improving transition performance with via fencing containing fields.

- Backdrilling: Controlled-depth drilling removing unused via stubs preventing resonances at high frequencies with depth accuracy within ±50μm achieving minimal stub lengths.

- Blind and Buried Vias: Via structures terminating at internal layers eliminating stub issues with sequential lamination enabling internal via connections.

- Via-in-Pad Design: Component mounting pads directly over vias for space efficiency with via filling preventing solder wicking during assembly.

- Transition Verification: TDR analysis confirming transition performance meets specifications with design optimization based on measurements.

Via Transition Excellence

Through optimized via structures, backdrilling capability, and blind/buried via processing coordinated with design requirements, APTPCB achieves via transition performance supporting demanding high frequency applications.

Executing Sequential Lamination Processes

Complex high frequency multilayer boards often require sequential lamination achieving via structures not possible with single lamination. Sequential build processes add manufacturing complexity requiring precise control at each stage. Inadequate sequential lamination causes registration errors accumulating through builds, reliability issues from process variations, or yield losses from increased complexity — directly impacting product quality and cost.

At APTPCB, our manufacturing executes precision sequential lamination processes.

Key Sequential Lamination Capabilities

- Multi-Stage Build: Laminating subconstructions into final assembly with process planning minimizing cycles while meeting design requirements through high frequency PCB manufacturer expertise.

- Registration Control: Precision tooling maintaining alignment through multiple lamination cycles with cumulative tolerance accounting in via land sizing.

- Material Compatibility: Selection of compatible materials at each lamination interface ensuring reliable bonding between sequential builds.

- Process Documentation: Detailed parameters for each sequential build stage with quality records maintaining traceability.

- Intermediate Testing: Verification at sub-assembly stages identifying issues before additional value commitment.

- Layer Count Capability: High layer count capability supporting complex designs with multiple sequential lamination stages.

Sequential Lamination Excellence

By executing precision sequential lamination, maintaining registration control, and implementing comprehensive process documentation, APTPCB achieves complex multilayer constructions meeting demanding specifications.

Implementing Power Distribution Design

Multilayer high frequency designs require effective power distribution providing stable supply voltages and low impedance return paths. Decoupling strategies must address frequency ranges from DC through the highest operating frequencies. Inadequate power distribution causes supply noise affecting sensitive circuits, ground bounce degrading signal integrity, or resonances in power distribution network — directly impacting system performance and reliability.

At APTPCB, our manufacturing supports effective power distribution implementation.

Key Power Distribution Capabilities

- Power Plane Configuration: Solid planes adjacent to high-current components with interleaved power and ground minimizing loop inductance for RF circuit board manufacturing applications.

- Decoupling Implementation: Via connections for decoupling capacitors minimizing connection inductance with multiple vias per capacitor reducing high-frequency impedance.

- Split Plane Management: Plane splits separating power domains without disrupting return current paths beneath high frequency signals.

- Heavy Copper Options: 2-4 oz copper for power distribution layers handling high currents with minimal voltage drop.

- Thermal Via Integration: Via arrays transferring heat from power devices to thermal spreader planes supporting power handling requirements.

- PDN Simulation Support: Design verification ensuring power distribution impedance meets requirements across frequency with manufacturing implementation.

Power Distribution Excellence

Through comprehensive power distribution implementation, heavy copper capability, and thermal via integration coordinated with design requirements, APTPCB enables multilayer power distribution meeting demanding specifications.

Supporting Embedded Passive Integration

Embedded passive technology integrates capacitors, resistors, and inductors within multilayer structures reducing assembly complexity and improving high frequency performance. Manufacturing embedded elements requires additional process steps and controls. Inadequate embedded passive implementation causes component value variations affecting circuit performance, reliability issues from material incompatibility, or yield losses from process complexity — impacting product quality and cost.

At APTPCB, our manufacturing supports embedded passive integration.

Key Embedded Passive Capabilities

- Embedded Capacitors: Thin dielectric layers providing distributed decoupling without surface components eliminating surface mount parasitic effects.

- Embedded Resistors: Resistive material layers for termination and biasing functions with value accuracy meeting design requirements.

- Material Compatibility: Embedded passive materials compatible with overall lamination processes maintaining reliability.

- Design Rules: Feature size and spacing requirements for embedded elements based on process capability.

- Value Tolerance: Achievable tolerances for embedded resistors and capacitors with design margins accommodating variation.

- Testing Verification: In-process and final testing confirming embedded element values meet specifications through testing quality protocols.

Embedded Passive Excellence

By implementing embedded passive capabilities, material qualification, and value verification coordinated with design requirements, APTPCB enables high frequency multilayer PCBs with integrated passive elements.

Ensuring Quality and Testing Rigor

High frequency multilayer PCB quality depends on comprehensive testing throughout fabrication and final verification confirming electrical and mechanical specifications. Complex constructions require thorough inspection. Inadequate quality assurance misses defects affecting reliability, provides insufficient data for process control, or lacks documentation for quality investigations — impacting product quality and customer confidence.

At APTPCB, our quality implements rigorous testing for multilayer verification.

Key Quality Capabilities

- Impedance Testing: TDR verification of all impedance classes with statistical analysis across panel positions confirming specifications.

- Electrical Testing: Continuity and isolation verification ensuring circuit integrity with high-voltage testing confirming dielectric integrity.

- Cross-Section Analysis: Microsection examination of layer registration, via quality, and plating thickness with photographic documentation.

- X-Ray Inspection: Non-destructive imaging of internal features including via fill and embedded structures.

- First Article Inspection: Comprehensive dimensional and electrical verification with formal documentation per AS9102 for aerospace defense requirements.

- Traceability Documentation: Complete material and process records supporting quality investigations and regulatory requirements.

Quality Excellence

Through comprehensive testing, thorough documentation, and systematic quality systems, APTPCB delivers high frequency multilayer PCB quality meeting demanding commercial, aerospace, and defense specifications.