Contents

- The Context: What Makes Hires Audio Certification PCB Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Hires Audio Certification PCB (What to Send)

- Conclusion

"Good" in this context is defined by invisibility. The PCB should contribute zero coloration, negligible crosstalk, and absolute thermal stability under load. Achieving this requires a holistic approach where stack-up design, material selection, and assembly precision converge to create an electrically quiet foundation for sensitive electronics.

Highlights

- Signal Integrity is Physical: How trace geometry and layer stacking directly influence Total Harmonic Distortion (THD) and Signal-to-Noise Ratio (SNR).

- The Grounding Paradox: Why star grounding isn't always the answer in mixed-signal high-resolution designs.

- Material Impact: The role of glass weave and resin properties in preventing microphonic effects and dielectric losses.

- Manufacturing Precision: How APTPCB (APTPCB PCB Factory) controls etching and plating to ensure consistent impedance for high-speed digital audio streams (I2S, USB).

The Context: What Makes Hires Audio Certification PCB Challenging

Designing for high-resolution audio is deceptively difficult because it sits at the intersection of sensitive analog signals and aggressive high-speed digital processing. In the past, audio equipment was bulky, allowing engineers to physically separate the noisy power supply from the delicate preamp stage by inches of air. Today, modern consumer expectations demand compact, sleek devices—soundbars, portable DACs, and wireless earbuds—where those distinct circuit blocks must coexist on a single, high-density board.

The challenge is twofold: bandwidth and dynamic range. Standard audio stops at 20kHz, but Hi-Res certification requires linearity well beyond 40kHz. At these frequencies, the PCB traces begin to act less like simple wires and more like transmission lines, susceptible to skin effect and dielectric absorption. Furthermore, the dynamic range of 24-bit audio implies a theoretical noise floor of -144dB. In reality, achieving even -120dB requires a PCB layout that is immune to external EMI and internal power rail switching noise.

Cost pressure adds another layer of complexity. While audiophile boutique brands might afford exotic ceramic substrates, mass-market devices seeking certification must achieve similar performance using standard FR4 materials. This forces engineers to rely on superior layout techniques and precise manufacturing controls rather than brute-forcing the problem with expensive materials.

The Core Technologies (What Actually Makes It Work)

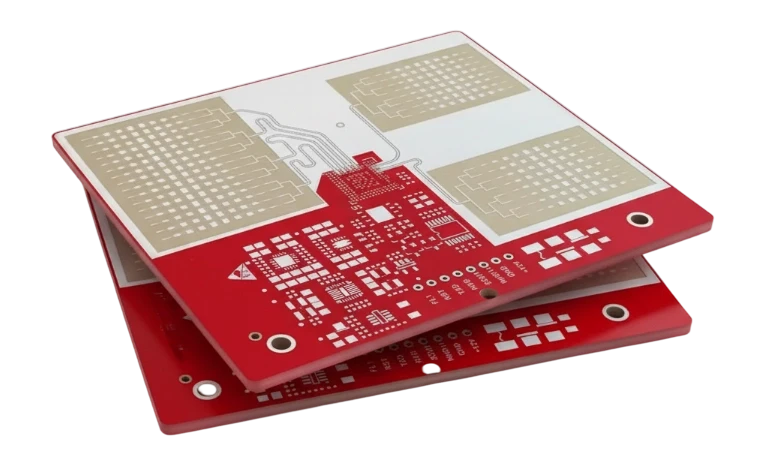

To pass certification, the PCB must act as a fortress for the audio signal. Several core technologies and design philosophies make this possible.

Optimized Layer Stack-up and Grounding: The foundation of any quiet audio board is the PCB stack-up. In a 4-layer or 6-layer design, dedicating internal planes to ground and power provides a low-impedance return path for currents. However, simply pouring copper isn't enough. Designers often employ "split planes" to separate the dirty digital ground (returning current from the DSP or WiFi module) from the clean analog ground (referencing the DAC and Op-Amps), joining them at a single "star" point near the power supply to prevent digital noise from modulating the analog reference voltage.

