Contents

- Highlights

- How to Estimate PCB Cost from Gerber: Definition and Scope

- How to Estimate PCB Cost from Gerber Rules and Specifications

- How to Estimate PCB Cost from Gerber Implementation Steps

- How to Estimate PCB Cost from Gerber Troubleshooting

- 6 Essential Rules for How to Estimate PCB Cost from Gerber (Cheat Sheet)

- FAQ

- Request a Quote / DFM Review for How to Estimate PCB Cost from Gerber

- Conclusion

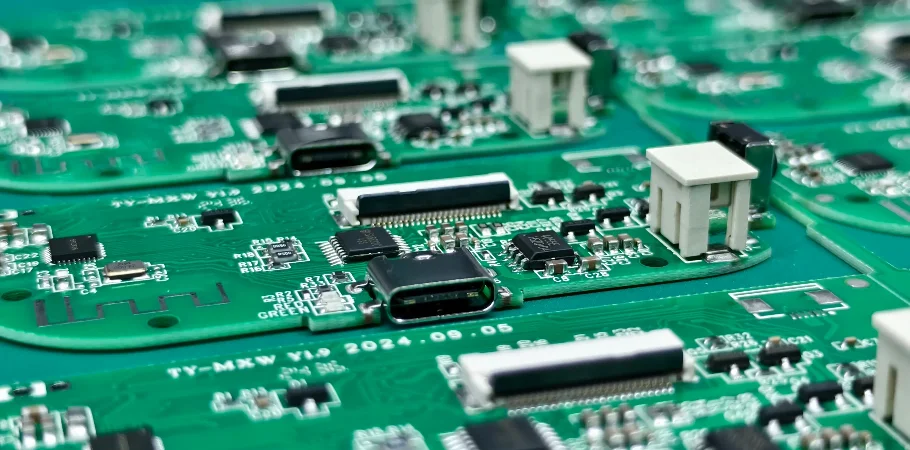

When you upload a design to a manufacturer, the pricing engine doesn't just look at the board dimensions; it parses the raw vector data in your Gerber files to determine complexity. As a Senior CAM Engineer at APTPCB, I often see designers shocked by quotes because they didn't realize a single 3-mil trace or a specific drill aspect ratio pushed their board from "standard" to "advanced" pricing tiers. Learning how to estimate pcb cost from gerber files involves understanding how CAM software interprets your layer data, drill hits, and copper distribution to calculate material usage and machine time.

Quick Answer

To estimate PCB cost from Gerber files, you must analyze five specific data points extracted from the RS-274X files: Board Dimensions (Panelization), Layer Count, Min Trace/Space, Drill Density, and Special Process Requirements.

- Rule: Cost increases non-linearly with layer count; jumping from 4 to 6 layers often adds 30-40% due to the extra lamination cycle.

- Pitfall: Inadvertently including "Via-in-Pad" in your drill file (overlapping drill and copper pad) without specifying it can trigger expensive plugging processes.

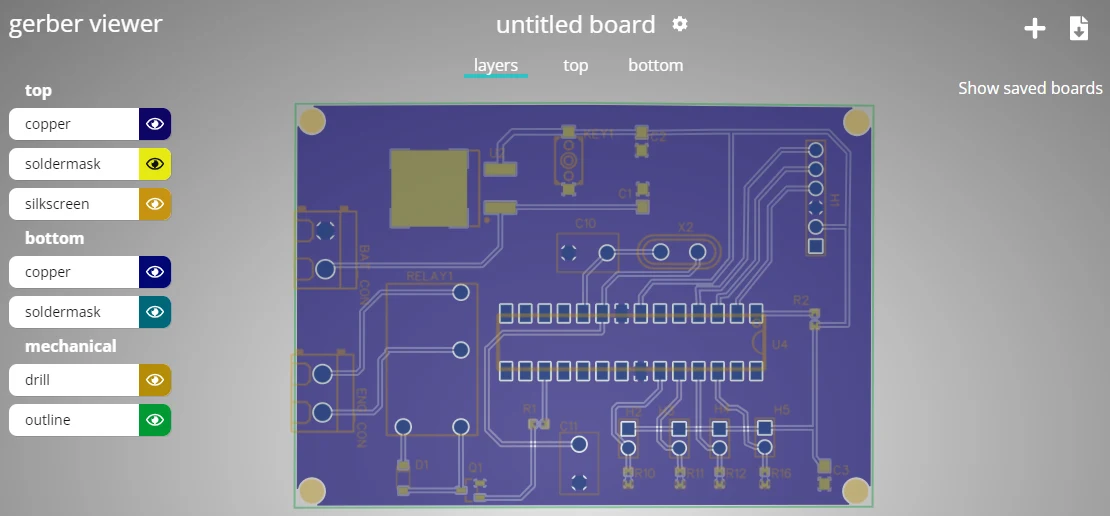

- Verification: Use a Gerber Viewer to measure your tightest trace/space and smallest hole size before quoting. If your smallest feature is 0.1mm (4mil), ensure you aren't paying for 0.075mm (3mil) capabilities unnecessarily.

