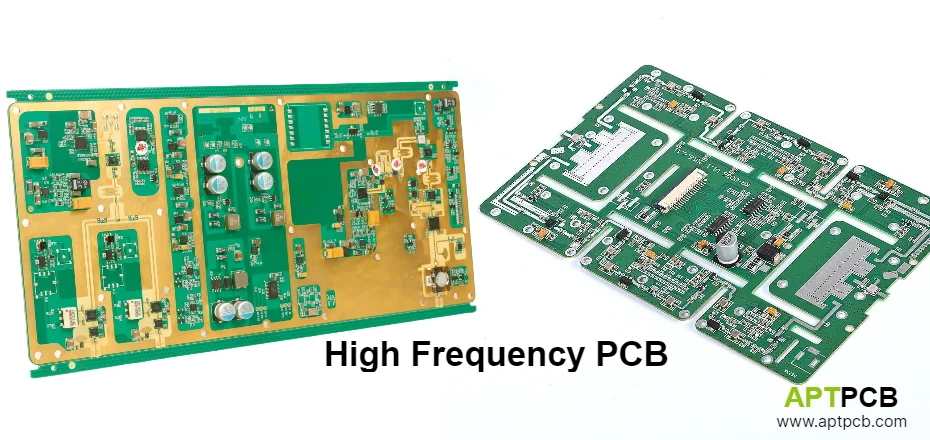

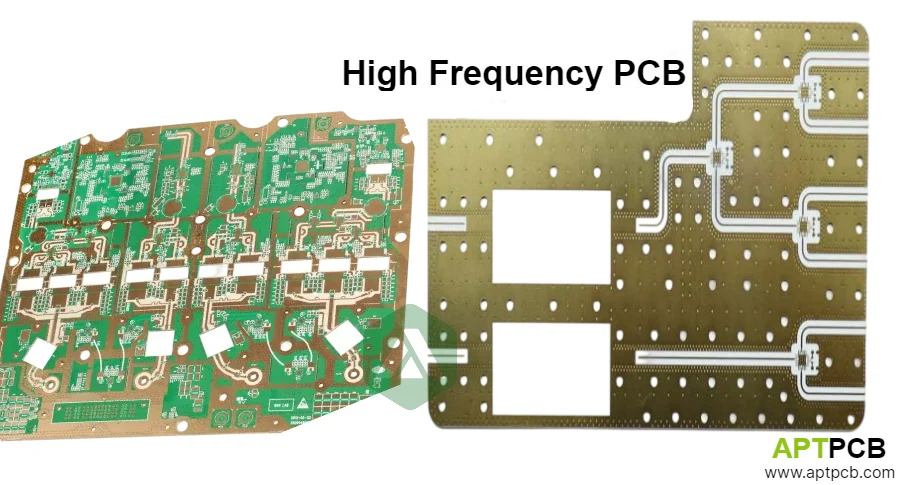

High frequency PCB manufacturing demands specialized expertise combining advanced material processing, precision equipment, and comprehensive quality systems distinguishing capable manufacturers from standard PCB fabricators. Modern wireless communications, radar systems, and satellite applications require manufacturers demonstrating proficiency in PTFE substrate handling, tight impedance control, and thorough RF testing validating electrical performance from megahertz through millimeter-wave frequencies.

At APTPCB, we manufacture high frequency PCBs with specialized infrastructure implementing material-specific processes, precision fabrication equipment, and industry certifications. Our capabilities support RF high frequency PCB applications from prototype through volume production with validated manufacturing processes ensuring consistent quality and performance.

Delivering Specialized Material Processing Expertise

High frequency PCB materials including PTFE-based substrates, ceramic-filled laminates, and advanced hydrocarbon materials require modified processing parameters throughout the fabrication cycle differing significantly from standard FR-4. Manufacturers must maintain detailed process specifications for each material type addressing drilling, lamination, plating, and surface preparation requirements. Inadequate material expertise causes delamination during processing, poor hole quality affecting via reliability, or inconsistent dielectric properties impacting electrical performance — directly affecting manufacturing yield and product quality.

At APTPCB, our manufacturing implements validated processes for all major high frequency material systems.

Key Material Processing Capabilities

- PTFE Substrate Handling: Rogers RT/duroid, Taconic TLY, and similar materials with plasma treatment, modified drilling parameters, and specialized lamination cycles preventing delamination through high frequency PCB fabrication expertise.