Surface Finish Selection: The interface between the component and the board matters. For high-resolution audio, PCB surface finishes like ENIG (Electroless Nickel Immersion Gold) are preferred over HASL (Hot Air Solder Leveling). ENIG provides a perfectly flat surface for fine-pitch components like BGA DACs and ensures consistent contact resistance over time, which is critical for maintaining the low-distortion characteristics required for certification.

Thermal Management and Copper Weight: High-resolution often means high power, especially in Class-D amplification stages. As components heat up, their electrical characteristics drift, potentially introducing distortion. Using heavy copper PCB technology (2oz or 3oz copper) helps spread heat laterally across the board, reducing hot spots without the need for bulky heatsinks. This thermal stability ensures that the amplifier operates in its linear region, preserving the audio fidelity.

EMI Shielding and Via Stitching: To protect the analog signal from external RF interference (like WiFi or Bluetooth signals on the same board), engineers use "via stitching" or "picket fences"—rows of ground vias connecting top and bottom ground planes to create a Faraday cage around sensitive traces. This is essential for passing the EMI portion of certification while maintaining a low noise floor.

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

A hires audio certification pcb rarely operates in isolation. It is usually the heart of a larger ecosystem involving power management, user interface, and connectivity modules.

The Power Supply Interaction: The cleanest audio PCB will fail if fed by a noisy power supply. Often, the main audio board connects to a separate power supply unit (PSU) or has an integrated switching regulator. The layout must account for the switching frequency of the regulator. If the switcher operates at 100kHz, its harmonics can bleed into the audio band if not properly filtered. We often see designs utilizing metal core PCB technology for the PSU section to handle heat and provide shielding, connected to the main audio board via shielded headers.

Digital Interfaces and Impedance: Hi-Res audio enters the board digitally via USB, Optical, or HDMI. These are high-speed differential pairs that require strict impedance control (e.g., 90 ohms for USB). If the manufacturing process varies the trace width or dielectric thickness, impedance mismatches occur, causing jitter. While jitter is a digital timing error, in the D/A conversion process, it manifests as audible distortion. Therefore, the PCB fabrication process must be tightly controlled to ensure these digital lanes are within tolerance.

Assembly Cleanliness: The PCBA stage is critical. Flux residues left on the board after soldering can be slightly conductive and hygroscopic (absorbing moisture). In high-impedance analog circuits, this leakage current can create crackling noises or DC offsets that ruin the dynamic range. High-end audio boards often require specialized washing processes and Ionic Contamination testing to ensure the substrate is chemically clean before conformal coating.

Comparison: Common Options and What You Gain / Lose

When specifying a PCB for Hi-Res Audio, engineers face several trade-offs. Is it better to use a standard FR4 material to save cost, or upgrade to a high-frequency laminate? Should the board be 2 layers to simplify assembly, or 4+ layers to improve shielding?

The following matrix outlines how these technical choices translate into practical outcomes for certification and performance.

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| Standard FR4 vs. High-Speed Material (e.g., Rogers/Isola) | Standard FR4 is cost-effective but has higher dielectric loss (Df), which can slightly attenuate high-frequency harmonics. High-speed materials preserve signal integrity for >192kHz sampling rates but increase BOM cost significantly. |

| 2-Layer vs. 4-Layer Stack-up | 2-layer boards struggle with ground loops and EMI, making -100dB SNR difficult. 4-layer boards allow for dedicated ground planes, drastically reducing noise floor and simplifying certification compliance. |

| HASL vs. ENIG Surface Finish | HASL is uneven and can cause poor seating for fine-pitch audio processors. ENIG offers a flat, oxidation-resistant surface, ensuring reliable solder joints and consistent contact resistance for years. |

| Thick Copper (2oz+) vs. Standard (1oz) | Thick copper lowers trace resistance (improving damping factor) and aids thermal dissipation for amplifiers, but limits fine-pitch routing capability for digital control lines. |

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

Reliability in audio isn't just about the board not breaking; it's about the board sounding the same in Year 5 as it did in Year 1.