- Material Factor: High-frequency materials (like Rogers) cost 3-10x more than standard FR4.

- Drill Count: Exceeding standard drill density (e.g., >1000 holes/dm²) increases CNC machine time charges.

Highlights

- Panel Utilization: The single biggest hidden cost driver; poor utilization of the standard working panel (e.g., 18"x24") results in paying for waste material.

- Trace/Space Thresholds: Crossing the threshold from 5mil to 3mil often requires changing from standard etching to Laser Direct Imaging (LDI), spiking costs.

- Drill Aspect Ratio: Holes deeper than 8x their diameter require specialized plating techniques.

- Surface Finish Area: Gold finishes (ENIG/Hard Gold) are priced based on the exposed copper area calculated from the soldermask layer.

How to Estimate PCB Cost from Gerber: Definition and Scope

Estimating cost from Gerbers is the process of "CAM Pre-Analysis." Before a human engineer reviews your board, automated software scans your Gerber files (specifically the copper layers, drill files, and profile layer) to extract manufacturing metrics.

The software looks for "breaches" of standard capabilities. For example, if your copper layer (.GTL) shows a clearance of 3.5 mil, the system flags the board as "HDI" (High Density Interconnect). If your drill file (.DRL) contains 50,000 holes, it calculates the hours required on the CNC machine. Understanding this helps you design for the "sweet spot" of manufacturing—where yield is high and machine time is low.

At APTPCB, our automated quoting tools perform this analysis instantly, but understanding the logic helps you engineer cost out of the board before you even export the files.

Tech / Decision Lever → Practical Impact

| Decision Lever / Spec | Practical Impact (Yield/Cost/Reliability) |

|---|---|

| Layer Count (Standard vs. Custom) | Standard stacks (2, 4, 6, 8) are cheaper due to bulk material stock. Odd layers (e.g., 5) require custom lamination, increasing cost by ~20%. |

| Min Trace/Space (< 4mil) | Triggers HDI pricing. Requires LDI (Laser Direct Imaging) and slower etching speeds to prevent shorts/opens. |

| Drill Size (< 0.2mm) | Mechanical drills break easily below 0.2mm. Smaller holes usually require laser drilling, adding significant machine setup costs. |

| Blind/Buried Vias | Requires sequential lamination (drilling and plating inner layers before final bonding). Can double or triple the bare board cost. |

How to Estimate PCB Cost from Gerber Rules and Specifications

When analyzing your Gerbers, compare your data against these standard manufacturing specifications. Staying within the "Standard" column keeps costs low.

| Rule / Feature | Standard Value (Low Cost) | Advanced Value (High Cost) | Why it matters | How to verify |

|---|---|---|---|---|

| Minimum Trace/Space | ≥ 5 mil / 5 mil | < 3 mil / 3 mil | Tighter spacing reduces yield and requires clean-room class LDI. | Check .GTL/.GBL in Gerber Viewer. |

| Minimum Drill Size | 0.2mm - 0.3mm | < 0.15mm | Small drills have short lifespans and break often, slowing production. | Check .DRL tool list. |

| Annular Ring | ≥ 4 mil | < 3 mil | Requires perfect registration alignment; misregistration causes breakout. | Measure pad diameter vs. hole size. |

| Surface Finish | HASL / HASL LF | ENIG / Hard Gold | Gold is expensive; ENIG involves a complex chemical line. | Check Readme or .GTS (Mask) area. |

| Board Thickness | 1.6mm (0.062") | > 2.0mm or < 0.4mm | Non-standard thicknesses require special stock or handling. | Defined in PCB Stackup. |

| Slots/Cutouts | None / Minimal | Complex / Many | Milling slots takes longer than drilling holes. | Check Profile/Outline layer (.GKO). |

How to Estimate PCB Cost from Gerber Implementation Steps

To accurately predict your costs, follow this step-by-step analysis of your manufacturing files.

Implementation Process

Step-by-step execution guide

Open the mechanical layer (`.GKO` or `.GM1`). Calculate the area. Check if your dimensions fit efficiently onto a standard working panel (e.g., 18"x24"). Poor utilization means you pay for scrap FR4.

Parse the `.DRL` file. Look for hole counts >50/sq. inch. Identify the smallest tool size. If you see 0.1mm holes but don't need [HDI PCB](/pcb/hdi-pcb) technology, increase them to 0.2mm to save cost.