- Ceramic-Filled Material Processing: Rogers RO3000 series and ceramic-loaded PTFE with drill wear management, adapted etch chemistry, and controlled depth drilling for complex constructions.

- Hydrocarbon Laminate Fabrication: Rogers RO4000 series and Isola Astra with FR-4-compatible processing providing low-loss high frequency PCB performance at reduced manufacturing complexity.

- Mixed Dielectric Construction: Hybrid stackups combining PTFE RF layers with FR-4 digital layers using compatible bonding materials ensuring reliable multi-material lamination.

- Material Conditioning: Baking procedures removing absorbed moisture, plasma treatment enhancing adhesion, and controlled storage maintaining material properties before processing.

- New Material Qualification: Systematic process development for emerging materials including design of experiments, parameter optimization, and production validation through testing quality protocols.

Material Expertise Validation

Through comprehensive material processing expertise, validated parameters for major substrate types, and systematic qualification procedures supported by continuous process improvement, APTPCB demonstrates manufacturing capability across the full range of high frequency PCB materials meeting demanding application requirements.

Maintaining Precision Manufacturing Equipment

High frequency PCB manufacturing requires equipment capabilities significantly exceeding standard PCB production including laser drilling, direct imaging, precision plating, and controlled depth operations. Equipment calibration and maintenance programs ensure consistent accuracy supporting tight tolerance requirements. Inadequate equipment capability causes dimensional errors affecting impedance control, registration problems impacting multilayer alignment, or plating non-uniformity creating electrical variations — directly limiting achievable product specifications.

At APTPCB, our facilities maintain advanced equipment infrastructure supporting demanding high frequency requirements.

Key Equipment Capabilities

- Laser Drilling Systems: CO2 and UV laser drilling achieving microvia diameters to 75μm with position accuracy within ±15μm enabling high-density interconnect structures for high frequency multilayer PCB applications.

- Direct Imaging Equipment: Laser direct imaging eliminating film-related registration errors achieving ±10μm accuracy critical for fine-line RF geometries and controlled impedance high frequency PCB fabrication.

- Controlled Depth Drilling: CNC systems with depth control accuracy within ±50μm enabling backdrilling stub removal to 8 mil supporting frequencies through 40 GHz.

- Precision Plating Systems: Automated plating with pulse reverse capability achieving ±10% thickness uniformity across panel surfaces critical for impedance control.

- Environmental Controls: Temperature stability within ±1°C and humidity control maintaining consistent processing conditions for dimensional accuracy.

- Calibration Programs: Equipment calibration traceable to national standards with documented verification ensuring measurement accuracy through functional testing validation.

Equipment Performance Assurance

By maintaining advanced manufacturing equipment, rigorous calibration programs, and preventive maintenance schedules supported by technical staff expertise, APTPCB delivers precision fabrication capability meeting demanding high frequency PCB specifications across prototype and production volumes.

Implementing Robust Quality Management Systems

High frequency PCB manufacturers serving demanding applications must maintain comprehensive quality management systems certified to international standards. Industry certifications validate manufacturing processes, personnel competence, and continuous improvement practices. Inadequate quality systems cause inconsistent product quality, documentation gaps affecting traceability, or process drift creating specification violations — significantly impacting customer confidence and application reliability.

At APTPCB, our quality management implements certified systems meeting industry-specific requirements.

Key Certification Capabilities

- ISO 9001 Certification: Foundation quality management system ensuring documented processes, corrective action procedures, and management review supporting all manufacturing operations.

- AS9100 Certification: Aerospace and defense quality requirements addressing configuration management, first article inspection, and enhanced traceability for aerospace defense applications.

- IATF 16949 Certification: Automotive quality management requirements supporting radar, V2X communications, and infotainment RF applications with PPAP documentation.

- IPC-6012 Class 3 Compliance: High reliability fabrication requirements with enhanced inspection criteria, tighter tolerances, and extended testing for demanding applications.

- IPC Personnel Certification: Trained inspectors certified to IPC-A-600 and IPC-A-610 standards ensuring consistent workmanship assessment across production.

- NADCAP Accreditation: Special process accreditation for aerospace applications validating plating, non-destructive testing, and other critical processes.

Quality System Excellence

Through comprehensive quality management certification, documented procedures, and continuous improvement programs supported by trained personnel, APTPCB demonstrates quality system capability meeting requirements across commercial, aerospace, defense, and automotive high frequency applications.