Signal Integrity and Crosstalk: In a multi-channel environment (like a 7.1 surround receiver), crosstalk between channels destroys the stereo image. This is often caused by capacitive coupling between parallel traces. At APTPCB, we recommend strict spacing rules—often "3W" (three times the trace width)—between aggressive digital lines and sensitive analog inputs. Furthermore, differential pairs for audio data must be length-matched to prevent phase shifts.

Thermal Cycling and Mechanical Stress: Audio equipment, especially amplifiers, undergoes significant thermal cycling. A device might go from room temperature to 60°C during a movie and back down. This expansion and contraction stress the solder joints and the PCB vias. Using high-Tg PCB material (Glass Transition Temperature >170°C) ensures the board expands at a rate similar to the copper, preventing barrel cracks in vias that would cause intermittent signal loss—a nightmare for any audiophile.

Power Delivery Network (PDN): A "stiff" power supply is crucial for transient response (the ability to reproduce a sudden drum hit). The PCB traces connecting the bulk capacitors to the amplifier chips must have minimal inductance. Wide pours and multiple vias in parallel are used to reduce this impedance. If the PDN impedance is too high, the voltage rails will sag during bass notes, causing muddy low-frequency response.

Testing and Verification: Verification goes beyond standard electrical tests. For Hi-Res boards, testing quality involves checking for micro-shorts that might not cause a hard failure but introduce noise. Automated Optical Inspection (AOI) is standard, but functional testing often involves running a test tone through the assembled board and measuring the output on an audio analyzer to catch assembly-related defects before the unit is fully boxed.

The Future: Where This Is Going (Materials, Integration, Ai/automation)

The definition of "High Resolution" is evolving. We are moving from wired, heavy components to wireless, integrated, and smart audio solutions. This shift demands PCBs that can handle RF frequencies (for WiFi 7 and Bluetooth LE Audio) alongside pristine analog signals.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Wireless Audio Latency | ~30-100ms (Bluetooth) | <5ms (Ultra-Wideband / WiFi 7) | Requires PCBs with tighter RF impedance control and mixed-material stack-ups (hybrid FR4 + Rogers). |

| Integration Density | Discrete DAC + Amp + DSP | Single-chip Smart Audio SoCs | PCBs will need HDI (High Density Interconnect) technology to route fine-pitch SoCs without increasing board size. |

| Power Efficiency | 85-90% (Class D) | 95%+ (GaN-based Class D) | Gallium Nitride (GaN) switches switch faster, requiring PCBs with extremely low parasitic inductance to prevent ringing. |

Request a Quote / DFM Review for Hires Audio Certification PCB (What to Send)

When you are ready to move from prototype to production, or if you need a DFM review to ensure your layout will pass certification, providing the right data is crucial. At APTPCB, we analyze your files not just for manufacturability, but for signal integrity risks.

- Gerber Files (RS-274X): Include all copper layers, soldermask, silkscreen, and drill files.

- Stack-up Requirements: Explicitly state the dielectric material (e.g., Isola 370HR) and required layer thickness for impedance control.

- Impedance Notes: Highlight critical nets (e.g., "USB D+/D- 90Ω diff", "MCLK 50Ω single-ended").

- Surface Finish: Specify ENIG or Hard Gold for contact fingers if applicable.

- Copper Weight: Specify if 2oz or higher is needed for power stages.

- Quantities: Prototype (5-10 pcs) vs. Mass Production targets.

- Special Requirements: Mention if "Ionic Contamination Testing" or specific cleanliness standards are required for the assembly phase.

Conclusion

Achieving the "Hi-Res Audio" badge is a milestone that signals quality to the consumer, but the journey there is paved with physics problems. A hires audio certification pcb is the result of balancing the aggressive speed of modern digital processing with the delicate nature of analog waveforms. It requires a disciplined approach to grounding, material science, and manufacturing consistency.

Whether you are building a flagship audiophile streamer or a mass-market smart speaker, the PCB is the stage upon which your audio performs. By partnering with a manufacturer like APTPCB that understands the nuances of low-noise design and precise fabrication, you ensure that the only thing the end-user hears is the music, exactly as the artist intended.