Scan `.GTL` and `.GBL` for trace widths. If you have controlled impedance lines, ensure the dielectric thickness in your stackup matches standard prepreg availability to avoid custom press cycles.

Check for requirements like Castellation (plated half-holes), Hard Gold fingers, or Peelable Mask. These manual processes add fixed costs regardless of board quantity.

How to Estimate PCB Cost from Gerber Troubleshooting

Even with careful design, costs can balloon unexpectedly. Here are common issues found during the Gerber analysis phase.

1. The "Accidental" Blind Via Sometimes, designers export Gerbers where drill pairs are not defined correctly, or they use a "tenting" setting that implies via-in-pad.

- Fix: Ensure your drill file clearly separates through-holes from blind/buried vias. If you don't need blind vias, ensure all drills go from Layer 1 to Layer N.

2. Over-Specifying Tolerances Your title block might say "Tolerance +/- 0.05mm" for the board outline. This requires CNC routing at extremely slow speeds or secondary processing.

- Fix: Use standard routing tolerance (+/- 0.15mm or +/- 0.2mm) unless the board must fit a precision enclosure.

3. Material Selection Mismatch Specifying a specific brand of laminate (e.g., "Isola 370HR") when a generic "High TG FR4" would suffice.

- Fix: Unless you have specific thermal or RF requirements, specify FR4 PCB with "TG150 or equivalent" to allow the factory to use in-stock material.

6 Essential Rules for How to Estimate PCB Cost from Gerber (Cheat Sheet)

| Rule / Guideline | Why It Matters (Physics/Cost) | Target Value / Action |

|---|---|---|

| Standardize Drill Sizes | Every unique drill size requires a tool change on the CNC, adding time. | Consolidate sizes (e.g., make all 0.2mm and 0.25mm holes 0.25mm). |

| Maximize Panel Efficiency | You pay for the whole production panel. Waste = lost money. | >80% Utilization (Ask factory for panel drawing). |

| Avoid Via-in-Pad | Requires conductive/non-conductive filling and capping (POFV). | Dog-bone fanout (if space permits). |

| Surface Finish Choice | Gold is a commodity; prices fluctuate. HASL is a solder dip. | HASL Lead-Free (Cheapest) vs ENIG (Flat/Reliable). |

| Layer Stack Symmetry | Asymmetrical stacks warp during reflow, reducing yield. | Even Layer Counts (2, 4, 6, 8) with balanced copper. |

| Minimum Trace Width | Below 5mil requires higher-resolution imaging equipment. | ≥ 5 mil for standard pricing. |

FAQ

Q: Does the color of the solder mask affect the price?

A: Generally, Green is the standard and cheapest option because it is processed in bulk. Colors like Red, Blue, Black, or White may incur a small setup fee or require longer lead times because they are run in smaller batches. Matte Black often costs slightly more due to the difficulty in inspection and higher rejection rates.

Q: Why is my quote higher than the "calculator" price?

A: Online calculators often assume "Standard Spec." If your Gerbers contain features like half-cut holes (castellation), impedance control, peelable mask, or carbon ink, these trigger manual engineering reviews and additional surcharges.

Q: How does copper weight affect cost?

A: Standard 1oz copper is the baseline. Moving to 2oz or Heavy Copper PCB (>3oz) increases cost significantly because it requires more raw copper, longer etching times (to eat away the thicker copper), and wider spacing rules to prevent short circuits.

Q: Can I reduce cost by panelizing the board myself?

A: Sometimes, but be careful. If you create your own panel array in the Gerber, you might violate the factory's edge rail requirements or fiducial placement rules. It is often better to send the single unit Gerber and ask the factory to panelize it for you (V-score or Tab-route) to ensure it fits their production line efficiently.

Request a Quote / DFM Review for How to Estimate PCB Cost from Gerber

Ready to get an accurate cost for your design? Send your data to APTPCB for a comprehensive DFM review and quote. Ensure your package includes:

- Gerber Files: RS-274X format preferred (Layers: Copper, Solder Mask, Silkscreen, Drill, Outline).

- Drill File: Excellon format, with a tool list.

- Stackup Diagram: If you have impedance requirements or specific layer ordering.

- Readme.txt: Specifying material (e.g., FR4 TG150), thickness (e.g., 1.6mm), surface finish (e.g., ENIG), and copper weight.

- Quantity: Prototype (5-10 pcs) vs. Mass Production (1000+ pcs).

Conclusion

Learning how to estimate pcb cost from gerber files is a critical skill for modern electronics engineers. It moves you from guessing to engineering your costs proactively. By understanding how layer count, drill density, and trace geometry impact the manufacturing process, you can make design decisions that save money without compromising quality. Always verify your Gerbers before submission to ensure no "accidental" high-cost features have slipped into your design.

Signed, The Engineering Team at APTPCB