Providing Technical Support Services

Leading high frequency PCB manufacturers provide engineering support services helping customers optimize designs for manufacturability, select appropriate materials, and validate performance. Early collaboration between designers and manufacturers reduces development cycles and improves first-pass success. Inadequate technical support causes designs requiring extensive revision, material selections inappropriate for requirements, or manufacturing issues discovered late in development — significantly impacting project schedules and costs.

At APTPCB, our engineering provides comprehensive technical support throughout product development.

Key Support Capabilities

- Design for Manufacturability Review: Engineering analysis identifying fabrication challenges, tolerance concerns, and optimization opportunities before tooling release for RF circuit board manufacturing efficiency.

- Stackup Consultation: Material selection guidance balancing electrical performance, thermal requirements, and cost considerations with validated layer constructions for high frequency multilayer PCB applications.

- Impedance Modeling: Field solver analysis predicting characteristic impedance from proposed geometries with design recommendations achieving target values within manufacturing tolerances.

- Thermal Analysis: Finite element modeling of heat flow from power devices through PCB structures validating thermal design before fabrication commitment.

- Signal Integrity Simulation: Transmission line loss prediction, via transition modeling, and discontinuity analysis supporting design optimization.

- Application Engineering: Guidance on material selection, construction options, and manufacturing approaches optimized for specific microwave RF PCB applications.

Engineering Partnership Value

By providing comprehensive technical support, early design engagement, and application expertise coordinated with manufacturing capabilities, APTPCB enables successful high frequency PCB development reducing iterations and accelerating time to production.

Managing Capacity and Lead Time Requirements

High frequency PCB manufacturers must balance quick-turn prototype demands with volume production requirements while managing specialized material lead times. Capacity planning accounts for longer processing times required by specialty materials and complex constructions. Inadequate capacity management causes missed delivery schedules, prototype delays affecting development timelines, or production shortages impacting customer supply chains — significantly affecting project success and business relationships.

At APTPCB, our operations implement effective capacity management supporting diverse customer requirements.

Key Capacity Management Practices

- Dedicated Prototype Lines: Separate quick-turn prototype processing enabling 5-10 day delivery without disrupting production schedules for development programs requiring rapid iteration.

- Material Inventory Management: Strategic stocking of common high frequency materials including Rogers, Taconic, and Isola substrates reducing material-related lead times through supply chain partnerships.

- Production Planning: Capacity allocation balancing prototype flexibility with production volume commitments ensuring on-time delivery across order types.

- Multi-Lamination Scheduling: Process planning for sequential build constructions requiring multiple lamination cycles accounting for extended fabrication times.

- Testing Resource Allocation: Network analyzer and TDR testing capacity supporting comprehensive verification of controlled impedance high frequency PCB performance without creating bottlenecks.

- Surge Capacity: Scalable production capability handling volume increases through additional shifts and qualified subcontractor partnerships when required.

Delivery Performance

Through effective capacity management, material inventory strategies, and production planning supported by operational flexibility, APTPCB delivers reliable lead times from prototype through volume production supporting customer development schedules and supply chain requirements.

Supporting Comprehensive Testing and Documentation

High frequency PCB applications require thorough electrical testing validating impedance control, insertion loss, and isolation specifications beyond standard continuity verification. Complete documentation supports quality assurance, traceability, and customer requirements. Inadequate testing misses electrical defects affecting system performance, while incomplete documentation complicates quality investigations and regulatory compliance — impacting product reliability and customer satisfaction.

At APTPCB, our testing provides comprehensive verification with complete documentation packages.

Key Testing Capabilities

- Time Domain Reflectometry: TDR measurement of characteristic impedance along transmission line test coupons with statistical reporting across panel positions validating controlled impedance high frequency PCB fabrication.

- Network Analyzer Testing: S-parameter characterization including insertion loss, return loss, and isolation measurements when specified for critical RF high frequency PCB applications.

- Microsection Analysis: Cross-sectional examination verifying layer registration, plating quality, and via integrity with dimensional measurement and photographic documentation.

- Automated Optical Inspection: High-resolution imaging detecting conductor defects, width variations, and spacing violations on outer and inner layers.

- First Article Inspection: Comprehensive dimensional and electrical verification of initial production with formal FAI documentation per AS9102 requirements.

- Traceability Documentation: Complete material and process records linking finished products to raw materials, equipment, and operator records supporting quality investigations.

Quality Documentation

Through comprehensive testing, thorough documentation, and systematic data management supported by quality system requirements, APTPCB provides high frequency PCB products with verification records meeting commercial, aerospace, and defense customer expectations.